In an industrial context, Teflon's utility is defined by its ability to perform in extreme environments where other materials would degrade. Its applications range from chemically inert linings for pipes and vessels to low-friction coatings for machinery parts, high-performance electrical insulation for wiring, and biocompatible components for medical devices. The material’s unique combination of properties makes it a critical problem-solver across dozens of sectors.

The industrial value of Teflon (PTFE) isn't based on a single feature, but on its rare combination of properties: extreme chemical inertness, a remarkably low coefficient of friction, and high-temperature stability. This synergy makes it an indispensable material in environments that demand performance without failure.

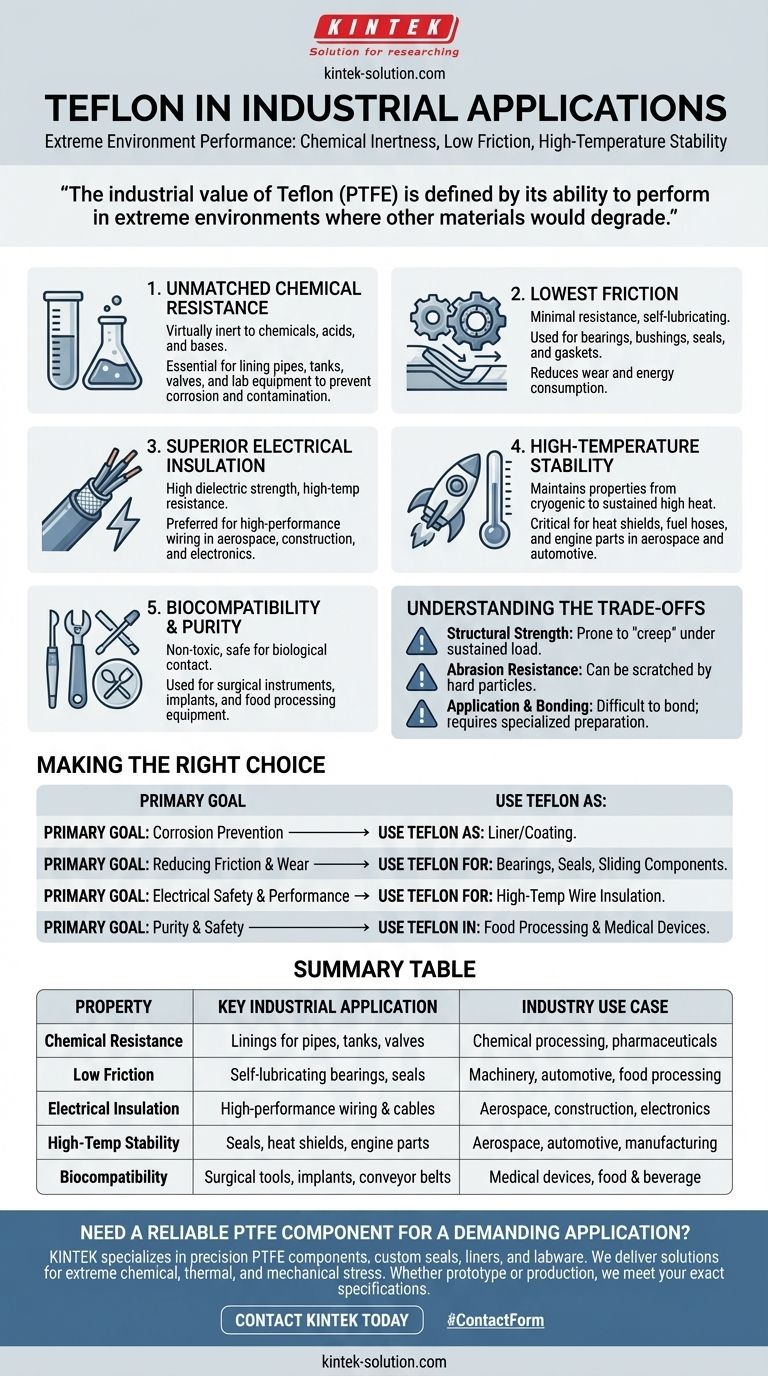

Why Teflon is a Go-To Industrial Material

Teflon, a brand name for Polytetrafluoroethylene (PTFE), is rarely chosen as a general-purpose plastic. It is a specialty polymer selected when operational conditions involving heat, chemical exposure, or friction are too severe for conventional materials.

Unmatched Chemical Resistance

Teflon is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases.

This property makes it essential for lining pipes, tanks, valves, and laboratory equipment. In the chemical and steel processing industries, this prevents both corrosion of the equipment and contamination of the product.

The Lowest Friction of Any Solid

Teflon has one of the lowest coefficients of friction known, meaning surfaces can slide against each other with minimal resistance.

This is leveraged in machinery for self-lubricating bearings, bushings, seals, and gaskets. It reduces wear and energy consumption in applications where wet lubricants like oil or grease are impractical or would cause contamination.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with a high dielectric strength and resistance to high temperatures.

This makes it a preferred material for insulating high-performance wiring and cables, especially in aerospace and construction. Its resistance to water, flame, and chemicals further protects the integrity of electrical systems in harsh conditions.

High-Temperature Stability

Teflon can maintain its properties across a wide range of temperatures, from cryogenic levels up to sustained high-heat environments.

This stability is critical in aerospace for components like heat shields, fuel hoses, and nose cones. In automotive applications, it is used for seals and parts that must endure engine heat.

Biocompatibility and Purity

The material is non-toxic and does not support microbial growth, making it safe for contact with biological materials and food.

This has led to its widespread use in the medical field for surgical instruments, implants like artificial bones, and even heart valves. In food processing, it is used for non-stick conveyor belts, liners, and seals to ensure a clean and efficient production line.

Understanding the Trade-offs

While Teflon's properties are exceptional, it is not a universally perfect material. Understanding its limitations is key to using it effectively.

Structural Strength

Teflon is a relatively soft material compared to metals or engineering plastics. It can be prone to "creep," or deforming slowly over time when under a sustained load, making it unsuitable for high-load structural components.

Abrasion Resistance

While Teflon's low friction helps it resist wear from smooth, sliding contact, it can be easily scratched or damaged by hard, abrasive particles. It is not an ideal choice for environments with significant grit or particulate contamination.

Application and Bonding

The same non-stick property that makes Teflon valuable also makes it very difficult to bond to other materials. Applying Teflon coatings or bonding it to substrates requires specialized surface preparation and application processes.

Making the Right Choice for Your Goal

Choosing Teflon requires aligning its unique properties with your primary operational challenge.

- If your primary focus is corrosion prevention: Use Teflon as a liner or coating for pipes, valves, and vessels handling aggressive chemicals.

- If your primary focus is reducing friction and wear: Specify Teflon for bearings, seals, and sliding components, especially in applications where liquid lubricants are not viable.

- If your primary focus is electrical safety and performance: Use Teflon for high-temperature wire insulation where signal integrity and reliability are paramount.

- If your primary focus is purity and safety: Employ Teflon in food processing equipment and medical devices due to its inertness and biocompatibility.

Ultimately, Teflon is chosen not as a general-purpose material, but as a specialized solution for the most demanding industrial environments.

Summary Table:

| Property | Key Industrial Application | Industry Use Case |

|---|---|---|

| Chemical Resistance | Linings for pipes, tanks, valves | Chemical processing, pharmaceuticals |

| Low Friction | Self-lubricating bearings, seals | Machinery, automotive, food processing |

| Electrical Insulation | High-performance wiring & cables | Aerospace, construction, electronics |

| High-Temp Stability | Seals, heat shields, engine parts | Aerospace, automotive, manufacturing |

| Biocompatibility | Surgical tools, implants, conveyor belts | Medical devices, food & beverage |

Need a reliable PTFE component for a demanding application?

KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine expert material knowledge with advanced fabrication capabilities to deliver solutions that withstand extreme chemical, thermal, and mechanical stress.

Whether you require a prototype or a high-volume production run, we ensure your components meet exact specifications for performance and durability.

Contact KINTEK today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key components of PTFE? Unlocking the Power of Carbon and Fluorine

- What temperature range can Teflon plastic sheets withstand? Unlocking Performance from -200°C to +260°C

- What is Polytetrafluoroethylene (PTFE) and what are its main types? Unlock High-Performance Solutions

- What future advancements are expected in the recycling and reusability of PTFE? Discover New Chemical & Mechanical Breakthroughs

- What is the chemical compatibility of PTFE? The Ultimate Guide to Chemical Resistance

- In what medical devices is PTFE commonly used? Essential Components for Safety and Reliability

- What makes Teflon a valuable ingredient in personal care product formulations? Enhance Performance with Unique Properties

- How is PTFE applied in hydrogen energy applications? Ensuring Safety and Efficiency in H2 Systems