At its core, virgin (unfilled) grade PTFE is specified for applications where extreme chemical resistance and absolute material purity are non-negotiable. It is the go-to material for high-purity seals, gaskets, medical device components, and semiconductor manufacturing parts precisely because it contains no additives.

The decision to use virgin PTFE is a deliberate choice for purity and chemical inertness over mechanical strength. Its defining softness makes it perfect for creating tight seals, but also makes it prone to deforming under load—a critical trade-off you must understand.

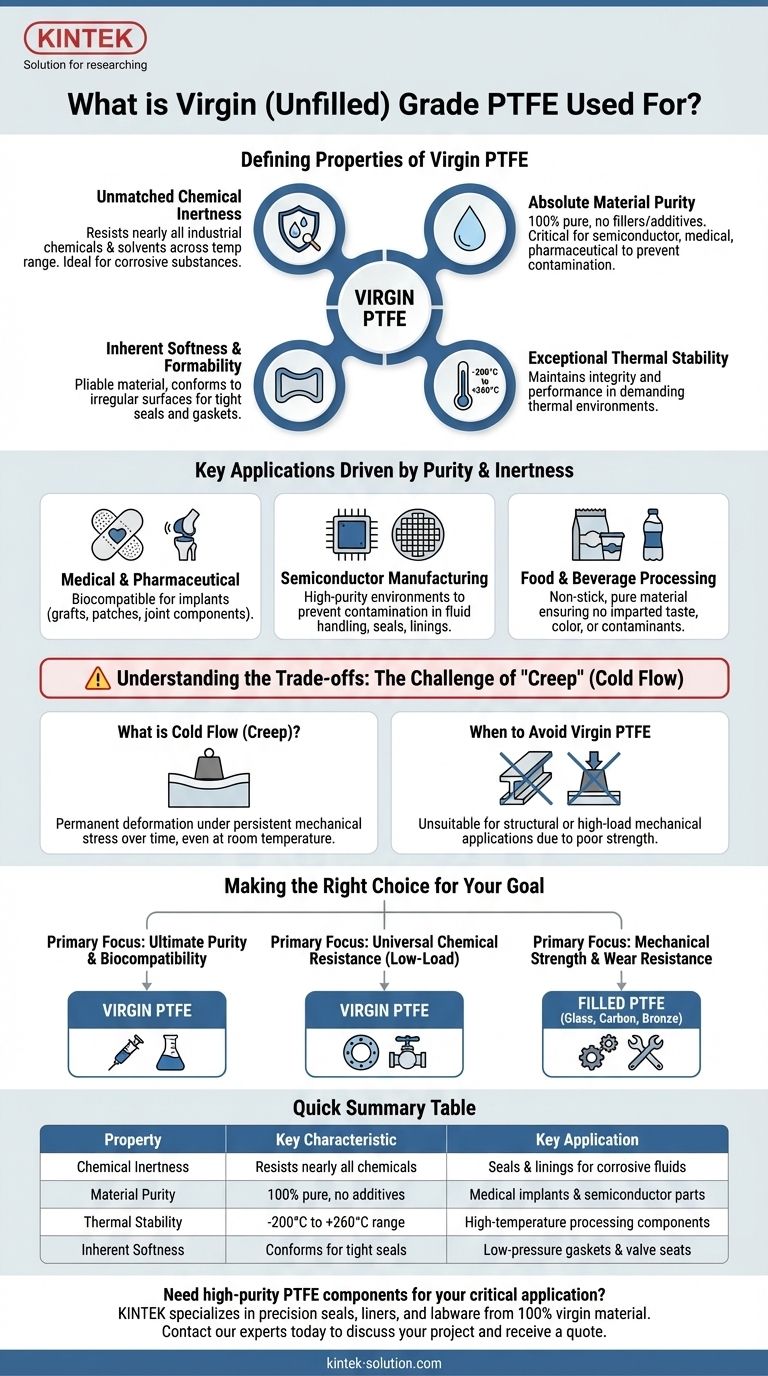

The Defining Properties of Virgin PTFE

To understand its applications, you must first understand its fundamental characteristics. Virgin PTFE is not chosen for its strength, but for its unique combination of purity, inertness, and stability.

Unmatched Chemical Inertness

Virgin PTFE is almost completely inert, resisting nearly all industrial chemicals and solvents across its entire operating temperature range. This makes it an essential material for handling highly corrosive substances.

Absolute Material Purity

As an "unfilled" material, virgin PTFE contains no fillers, plasticizers, or additives. This 100% pure composition is critical in industries like semiconductor, medical, and pharmaceutical, where any material leaching could cause catastrophic contamination.

Exceptional Thermal Stability

This material maintains its integrity across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F). It will not degrade or become brittle within this window, ensuring reliable performance in demanding thermal environments.

Inherent Softness and Formability

Virgin PTFE is an extremely soft and pliable material. This allows it to conform to irregular surfaces, making it an excellent choice for creating tight, durable seals and gaskets that prevent leaks.

Key Applications Driven by Purity and Inertness

The most critical applications for virgin PTFE leverage its purity and chemical resistance, where performance and safety cannot be compromised.

Medical and Pharmaceutical Components

Due to its biocompatibility and purity, virgin PTFE is trusted for medical implants. It is used in cardiovascular grafts, heart patches, and even as components in artificial joints where the material must not react with the body.

Semiconductor Manufacturing

In high-purity and high-heat semiconductor environments, even microscopic contamination can ruin an entire batch of microchips. Virgin PTFE is used for fluid handling components, seals, and linings because it will not leach impurities.

Food and Beverage Processing

Virgin PTFE is commonly used in food and beverage applications for its purity and non-stick properties. It ensures that the material in contact with food products does not impart any taste, color, or contaminants.

Common Industrial and Engineering Uses

Beyond high-purity sectors, virgin PTFE is a workhorse material in general engineering for its sealing and lining capabilities.

Seals, Gaskets, and Valve Seats

The softness of virgin PTFE makes it ideal for low-pressure, low-temperature chemical sealing applications. It is often used for valve seats and plugs where its ability to form a perfect seal is paramount.

Linings and Coatings

For pipes, fittings, valves, and pump parts operating in hostile environments like oil and gas, a virgin PTFE lining provides a chemically inert barrier. This protects the structural metal components from corrosion.

Understanding the Trade-offs: The Challenge of "Creep"

Trusting a material requires knowing its limitations. The primary weakness of virgin PTFE is its poor mechanical strength, specifically its tendency to "creep."

What is Cold Flow (Creep)?

Cold flow, or creep, is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress. For virgin PTFE, this means it will slowly change shape if a load is applied, even at room temperature.

When to Avoid Virgin PTFE

Because of its susceptibility to creep, virgin PTFE is unsuitable for structural components or high-load mechanical applications like bearings. If dimensional stability under pressure is required, you must look to filled PTFE grades, which add materials like glass, carbon, or bronze to improve strength and wear resistance.

Making the Right Choice for Your Goal

Selecting virgin PTFE is a specific engineering decision based on a clear set of priorities.

- If your primary focus is ultimate purity and biocompatibility: Virgin PTFE is the required choice for medical implants, pharmaceutical processing, and semiconductor components.

- If your primary focus is universal chemical resistance in a low-load environment: It is the ideal material for gaskets, seals, and linings in aggressive chemical processing systems.

- If your primary focus is mechanical strength and wear resistance: You must specify a filled or reinforced PTFE grade to prevent failure from creep under load.

Ultimately, choosing virgin PTFE means prioritizing its unparalleled purity and chemical resistance for applications where those properties are the most critical drivers of performance.

Summary Table:

| Property | Key Characteristic | Key Application |

|---|---|---|

| Chemical Inertness | Resists nearly all industrial chemicals | Seals & linings for corrosive fluids |

| Material Purity | 100% pure, no additives or fillers | Medical implants & semiconductor parts |

| Thermal Stability | Performs from -200°C to +260°C | High-temperature processing components |

| Inherent Softness | Conforms to create tight seals | Low-pressure gaskets and valve seats |

Need high-purity PTFE components for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware from 100% virgin (unfilled) material. Our expertise ensures the absolute purity and chemical resistance your medical, semiconductor, or laboratory processes demand. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What raw materials are used to create Teflon? From Simple Minerals to High-Performance PTFE

- What are some alternatives to PTFE and how do they compare? A Guide to Fluoropolymer Selection

- What does PTFE stand for? The Science Behind the Super-Material

- What are the chemical compatibility characteristics of PTFE? Unmatched Chemical Resistance for Demanding Applications

- How is Teflon used in industrial applications? Solve Extreme Heat, Chemical & Friction Challenges

- What is notable about the coefficient of friction of PTFE? Achieve Unmatched Low-Friction Performance

- How does PTFE maintain flexibility at low temperatures? Unlocking Cryogenic Performance