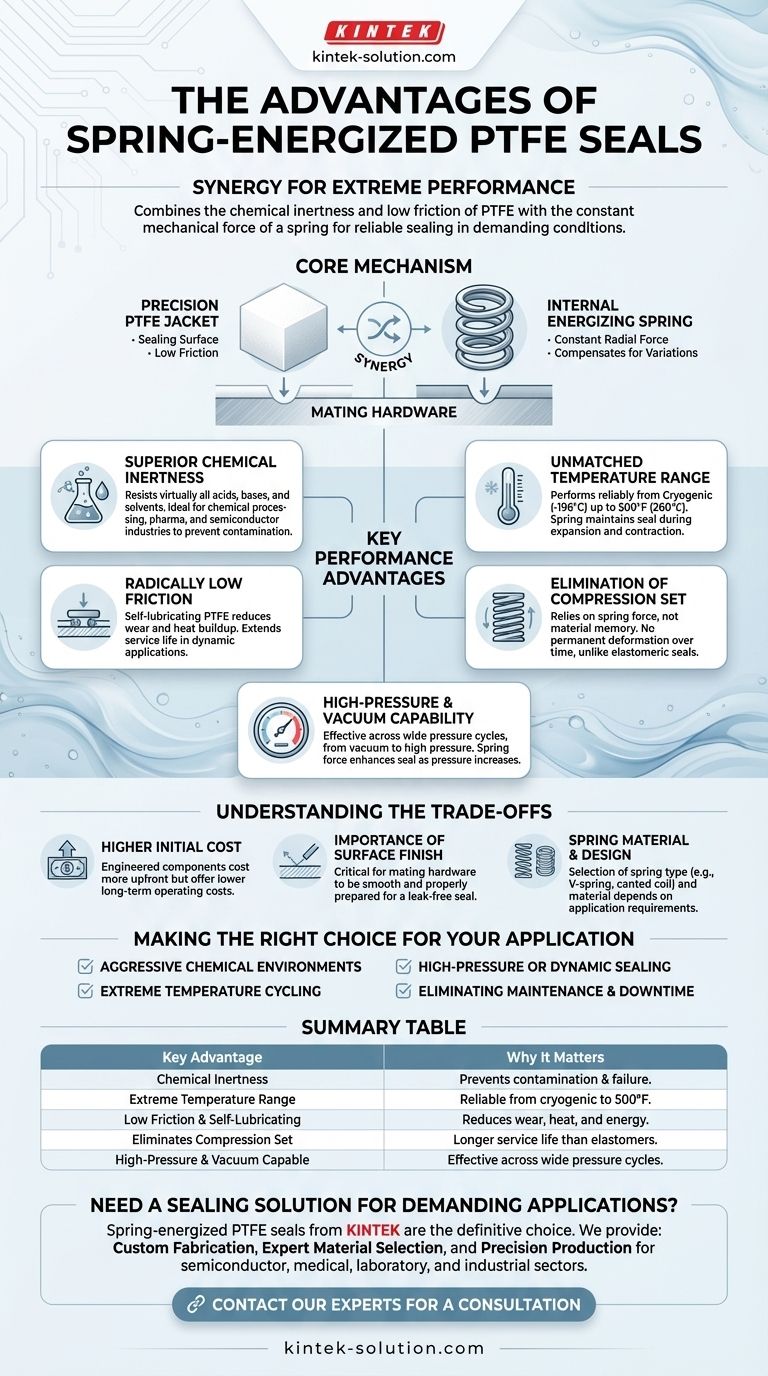

The core advantages of spring-energized PTFE seals lie in their unique ability to combine the material strengths of Polytetrafluoroethylene (PTFE) with the mechanical force of a spring. This creates a highly reliable sealing solution that excels in extreme conditions where conventional elastomeric seals would fail, offering superior chemical compatibility, a vast temperature range, high-pressure capability, and extremely low friction.

The fundamental advantage is not just one feature, but the synergy between the inert PTFE jacket and the resilient internal spring. This combination ensures a constant, reliable sealing force across a wide spectrum of challenging industrial environments.

How Spring-Energized Seals Overcome Common Failures

To understand the benefits of these seals, it’s essential to look at how their construction directly solves the most common points of failure for standard seals like rubber O-rings.

The Core Mechanism: A Spring and a Jacket

A spring-energized seal consists of two key parts: a precision-machined PTFE jacket and an internal energizing spring. The jacket provides the sealing surface, while the spring applies a constant radial force against it.

This design ensures the seal lip remains in firm contact with the mating hardware, compensating for thermal expansion, material wear, and pressure fluctuations.

Superior Chemical Inertness

PTFE is one of the most chemically inert materials known. It is virtually immune to degradation from acids, bases, solvents, and other corrosive fluids.

This makes it the default choice for critical applications in chemical processing, pharmaceutical manufacturing, and the semiconductor industry, where seal failure could lead to contamination or safety hazards.

Unmatched Temperature Range

Standard elastomeric seals have a limited temperature window; they become brittle at low temperatures and degrade quickly at high temperatures.

Spring-energized PTFE seals, however, function reliably in conditions ranging from cryogenic up to 500°F (260°C). The spring ensures the seal remains energized even when the jacket material contracts or expands.

Key Performance Advantages in Practice

The design of spring-energized seals translates directly into tangible performance benefits that increase reliability and reduce long-term operating costs.

Radically Low Friction

PTFE has an extremely low coefficient of friction, often compared to wet ice on wet ice. This self-lubricating property is critical in dynamic applications.

It reduces frictional heat buildup, minimizes wear on both the seal and the hardware, and lowers the energy required to operate the system.

Elimination of Compression Set

Elastomeric seals suffer from "compression set"—a permanent deformation that occurs over time under pressure and temperature, eventually causing leaks.

Because spring-energized seals rely on mechanical spring force rather than material memory, they do not take a compression set. This results in a significantly longer and more reliable service life, reducing maintenance frequency.

High-Pressure and Vacuum Capability

The constant outward force from the spring provides a tight seal even at very low pressures or under a vacuum. As system pressure increases, it further energizes the seal, enhancing its sealing capability.

This makes them exceptionally versatile for applications that experience wide pressure cycles.

Understanding the Trade-offs

While highly effective, these seals are an engineered solution, and their selection requires considering a few key factors to ensure optimal performance.

Higher Initial Cost

As precision-machined components made from advanced materials, spring-energized seals typically have a higher upfront cost than simple molded O-rings.

However, this cost is often justified by their extended lifespan, reduced downtime, and the prevention of costly failures in critical systems.

Importance of Surface Finish

Because PTFE is a harder material than most elastomers, the finish of the mating hardware surface is more critical. A smooth, properly prepared surface is essential to ensure a leak-free seal and prevent premature wear.

Spring Material and Design

The type of spring used—such as a V-spring (cantilever) or a canted coil spring—affects the seal's performance. The choice depends on the application's need for low friction versus high sealing load, and the spring material must be compatible with the system's chemical and thermal environment.

Making the Right Choice for Your Application

Selecting a spring-energized PTFE seal is a strategic decision for applications where reliability is paramount.

- If your primary focus is aggressive chemical environments: These seals are the definitive choice due to PTFE's near-universal chemical inertness.

- If your primary focus is extreme temperature cycling: Their ability to perform from cryogenic lows to high heat without degradation makes them ideal.

- If your primary focus is high-pressure or dynamic sealing: The constant force from the spring provides a reliable seal that conventional elastomers cannot match over the long term.

- If your primary focus is eliminating maintenance and downtime: Their resistance to compression set and wear provides a "fit and forget" solution for critical equipment.

Ultimately, spring-energized PTFE seals provide an engineered solution for critical applications where the failure of a standard seal is not an option.

Summary Table:

| Key Advantage | Why It Matters |

|---|---|

| Chemical Inertness | Resists virtually all acids, bases, and solvents, preventing contamination and failure. |

| Extreme Temperature Range | Performs reliably from cryogenic temperatures up to 500°F (260°C). |

| Low Friction & Self-Lubricating | Reduces wear, heat buildup, and operating energy in dynamic applications. |

| Eliminates Compression Set | Spring force ensures a constant seal, providing a longer service life than elastomers. |

| High-Pressure & Vacuum Capable | Effective across wide pressure cycles, from vacuum to high pressure. |

Need a Sealing Solution for Demanding Applications?

Spring-energized PTFE seals from KINTEK are the definitive choice for reliability in extreme environments. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision-manufactured seals ensure performance where standard seals fail.

We provide:

- Custom Fabrication: From prototypes to high-volume orders.

- Expert Material Selection: Ensuring compatibility with your specific chemical and thermal requirements.

- Precision Production: Guaranteeing a perfect fit and long-lasting performance.

Let us engineer a solution for your critical application. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining