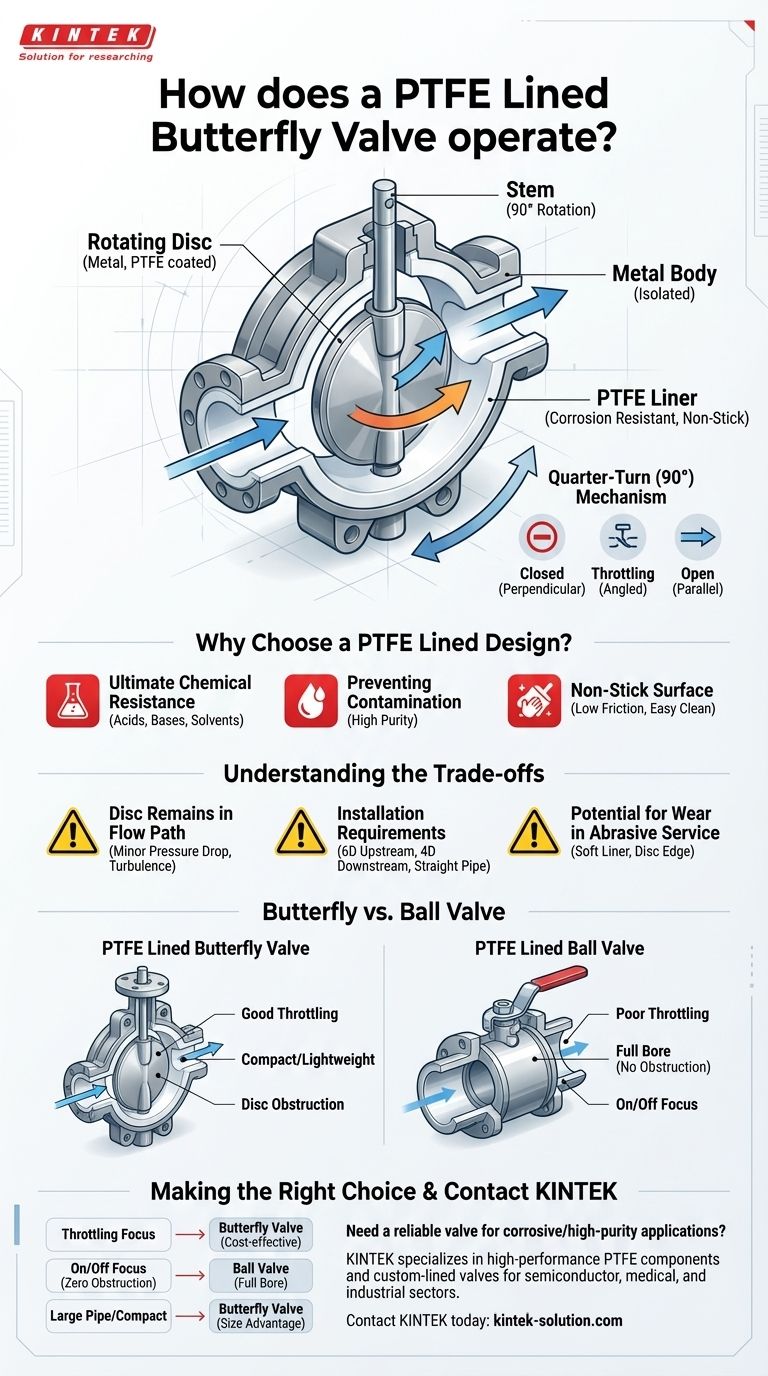

At its core, a PTFE Lined Butterfly Valve operates through a simple and rapid quarter-turn mechanism. A circular disc, mounted on a central stem, rotates 90 degrees within the flow path to start, stop, or regulate the movement of fluid. The critical feature is the polytetrafluoroethylene (PTFE) liner, which completely isolates the valve's metal body from the process media, providing exceptional corrosion resistance.

A PTFE lined butterfly valve is not just a mechanism for controlling flow; it's a specialized solution for corrosive or high-purity applications. Its operation centers on a rotating disc, but its true value comes from the chemically inert PTFE liner that protects both the valve and the process fluid from contamination.

Deconstructing the Operation

A butterfly valve's design is elegant in its simplicity. Understanding its core components clarifies its function in any piping system.

The Quarter-Turn Mechanism

The valve is operated by rotating the stem 90 degrees (a quarter turn). This is often accomplished with a manual gearbox or an actuator for fast and easy operation.

When the disc is rotated to be parallel with the flow, the valve is fully open.

When the disc is rotated to be perpendicular to the flow, it presses against the liner to create a seal, putting the valve in the fully closed position.

The Role of the Disc and Liner

The disc is the gatekeeper of the valve, directly obstructing the flow. However, the fluid never touches the metal disc or the valve body.

Instead, the fluid only makes contact with the PTFE liner. This molded, non-reactive plastic sleeve covers all internal wetted surfaces of the valve. This design ensures that aggressive chemicals or high-purity substances do not corrode the valve or become contaminated by it.

Flow Regulation (Throttling)

Unlike some other quarter-turn valves, a butterfly valve can be used for throttling or regulating flow. By positioning the disc at an angle between fully open and fully closed, you can precisely control the flow rate.

Why Choose a PTFE Lined Design?

The choice of a PTFE lined valve is driven entirely by the need to handle aggressive or sensitive materials safely and effectively.

Ultimate Chemical Resistance

PTFE is one of the most chemically inert materials known. It is resistant to a vast range of acids, bases, and solvents, making it ideal for the chemical processing, pharmaceutical, and food and beverage industries.

Preventing Contamination

Because the liner isolates the process media from the valve's metal components, it prevents leaching and contamination. This is critical for applications demanding high purity.

Non-Stick Surface

PTFE has a very low coefficient of friction, creating a non-stick surface that discourages buildup and makes cleaning processes more effective.

Understanding the Trade-offs

While highly effective, this valve design comes with specific considerations that are critical for successful implementation.

The Disc Remains in the Flow

A key characteristic of all butterfly valves is that the disc remains in the middle of the flow path, even when fully open. This creates a minor pressure drop and can cause some turbulence.

Installation Requirements

For optimal performance and to avoid unpredictable turbulence, these valves should be installed with straight pipe runs. A common guideline is to have at least 6 pipe diameters of straight pipe before the valve and 4 pipe diameters after.

Potential for Wear in Abrasive Service

While excellent for corrosive liquids, the soft PTFE liner can be susceptible to damage from highly abrasive slurries. The sealing edge of the disc can also wear if used for continuous, aggressive throttling.

Butterfly vs. Ball Valve: A Key Distinction

A PTFE lined ball valve is also a quarter-turn valve but uses a rotating ball with a hole through it. When open, it provides a straight, unobstructed flow path (full bore).

However, ball valves are generally poor at throttling. Butterfly valves offer superior flow regulation capabilities, making them a more versatile choice for applications that require more than simple on/off service.

Making the Right Choice for Your Application

Use these guidelines to determine if a PTFE lined butterfly valve fits your objective.

- If your primary focus is flow regulation (throttling) of corrosive media: A PTFE lined butterfly valve is an excellent and cost-effective choice.

- If your primary focus is simple on/off control with zero flow obstruction: A full-bore PTFE lined ball valve is likely the better technical solution.

- If your primary focus is a lightweight, compact, and fast-acting valve for large pipes: The butterfly valve design has a significant advantage in size, weight, and often cost.

By understanding these core operational principles and trade-offs, you can confidently select the right valve for your specific engineering challenge.

Summary Table:

| Aspect | Key Feature | Benefit |

|---|---|---|

| Operation | Quarter-turn (90°) disc rotation | Fast, simple on/off and flow regulation (throttling) |

| Core Component | Molded PTFE liner | Isolates media from metal body, providing ultimate chemical resistance |

| Ideal For | Corrosive, high-purity, or sensitive media | Prevents contamination and protects valve integrity |

| Consideration | Disc remains in flow path | Can cause minor pressure drop and turbulence |

Need a reliable valve for your corrosive or high-purity application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom-lined butterfly valves. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring precision and chemical compatibility.

Whether you need a prototype or a high-volume order, we can fabricate the perfect solution to protect your process and your product.

Contact KINTEK today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE seals chemically inert and suitable for extreme temperatures? The Science of Unmatched Stability

- What are the typical friction coefficient values for PTFE? A Guide to Low-Friction Performance

- What is a Teflon O-ring and what is its primary function? A Guide to Superior Sealing

- What factors should be considered when choosing the thickness of a PTFE gasket? Optimize Your Seal for Flange Condition & Pressure

- What are the benefits of CNC machining for PTFE parts? Achieve Precision and Performance

- What are spring-energized PTFE seals and why are they used? Solve Demanding Sealing Challenges

- Why are PTFE balls suitable for filtering applications? Ensuring Reliable Fluid Control in Demanding Systems

- What are the key properties of PTFE that make it suitable for lined bearings? Discover the Ultimate Low-Friction Solution