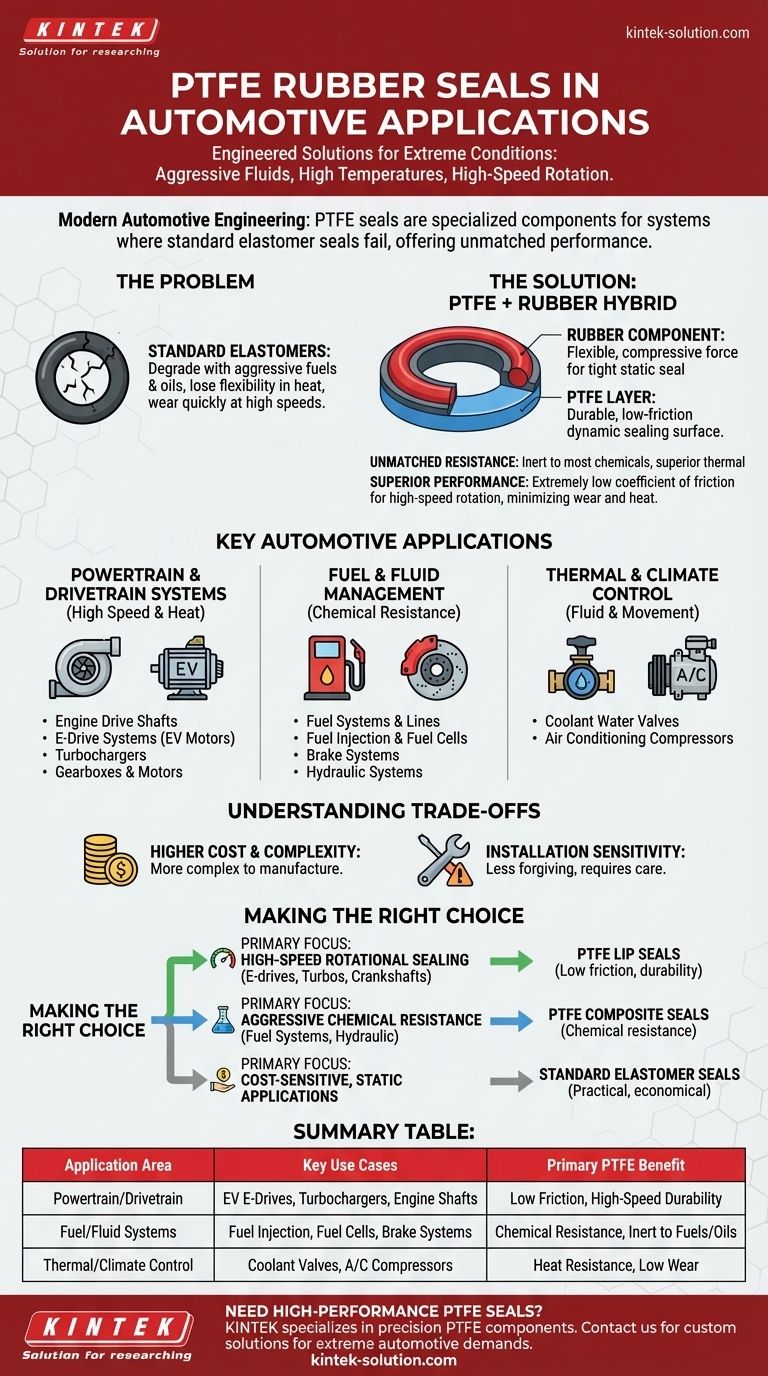

In modern automotive engineering, Polytetrafluoroethylene (PTFE) rubber seals are specialized components deployed in systems where standard elastomer seals would fail. They are primarily used to handle aggressive fluids, extreme temperatures, and high-speed rotating components found in applications like fuel systems, electric vehicle (EV) e-drives, high-performance engines, and cooling systems.

PTFE seals are not a general-purpose replacement for rubber. They are a targeted engineering solution for automotive applications where the combined challenges of chemical exposure, high temperatures, and high rotational speeds exceed the capabilities of conventional materials.

Why PTFE is Essential in Demanding Automotive Systems

To understand where these seals are used, it's crucial to understand the problems they solve. Standard rubber seals can degrade, swell, or fail when exposed to harsh conditions.

The Problem with Standard Elastomers

Standard rubber, or elastomer, seals are excellent for many applications but have distinct limits. They can break down when exposed to aggressive fuels and oils, lose their flexibility at extreme temperatures, and wear out quickly under the friction of high-speed rotation.

Unmatched Chemical and Thermal Resistance

PTFE is virtually inert to most chemicals, making it ideal for direct contact with modern fuels, oils, and additives. This is why PTFE seals are critical components in fuel injection pumps, fuel cell systems, and other core parts of the vehicle's fluid management architecture.

Superior Performance for High-Speed Rotation

One of PTFE's most valued properties is its extremely low coefficient of friction. This allows PTFE lip seals to handle high-speed rotating shafts with minimal wear and heat generation.

This makes them essential for performance-critical components like NASCAR engine drive shafts, turbochargers, and the high-RPM shafts found in EV e-drive systems.

The Hybrid Advantage: PTFE + Rubber

Many of these components are composite seals. A rubber element, typically an O-ring, provides the flexible, compressive force needed for a tight static seal. A bonded PTFE layer then provides the durable, low-friction dynamic sealing surface that contacts the moving part.

This hybrid design delivers the best of both worlds: the robust sealing pressure of rubber and the durability of PTFE.

A Breakdown of Key Automotive Applications

Based on its unique properties, PTFE finds its way into several specific, high-stress automotive systems.

Powertrain and Drivetrain Systems

These applications involve high rotational speeds and significant heat.

- Engine Drive Shafts: Particularly in high-performance and racing engines.

- E-Drive Systems: Sealing the high-speed electric motors in EVs.

- Turbochargers: Enduring extreme temperatures and rotational speeds.

- Gearboxes and Motors: Protecting bearings and internal components.

Fuel and Fluid Management

This is where PTFE's chemical resistance is paramount.

- Fuel Systems: Including seals for fuel lines and pumps.

- Fuel Injection and Fuel Cells: Preventing leaks of volatile or corrosive fluids.

- Brake Systems: Withstanding the specific chemical makeup of brake fluid.

- Hydraulic Systems: Used in actuators and pumps for steering and other functions.

Thermal and Climate Control

These systems involve both fluid management and dynamic movement.

- Coolant Water Valves: PTFE provides a low-friction surface for the rotating valve while the rubber ensures a tight seal.

- Air Conditioning Compressors: Sealing the compressor shaft against refrigerant and oil.

Understanding the Trade-offs

While highly effective, PTFE seals are a specialized solution, not a universal one. Understanding their limitations is key to using them correctly.

Higher Cost and Complexity

PTFE seals, especially composite designs, are more complex and expensive to manufacture than simple elastomer O-rings. Their use is only justified where performance requirements make standard seals inadequate.

Installation Sensitivity

The relative stiffness of a PTFE lip means these seals can be less forgiving during installation than a highly flexible rubber seal. Care must be taken to avoid scratching or damaging the sealing lip, which could compromise its performance.

Not a Default Choice

For thousands of low-speed, static, or less chemically aggressive applications in a vehicle, a standard elastomer seal remains the most practical and cost-effective choice. PTFE is reserved for the true problem areas.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching the material's capabilities to the system's specific operational demands.

- If your primary focus is high-speed rotational sealing: PTFE lip seals are the definitive choice for applications like e-drives, turbochargers, and high-performance crankshafts where friction and heat are major concerns.

- If your primary focus is aggressive chemical resistance: PTFE composite seals are critical for modern fuel systems, fuel cells, and hydraulic components exposed to fluids that degrade standard elastomers.

- If your primary focus is cost-sensitive, static applications: A standard elastomer seal is almost always the more practical and economical solution for components without extreme speed or chemical exposure.

Ultimately, choosing the correct seal is about matching the material's unique capabilities to the specific engineering challenges of the automotive system.

Summary Table:

| Application Area | Key Use Cases | Primary PTFE Benefit |

|---|---|---|

| Powertrain/Drivetrain | EV E-Drives, Turbochargers, Engine Shafts | Low Friction, High-Speed Durability |

| Fuel/Fluid Systems | Fuel Injection, Fuel Cells, Brake Systems | Chemical Resistance, Inert to Fuels/Oils |

| Thermal/Climate Control | Coolant Valves, A/C Compressors | Heat Resistance, Low Wear |

Need high-performance PTFE seals for your automotive application? KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your automotive systems meet extreme demands for chemical resistance, temperature stability, and high-speed operation. Contact us today to discuss your project and leverage our expertise in advanced material solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts