PTFE gland packing is a high-performance sealant used to create a fluid-tight seal around the moving shafts or stems of industrial equipment like pumps and valves. It is most commonly known as Teflon gland packing, as PTFE (polytetrafluoroethylene) is the generic chemical name for the brand name Teflon.

The core value of PTFE, or Teflon, gland packing lies in its unique combination of chemical inertness and an extremely low coefficient of friction. This makes it an essential sealing solution for applications involving aggressive chemicals or high-speed equipment, where it protects machinery from both corrosion and wear.

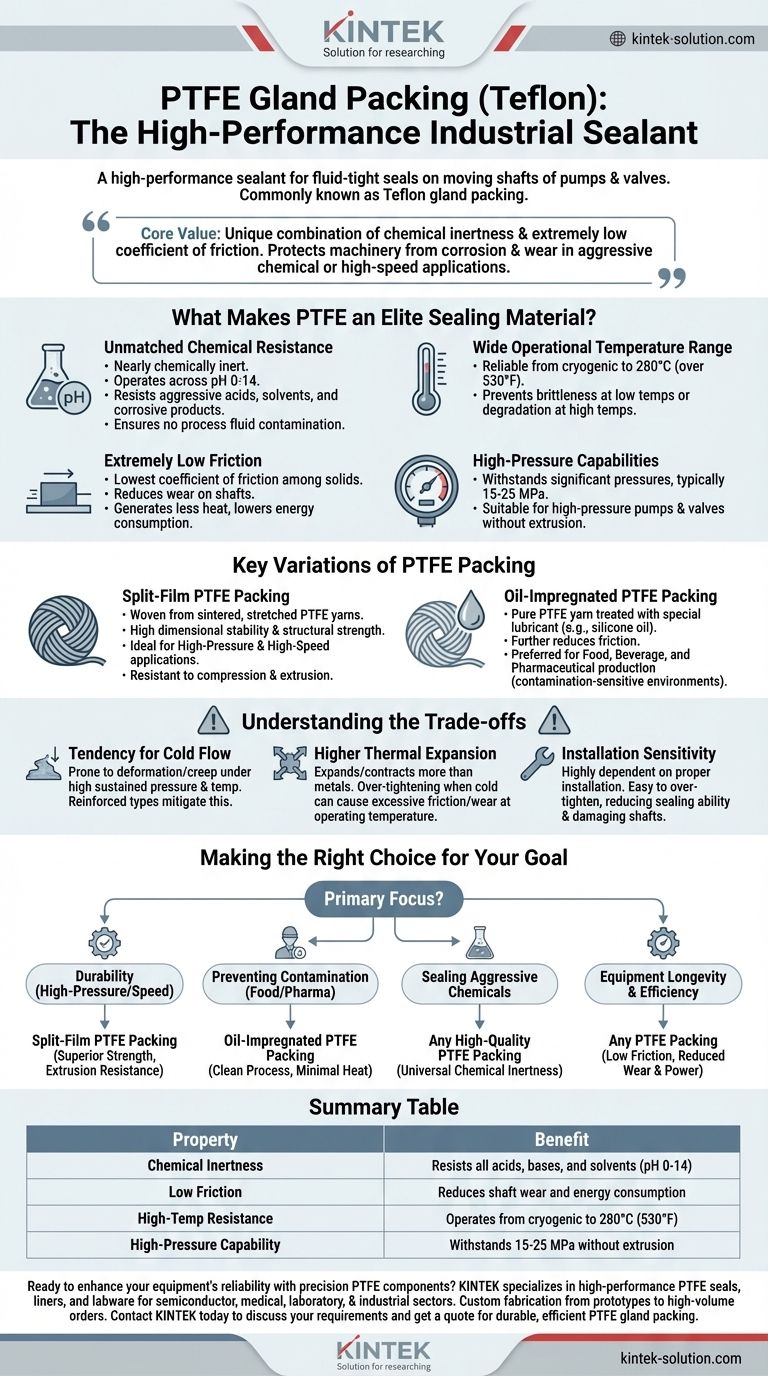

What Makes PTFE an Elite Sealing Material?

The properties of PTFE make it exceptionally well-suited for demanding industrial sealing applications where other materials would quickly fail. Its performance stems from its unique molecular structure.

Unmatched Chemical Resistance

PTFE is nearly chemically inert, meaning it does not react with most substances. It can operate across the entire pH scale (0-14), withstanding aggressive acids, solvents, and other corrosive products.

This level of resistance ensures the packing maintains its integrity and does not contaminate the process fluid, which is critical in industries like chemical processing and pharmaceuticals.

Wide Operational Temperature Range

PTFE packing performs reliably across an exceptional range of temperatures, from cryogenic conditions up to 280°C (over 530°F). This stability prevents the seal from becoming brittle at low temperatures or degrading at high temperatures.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This "slipperiness" significantly reduces wear on the moving pump shaft or valve stem it seals against.

Lower friction also means less heat is generated during operation, reducing the risk of overheating and lowering the energy required to run the equipment.

High-Pressure Capabilities

Engineered PTFE packings are designed to withstand significant pressures, typically in the range of 15 to 25 MPa. This makes them suitable for sealing high-pressure pumps and valves without being extruded or forced out of place.

Key Variations of PTFE Packing

Not all PTFE packing is the same. The construction is adapted to optimize performance for specific conditions, with two common variations being split-film and oil-impregnated.

Split-Film PTFE Packing

This type is woven from sintered, fully stretched PTFE yarns. The process creates a packing with high dimensional stability and structural strength.

It is particularly resistant to compression and extrusion, making it ideal for high-pressure and high-speed applications where durability is paramount.

Oil-Impregnated PTFE Packing

This variant is made from pure PTFE yarn that has been treated with a special lubricant, typically silicone oil. The oil further reduces the already low friction coefficient.

It is designed for high peripheral speeds where heat buildup is a concern and is the preferred choice for industries where contamination is unacceptable, such as food, beverage, and pharmaceutical production.

Understanding the Trade-offs

While PTFE is a superior material, no solution is without its considerations. Understanding its limitations is key to successful implementation.

Tendency for Cold Flow

Under high, sustained pressure and temperature, pure PTFE can be prone to "cold flow," a phenomenon where the material slowly deforms or creeps. Reinforced packings like split-film are specifically designed to mitigate this.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than metals do. This must be accounted for during installation; a packing that is over-tightened when cold may create excessive friction and wear once the equipment reaches operating temperature.

Installation Sensitivity

The effectiveness of any gland packing is highly dependent on proper installation. Due to its low friction, it can be easy to over-tighten PTFE packing, which crushes the material, reduces its sealing ability, and can damage the shaft.

Making the Right Choice for Your Goal

Selecting the correct packing requires matching the material's properties to the specific demands of your equipment and process.

- If your primary focus is durability in high-pressure, high-speed pumps: Choose a split-film PTFE packing for its superior structural strength and resistance to extrusion.

- If your primary focus is preventing contamination in food or pharmaceutical applications: Opt for an oil-impregnated PTFE packing to ensure a clean process and minimal heat generation.

- If your primary focus is sealing against highly aggressive or corrosive chemicals: Any high-quality PTFE packing is an excellent choice due to its nearly universal chemical inertness.

- If your primary focus is equipment longevity and energy efficiency: The inherently low friction of all PTFE packings will reduce wear on shafts and lower overall power consumption.

By understanding these distinctions, you can select a sealant that not only prevents leaks but also enhances the long-term reliability and efficiency of your system.

Summary Table:

| Property | Benefit |

|---|---|

| Chemical Inertness | Resists all acids, bases, and solvents (pH 0-14) |

| Low Friction | Reduces shaft wear and energy consumption |

| High-Temp Resistance | Operates from cryogenic to 280°C (530°F) |

| High-Pressure Capability | Withstands 15-25 MPa without extrusion |

Ready to enhance your equipment's reliability with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution perfectly matched to your application's demands, whether it's for aggressive chemicals, high speeds, or ultra-clean environments.

Contact KINTEB today to discuss your specific requirements and get a quote for durable, efficient PTFE gland packing.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How do PTFE components compare to metal components? Choose the Right Material for Your Application

- How does a PTFE Lined Butterfly Valve operate? A Guide to Corrosive Flow Control

- How should the right PTFE washer thickness be selected? Balance Sealing, Creep, and Pressure

- How do PTFE balls perform against various chemicals? Unmatched Chemical Resistance for Harsh Environments

- What is the conclusion regarding PTFE bellows as a material choice? Prioritize Chemical Inertness and Flexibility

- What are the symptoms of a leaking PTFE butterfly valve? Identify External & Internal Leaks

- In which automotive applications are PTFE rubber seals used? Essential for High-Performance and EV Systems

- In which industries are PTFE gland packings commonly used? For Purity, Chemical Resistance & Reliability