For practical purposes, PTFE is chemically inert. It is highly resistant to nearly all chemicals and solvents, holding this property up to its maximum continuous operating temperature of 500°F (260°C). The only known exceptions are a few extremely reactive substances, namely molten alkali metals, elemental fluorine, and certain fluorochemicals like chlorine trifluoride (ClF3).

The core principle to understand is that PTFE's chemical resistance is nearly absolute, making it a default choice for demanding applications. Its rare failures only occur under extreme and specific chemical conditions that most applications will never encounter.

The Foundation of PTFE's Chemical Resistance

Polytetrafluoroethylene (PTFE) is renowned for its non-reactivity, which is why it is specified for use in aggressive chemical environments, from laboratories to heavy industry.

A Profile in Broad Compatibility

PTFE shows excellent compatibility across a vast range of chemical families. It does not react with common or aggressive agents.

This includes strong acids (hydrochloric, sulfuric), bases, alcohols, ketones, hydrocarbons, and esters. Its reliability extends to industrial chemicals like ammonia and hydrogen peroxide as well as petroleum products.

The Role of Temperature

The material's chemical inertness is maintained up to its maximum continuous operating temperature of 500°F (260°C).

Beyond this temperature, the material properties begin to degrade, but its fundamental chemical resistance remains exceptional within this operating window.

Understanding the Trade-offs: The Critical Exceptions

While its compatibility list is extensive, its few incompatibilities are severe. Understanding these limitations is critical for safe and effective material selection in extreme applications.

Molten Alkali Metals

PTFE will be attacked by molten alkali metals, such as sodium or potassium. This is a highly specific condition that is not common in most industrial processes.

Elemental Fluorine

Pure fluorine, particularly in a turbulent liquid or gaseous state, is one of the few elements that can chemically attack PTFE.

Potent Fluorinating Agents

Certain powerful fluorochemicals can also compromise PTFE's integrity, especially at elevated temperatures.

These compounds, such as chlorine trifluoride (ClF3) and oxygen difluoride (OF2), work by liberating free fluorine, which then attacks the PTFE structure.

How to Apply This to Your Project

Your decision to use PTFE should be based on a clear understanding of your specific chemical environment.

- If your primary focus is handling common solvents, acids, or bases: PTFE is an exceptionally safe and reliable choice, provided you operate below its 500°F (260°C) temperature limit.

- If your primary focus is an extreme chemical process: You must verify that your environment does not involve molten alkali metals, elemental fluorine, or potent fluorinating agents like ClF3.

- If you require absolute certainty for a specific concentration: Always consult a detailed chemical compatibility chart or your material supplier to confirm suitability for your exact parameters.

By respecting its well-defined limitations, you can confidently leverage PTFE's remarkable chemical inertness for your most demanding applications.

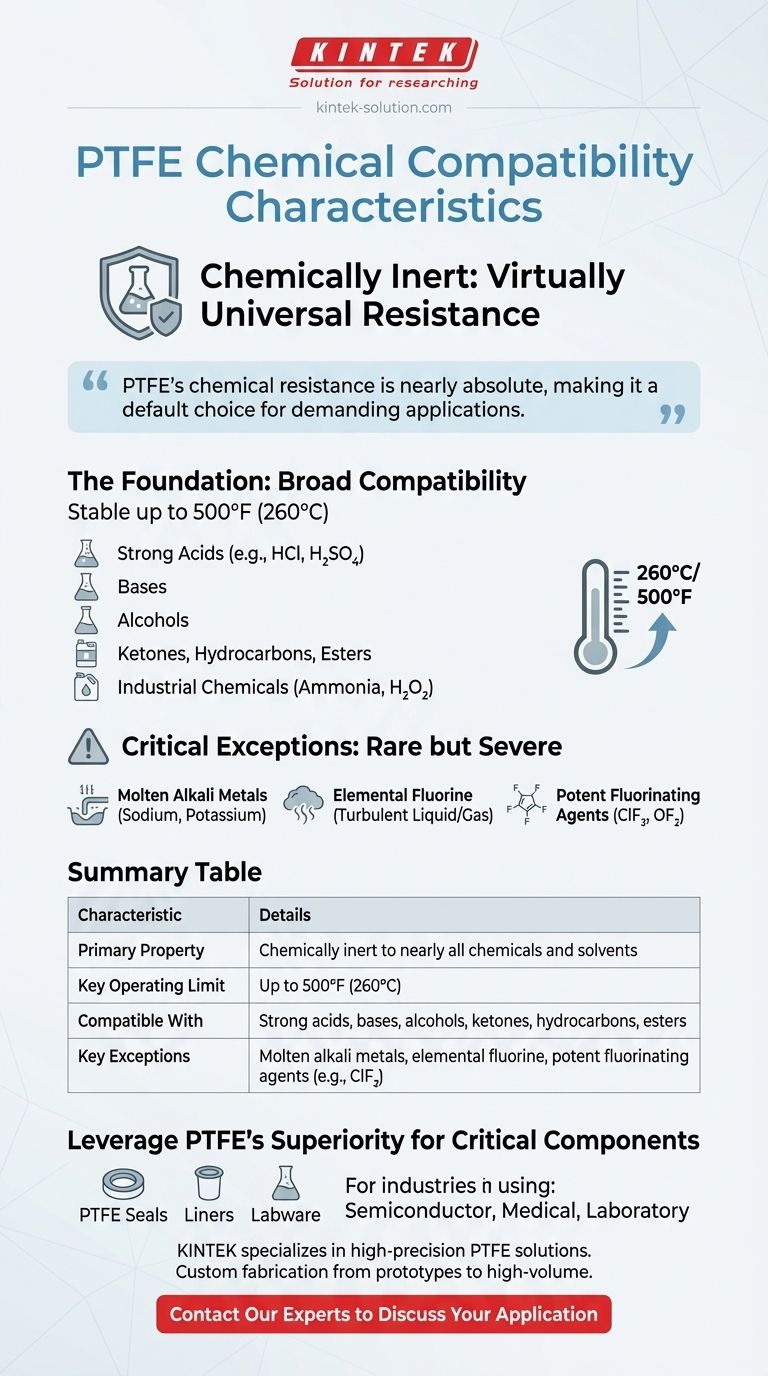

Summary Table:

| Characteristic | Details |

|---|---|

| Primary Property | Chemically inert to nearly all chemicals and solvents |

| Key Operating Limit | Up to 500°F (260°C) |

| Compatible With | Strong acids, bases, alcohols, ketones, hydrocarbons, esters |

| Key Exceptions | Molten alkali metals, elemental fluorine, potent fluorinating agents (e.g., ClF3) |

Leverage PTFE's superior chemical resistance for your critical components. KINTEK specializes in manufacturing high-precision PTFE seals, liners, and labware for the semiconductor, medical, and laboratory industries. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications. Contact our experts today to discuss how our PTFE solutions can enhance the reliability and performance of your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications