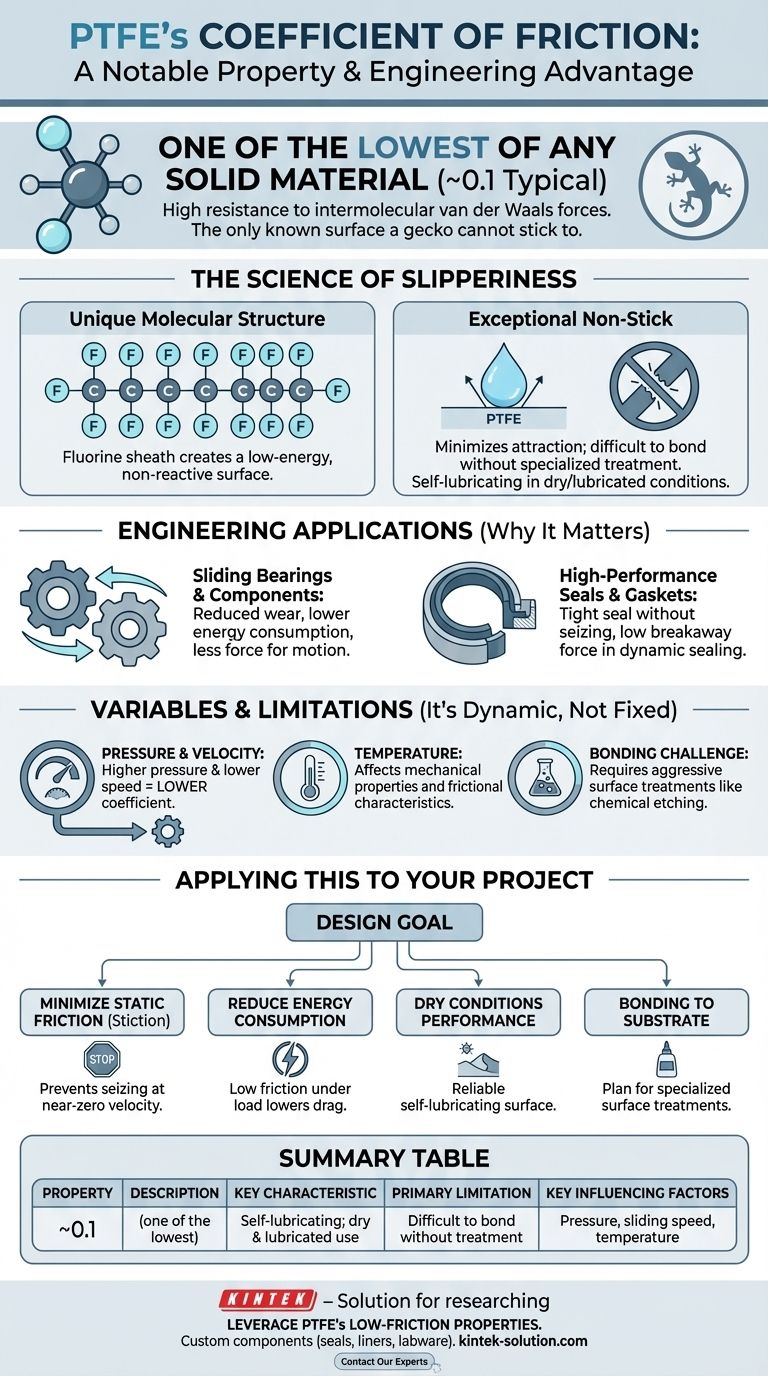

What is notable about the coefficient of friction of PTFE is that it is one of the lowest of any known solid material. This gives Polytetrafluoroethylene (PTFE) its famously "slippery" or non-stick quality, with a typical coefficient value around 0.1. This property is so pronounced because PTFE is highly resistant to intermolecular van der Waals forces, making it the only known surface a gecko cannot stick to.

The core takeaway is that while PTFE's coefficient of friction is exceptionally low, it is not a fixed constant. Its true value in any application is dynamic, influenced by operational factors such as pressure, sliding speed, and temperature.

The Source of PTFE's "Slipperiness"

PTFE's unique friction characteristics stem directly from its molecular structure and the resulting surface energy.

A Unique Molecular Structure

The polymer consists of a long chain of carbon atoms completely sheathed by fluorine atoms. This fluorine sheath creates an incredibly low-energy, non-reactive surface, minimizing the forces of attraction between PTFE and any other material touching it.

Exceptional Resistance to Adhesion

This low surface energy makes it nearly impossible for other materials to "grip" it. This is why it's used for non-stick coatings and is notoriously difficult to bond using conventional adhesives without specialized surface preparation.

Performance Without Lubrication

Unlike many materials that require oil or grease, PTFE performs exceptionally well in both dry and lubricated conditions. Its inherent properties provide a self-lubricating effect, making it ideal for clean environments or applications where external lubrication is impractical.

Why This Matters in Engineering Applications

This single property makes PTFE a critical problem-solver in a wide range of mechanical and industrial scenarios.

Sliding Bearings and Components

For sliding parts, bearings, and bushings, PTFE's low friction directly translates to reduced wear and lower energy consumption. Less force is required to initiate and sustain motion, which improves efficiency.

High-Performance Seals and Gaskets

In sealing applications, the low friction allows for a tight seal without the risk of seizing or requiring a high breakaway force. This is critical in dynamic seals that must move while preventing leaks.

Understanding the Variables and Limitations

Relying on a single textbook value for PTFE's friction is a common oversight. Its performance is nuanced.

It's Not a Single Number

The widely cited coefficient of 0.1 is a useful guideline, but it changes based on the operating environment.

The Impact of Pressure and Velocity

The coefficient of friction for PTFE is dependent on load and speed. Generally, higher pressures and lower sliding velocities result in a lower coefficient of friction. This is a critical consideration for component design.

The Influence of Temperature

As with most polymers, temperature can also alter the mechanical properties of PTFE, which in turn affects its frictional characteristics.

The Challenge of Bonding

The primary trade-off for low friction is difficulty in adhesion. Its non-stick nature is a significant engineering hurdle if the PTFE component needs to be glued or bonded to another substrate. This typically requires aggressive surface treatments like chemical etching.

Applying This to Your Project

Your design goal will determine how you leverage PTFE's unique frictional properties.

- If your primary focus is minimizing static friction (stiction): PTFE is an excellent choice, as its low coefficient at near-zero velocities prevents components from seizing.

- If your primary focus is reducing energy consumption: PTFE's consistently low friction under load significantly lowers the energy needed to overcome drag in moving systems.

- If your primary focus is a component that must perform in dry conditions: PTFE provides a reliable self-lubricating surface that maintains performance where other materials would fail.

- If you need to bond the material to a substrate: You must plan for specialized surface treatments, as standard adhesives will fail on untreated PTFE.

Understanding these factors allows you to leverage PTFE's remarkable low-friction properties effectively for your specific engineering challenge.

Summary Table:

| Property | Description |

|---|---|

| Typical Coefficient of Friction | ~0.1 (one of the lowest for any solid) |

| Key Characteristic | Self-lubricating; performs well in dry and lubricated conditions |

| Primary Limitation | Difficult to bond without specialized surface treatment |

| Key Influencing Factors | Pressure, sliding speed, temperature |

Leverage PTFE's exceptional low-friction properties for your project. KINTEK specializes in the precision manufacturing of custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. From prototypes to high-volume orders, we deliver the reliability and performance your application demands. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability