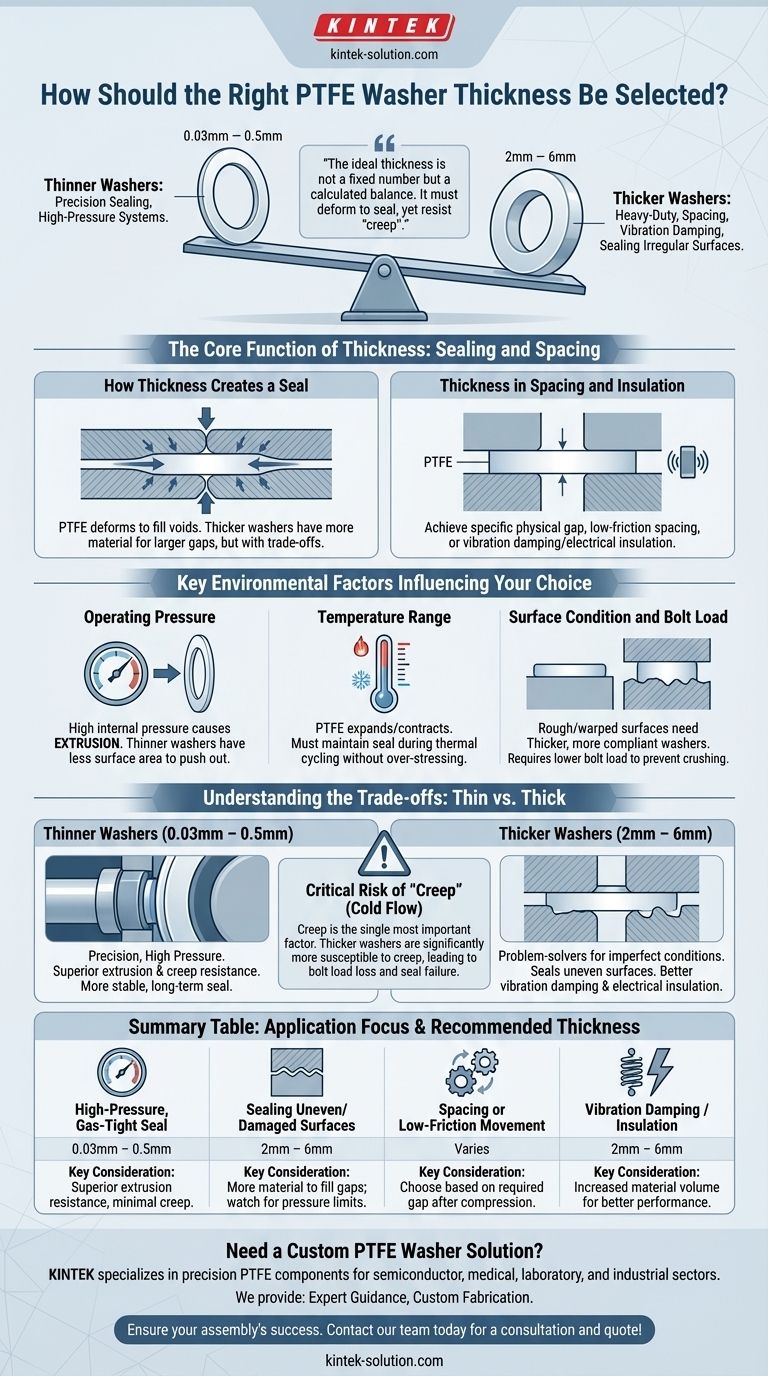

Selecting the right PTFE washer thickness is a critical engineering decision that directly impacts the performance and reliability of an assembly. Generally, thinner washers (0.03mm – 0.5mm) are used for precision sealing in high-pressure systems, while thicker washers (2mm – 6mm) are reserved for heavy-duty applications like spacing, vibration damping, or sealing irregular surfaces.

The ideal PTFE washer thickness is not a fixed number but a calculated balance. It must be thick enough to deform and create a reliable seal under a specific load, yet thin enough to resist "creep"—the tendency of the material to flow out of the joint over time.

The Core Function of Thickness: Sealing and Spacing

To choose the right thickness, you must first define the washer's primary job. Is it meant to create a leak-proof seal, maintain a precise gap, or absorb vibration? The answer dictates the optimal thickness.

How Thickness Creates a Seal

PTFE is a relatively soft material. When compressed between two surfaces (like pipe flanges), the washer's thickness provides the necessary volume of material to deform and flow into microscopic imperfections. This action creates an intimate, leak-proof barrier.

A thicker washer has more material to fill larger gaps or surface irregularities. However, this comes with significant trade-offs.

Thickness in Spacing and Insulation

In non-sealing applications, the washer may act as a low-friction spacer, a vibration damper, or an electrical insulator.

In these cases, thickness is chosen primarily to achieve a specific physical gap or desired level of insulation, while still considering the compressive load it will endure.

Key Environmental Factors Influencing Your Choice

The operating environment places unique demands on the washer, and thickness is a key variable in withstanding those demands.

Operating Pressure

High internal pressure is the primary force trying to push the washer material out of the joint. This phenomenon is known as extrusion.

A thinner washer presents a smaller surface area to this internal pressure, making it inherently more resistant to being pushed out of place. This is why high-pressure applications often favor thinner, more robust seals.

Temperature Range

PTFE expands and contracts with temperature changes. A washer must be thick enough to maintain a sealing force during thermal cycling without becoming loose or over-stressed.

Extreme heat can soften PTFE, making it more susceptible to creep, while extreme cold can make it harder and less able to conform to surfaces.

Surface Condition and Bolt Load

The condition of the mating surfaces is critical. Rough, warped, or damaged flanges require a thicker, more compliant washer to effectively fill the voids and create a seal.

However, this often requires a lower bolt load. A thick washer under excessive bolt load can easily be crushed or extruded from the joint.

Understanding the Trade-offs: Thin vs. Thick

There is no universally "better" option; the choice between a thin and thick washer is a matter of engineering trade-offs based on the application's specific needs.

The Case for Thinner Washers (0.03mm – 0.5mm)

Thinner washers are the default choice for precision applications, especially those involving high pressure.

They offer superior resistance to extrusion and creep because there is simply less material to displace. This results in a more stable, reliable, long-term seal.

The Case for Thicker Washers (2mm – 6mm)

Thicker washers are essentially problem-solvers for imperfect conditions.

Their primary advantage is the ability to seal uneven surfaces. They also provide better vibration damping and electrical insulation due to their increased material volume.

The Critical Risk of 'Creep' (Cold Flow)

Creep is the single most important factor to consider with PTFE. Under sustained compressive load, the material will slowly deform and "flow" away from the pressure point.

Thicker washers are significantly more susceptible to creep. If the washer creeps too much, the bolt load will decrease, and the seal will eventually fail. This is the primary reason to use the thinnest washer that can get the job done.

Making the Right Choice for Your Application

Use these guidelines to select a thickness based on your primary objective.

- If your primary focus is a high-pressure, gas-tight seal: Opt for the thinnest washer possible that can accommodate the surface finish of your components.

- If your primary focus is sealing uneven or damaged surfaces: A thicker washer provides more material to fill gaps, but be sure to operate well within its pressure limits to avoid creep.

- If your primary focus is spacing or low-friction movement: Select thickness based on the required gap, accounting for any compression that will occur under load.

- If your primary focus is vibration damping or electrical insulation: A thicker washer is generally superior, providing more material to absorb energy or resist electrical current.

Ultimately, choosing the correct washer thickness is fundamental to designing a joint that performs with stability and longevity.

Summary Table:

| Application Focus | Recommended Thickness Range | Key Consideration |

|---|---|---|

| High-Pressure, Gas-Tight Seal | 0.03mm – 0.5mm | Superior extrusion resistance, minimal creep. |

| Sealing Uneven/Damaged Surfaces | 2mm – 6mm | More material to fill gaps; watch for pressure limits. |

| Spacing or Low-Friction Movement | Varies | Choose based on required gap after compression. |

| Vibration Damping / Insulation | 2mm – 6mm | Increased material volume for better performance. |

Need a Custom PTFE Washer Solution?

Choosing the right thickness is critical for performance and safety. KINTEK specializes in manufacturing precision PTFE components, including custom washers, for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Guidance: Our engineers can help you select the ideal thickness and material for your specific pressure, temperature, and surface conditions.

- Custom Fabrication: From prototypes to high-volume orders, we deliver washers that meet your exact specifications for reliability and longevity.

Ensure your assembly's success. Contact our team today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments