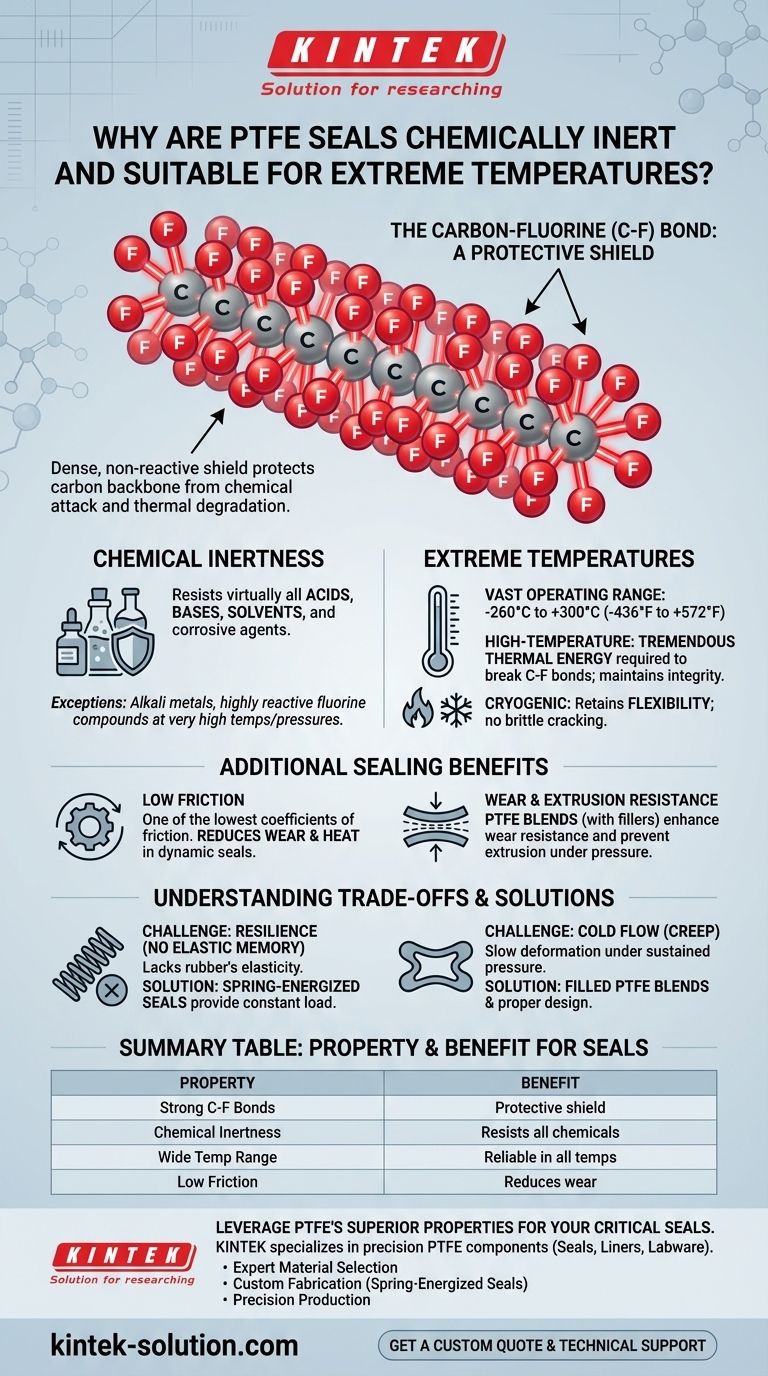

At its core, the remarkable chemical inertness and temperature resistance of Polytetrafluoroethylene (PTFE) stem from its unique molecular structure. The exceptionally strong and stable chemical bonds between carbon and fluorine atoms create a material that is difficult to break down with either chemical or thermal energy.

The source of PTFE's power is the carbon-fluorine bond, one of the strongest single bonds in organic chemistry. This creates a dense, non-reactive "shield" of fluorine atoms that protects the molecule's carbon backbone from both chemical attack and thermal degradation.

The Science Behind PTFE's Stability

To understand why PTFE seals are so robust, we must look at their chemical makeup. The material is a polymer made of a long chain of carbon atoms, where each carbon is bonded to two fluorine atoms.

The Power of the Carbon-Fluorine (C-F) Bond

The bond between carbon and fluorine is incredibly strong and stable. Fluorine is the most electronegative element, meaning it holds onto its electrons very tightly.

This creates a dense and uniform sheath of fluorine atoms around the carbon backbone. This sheath acts as a protective barrier, making it extremely difficult for other chemicals to find a point of attack.

Near-Universal Chemical Inertness

Because of this molecular shield, PTFE is practically inert to all chemicals. It resists acids, bases, solvents, and other corrosive agents that would degrade lesser materials.

The only known exceptions are some alkali metals and highly reactive fluorine compounds at very high temperatures and pressures.

Why PTFE Excels in Extreme Temperatures

The same molecular stability that provides chemical resistance also gives PTFE its vast operating temperature range, typically cited from -260°C to +300°C (-436°F to +572°F).

High-Temperature Performance

A tremendous amount of thermal energy is required to break the strong C-F bonds and cause the material to degrade. This allows PTFE seals to maintain their structural integrity and sealing ability in environments like automotive engines and high-temperature sterile processes.

Cryogenic and Low-Temperature Resilience

Unlike many polymers that become brittle and crack at low temperatures, PTFE retains its flexibility and sealing properties even in cryogenic applications. Its stable structure does not undergo the phase changes that lead to failure in other materials.

From Material Property to Sealing Performance

While inertness and temperature resistance are key, other properties make PTFE an exceptional choice for sealing applications.

Incredibly Low Friction

PTFE has one of the lowest coefficients of friction of any known solid. This is critical in dynamic seals, as it reduces wear and heat generation, extending the life of both the seal and the mating components.

High Wear and Extrusion Resistance

While pure PTFE can be soft, it is often combined with fillers to create PTFE blends. These blends enhance properties like wear resistance and prevent the seal from being pushed out of its groove under high pressure (extrusion).

Understanding the Trade-offs

No material is perfect. Acknowledging the limitations of PTFE is crucial for proper seal design and application.

The Challenge of Resilience

PTFE is a relatively rigid plastic and lacks the "memory" or elasticity of rubber. It will not spring back to its original shape after being compressed.

This is why many high-performance PTFE seals are spring-energized. A metal spring provides a constant load, compensating for the polymer's lack of resilience and ensuring a tight seal even with wear or thermal cycling.

Tendency for Cold Flow

Under sustained pressure, especially at elevated temperatures, PTFE can slowly deform over time in a process called "creep" or "cold flow."

Using filled PTFE blends and proper hardware design are essential strategies to mitigate this effect in high-pressure applications.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the material's properties to the demands of the environment.

- If your primary focus is aggressive chemicals: Pure PTFE is often the default choice due to its near-universal inertness.

- If your primary focus is high temperature and pressure: A spring-energized seal made from a filled PTFE blend will provide thermal stability and resistance to extrusion.

- If your primary focus is dynamic or rotary sealing: PTFE's low-friction properties will minimize heat buildup and wear, making it a superior choice to many elastomers.

- If your primary focus is cryogenic sealing: PTFE is one of the few materials that retains the necessary properties to create a reliable seal at extremely low temperatures.

Ultimately, understanding the fundamental molecular strengths of PTFE empowers you to deploy it with confidence in your most demanding applications.

Summary Table:

| Property | Benefit for Seals |

|---|---|

| Strong C-F Bonds | Creates a protective shield against chemical attack and thermal degradation. |

| Chemical Inertness | Resists virtually all acids, bases, and solvents. |

| Wide Temp Range (-260°C to +300°C) | Performs reliably in both high-heat and cryogenic environments. |

| Low Friction | Reduces wear and heat in dynamic applications. |

Leverage PTFE's Superior Properties for Your Critical Seals

Do you need reliable sealing solutions for aggressive chemicals, extreme temperatures, or high-pressure environments? The science is clear: PTFE offers unmatched performance.

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors by providing:

- Expert Material Selection: Guidance on pure PTFE for maximum chemical resistance or filled blends for enhanced wear and pressure resistance.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions like spring-energized seals to meet your exact application demands.

- Precision Production: Ensuring every component delivers the reliability your operations depend on.

Contact us today to discuss how our PTFE expertise can solve your most challenging sealing problems.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance