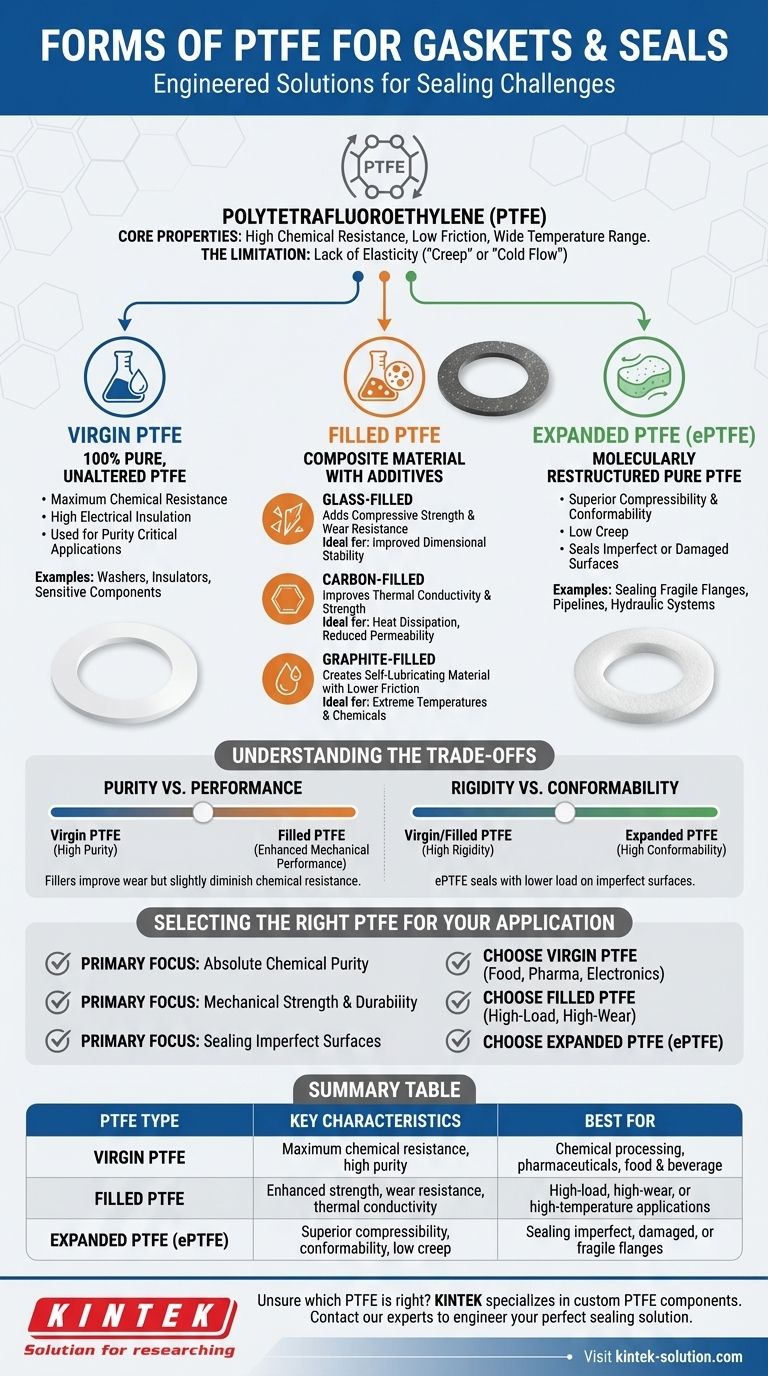

The primary forms of PTFE for gaskets and seals are virgin (pure) PTFE, filled PTFE, and expanded PTFE (ePTFE). Each form is engineered to leverage the unique properties of polytetrafluoroethylene while addressing its inherent limitations for specific sealing applications. Virgin PTFE offers maximum chemical resistance, filled PTFE enhances mechanical properties, and expanded PTFE provides superior compressibility and conformability.

Your choice between the three core types of PTFE is not a matter of which is "best," but which is precisely engineered for your specific challenge. The decision hinges on whether your application prioritizes chemical purity, mechanical strength, or the ability to seal imperfect surfaces.

Understanding PTFE's Core Properties

The Foundation of Performance

Polytetrafluoroethylene, or PTFE, is a fluoroplastic valued for several key characteristics. It is almost universally inert, resisting attack from nearly all industrial chemicals.

Its coefficient of friction is one of the lowest of any solid material, providing excellent anti-stick and low-wear properties in dynamic applications. It also maintains its integrity across a wide range of temperatures.

The Inherent Limitation

The primary drawback of standard PTFE is its lack of elasticity. Unlike rubber or other elastomers, it does not readily return to its original shape after being compressed.

This rigidity, often referred to as "creep" or "cold flow," means that in its pure form, it can struggle to maintain a long-term, resilient seal, especially under fluctuating pressures or temperatures. This single limitation is the driving force behind the development of different PTFE variants.

The Three Foundational Forms of PTFE

To overcome the material's inherent limitations and broaden its use, engineers rely on three distinct forms.

Virgin PTFE

Virgin PTFE is pure, unaltered polytetrafluoroethylene. It contains no recycled material or filler agents.

This form provides the highest chemical resistance and electrical insulation properties. It is often used for washers, insulators, and components where material purity is the most critical requirement.

Filled PTFE

Filled PTFE is a composite material where additives are blended with the base PTFE resin. These fillers are introduced to enhance specific mechanical properties that virgin PTFE lacks.

This process tailors the material for more demanding applications that require more than just chemical resistance.

Glass-Filled PTFE

Adding glass fibers significantly increases compressive strength and wear resistance. This is one of the most common fillers, ideal for applications requiring improved dimensional stability under load.

Carbon-Filled PTFE

The addition of carbon improves thermal conductivity, helping to dissipate heat away from the seal surface. It also reduces gas permeability and enhances strength.

Graphite-Filled PTFE

Graphite is often added to create a self-lubricating material with an even lower coefficient of friction than virgin PTFE. It offers excellent resistance to extreme temperatures and chemicals.

Expanded PTFE (ePTFE)

Expanded PTFE, or ePTFE, is created by molecularly restructuring the material, resulting in a soft, highly compressible, and flexible form. It is not a filled material; it is 100% pure PTFE.

This process introduces a porous, fibrous structure that retains all the chemical resistance of virgin PTFE but eliminates its structural weaknesses and tendency to creep. It is exceptionally well-suited for sealing damaged, irregular, or fragile flange joints found in pipelines and hydraulic systems.

Understanding the Trade-offs

Purity vs. Performance

The most significant trade-off is between the absolute chemical purity of virgin PTFE and the enhanced mechanical performance of filled grades.

While fillers dramatically improve wear resistance and reduce creep, they can slightly diminish the overall chemical resistance of the composite compared to the 100% pure virgin material.

Rigidity vs. Conformability

Standard PTFE gaskets, whether virgin or filled, are relatively rigid. They require significant and uniform bolt load to create an effective seal and perform best on smooth, flat, and undamaged surfaces.

Expanded PTFE solves this problem by providing a soft, conformable material that can fill in surface imperfections with much lower clamping force. However, it may not be suitable for applications requiring the high rigidity of a filled compound.

Selecting the Right PTFE for Your Application

Choosing the correct PTFE material requires a clear understanding of your primary operational goal.

- If your primary focus is absolute chemical purity and inertness: Virgin PTFE is the definitive choice for applications in food processing, pharmaceuticals, or sensitive electronics.

- If your primary focus is mechanical strength, wear resistance, or thermal management: A Filled PTFE compound tailored with glass, carbon, or graphite will provide the necessary durability.

- If your primary focus is sealing old, damaged, or fragile flanges with minimal bolt load: Expanded PTFE (ePTFE) offers the required softness and compressibility to create a reliable seal on imperfect surfaces.

Ultimately, selecting the right PTFE is about matching the material's engineered strengths directly to the demands of your specific application.

Summary Table:

| PTFE Type | Key Characteristics | Best For |

|---|---|---|

| Virgin PTFE | Maximum chemical resistance, high purity | Chemical processing, pharmaceuticals, food & beverage |

| Filled PTFE | Enhanced strength, wear resistance, thermal conductivity | High-load, high-wear, or high-temperature applications |

| Expanded PTFE (ePTFE) | Superior compressibility, conformability, low creep | Sealing imperfect, damaged, or fragile flanges |

Unsure which PTFE material is right for your seals and gaskets?

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. We help engineers in the semiconductor, medical, laboratory, and industrial sectors select the optimal material—whether virgin, filled, or expanded PTFE—to solve specific challenges like chemical resistance, mechanical strength, or sealing on imperfect surfaces.

We provide custom fabrication from prototypes to high-volume orders, ensuring your components meet exact specifications for performance and durability.

Contact our experts today for a consultation and let us help you engineer the perfect sealing solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance