In automotive engineering, PTFE seals are most commonly used in critical systems where components face high temperatures, aggressive chemicals, and high-speed rotational movement. You will find them in high-performance engines, transmissions, fuel injection pumps, steering systems, and air conditioning compressors.

The core reason for using PTFE is not just to prevent leaks, but to solve complex engineering challenges. Its unique combination of chemical inertness, temperature stability, and extremely low friction makes it the definitive choice for dynamic sealing applications where standard rubber seals would quickly fail.

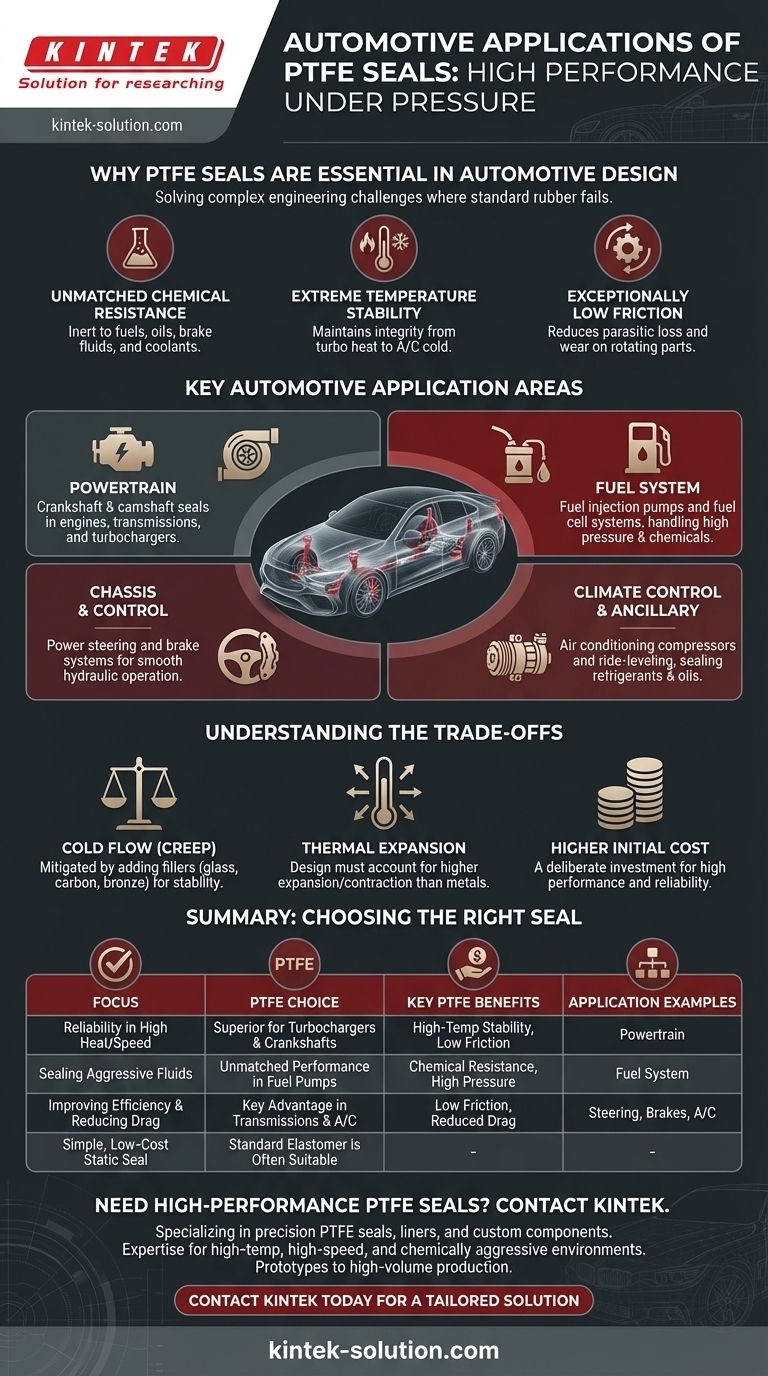

Why PTFE is a Go-To Material in Automotive Design

Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer whose properties make it uniquely suited for the demanding environments inside a modern vehicle. Understanding these properties explains its widespread use.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all automotive fluids. This includes aggressive modern fuels, synthetic oils, corrosive brake fluids, and various coolants that can degrade conventional rubber seals over time.

Extreme Temperature Stability

From the intense heat of a turbocharger to the cold of an air conditioning system, PTFE maintains its integrity and sealing capability across a very wide temperature range, preventing leaks and material failure.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This is critical for dynamic seals, which seal rotating parts like crankshafts, transmission shafts, and compressor pulleys.

This low-friction nature reduces parasitic energy loss, improves mechanical efficiency, and minimizes wear on both the seal and the shaft it contacts.

A Closer Look at Key Automotive Applications

While used in many niche areas, PTFE seals are concentrated in several key vehicle systems where performance and reliability are non-negotiable.

In the Powertrain

You'll find PTFE seals in high-performance engines, transmissions, and turbochargers. They are used as crankshaft and camshaft seals, where they must contain hot oil while enduring constant high-speed rotation.

In the Fuel System

Modern fuel systems rely on PTFE seals. They are critical in fuel injection pumps and fuel cell systems, providing a reliable seal against high-pressure, chemically complex fuels without swelling or degrading.

In Chassis and Control Systems

In power steering and brake systems, PTFE seals are used to manage high-pressure hydraulic fluids. Their low friction is essential for the smooth, responsive operation of steering racks and hydraulic actuators.

In Climate Control and Ancillary Systems

Air conditioning compressors and ride-leveling systems use PTFE seals. In A/C compressors, they effectively seal refrigerants and oils at various pressures and temperatures, all while reducing operational drag on the engine.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Engineers must consider its specific characteristics to use it correctly.

Managing Cold Flow (Creep)

Under sustained pressure, PTFE can slowly deform over time, a phenomenon known as "creep" or "cold flow." Seal manufacturers mitigate this by adding fillers like glass, carbon, or bronze to the PTFE, which significantly improves its dimensional stability.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than the metal components it's sealing. Seal design must account for this to maintain a consistent sealing force across the full operating temperature range of the vehicle.

Higher Initial Cost

PTFE seals are generally more expensive than their traditional elastomeric counterparts. Their use is a deliberate engineering decision, justified in applications where the cost of failure or the need for high performance outweighs the initial material expense.

Making the Right Choice for Your Application

Selecting the right seal material is fundamental to component longevity and system performance. The decision to use PTFE is driven by the specific demands of the application.

- If your primary focus is reliability in high-heat, high-speed environments: PTFE's thermal stability and low-friction properties make it the superior choice for components like turbochargers and engine crankshafts.

- If your primary focus is sealing against aggressive modern fluids: PTFE's chemical inertness provides unmatched long-term performance in fuel injection pumps and advanced hydraulic systems.

- If your primary focus is improving efficiency and reducing drag: The low-friction nature of PTFE is a key advantage in transmissions and A/C compressors to minimize parasitic energy loss.

- If your primary focus is a simple, low-cost static seal: A standard elastomeric seal is often a more cost-effective and perfectly suitable solution for less demanding applications.

Ultimately, choosing PTFE is an investment in durability and performance where standard materials cannot meet the challenge.

Summary Table:

| Application Area | Key PTFE Seal Benefits |

|---|---|

| Powertrain (Engine, Turbo) | High-temperature stability, low friction for high-speed shafts |

| Fuel System | Chemical resistance to modern fuels, high-pressure sealing |

| Steering & Brakes | Manages high-pressure fluids, ensures smooth operation |

| A/C Compressors | Seals refrigerants & oils, reduces drag on engine |

Need high-performance PTFE seals for your automotive components?

KINTEK specializes in manufacturing precision PTFE seals, liners, and custom components for the automotive industry. We understand the critical demands of high-temperature, high-speed, and chemically aggressive environments. Our expertise ensures your seals deliver unmatched reliability, reduce parasitic drag, and extend component life.

Whether you require prototypes or high-volume production, we provide custom fabrication to meet your exact specifications.

Contact KINTEK today to discuss your sealing challenges and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does the heat resistance of Teflon sheets benefit industrial applications? Unlock Performance Under Thermal Stress

- How do PTFE expansion bellows enhance reliability in pharmaceutical manufacturing? Ensure Purity and Uptime

- What makes PTFE washers suitable for electrical applications? Achieve Superior Insulation and Reliability

- Can PTFE machined parts be customized according to specific requirements? Achieve Precision for Demanding Applications

- How does the non-stick surface of PTFE Teflon washers contribute to their applications? Unlock Purity and Performance

- Why is dimensional stability important for PTFE rod in heavy-load applications? Prevent Failure & Ensure Reliability

- What benefits do PTFE spacer rings offer to customers? Achieve Unmatched Reliability and Lower Costs

- How does PTFE's electrical insulation property benefit electronic components? Ensure Reliability and Signal Integrity