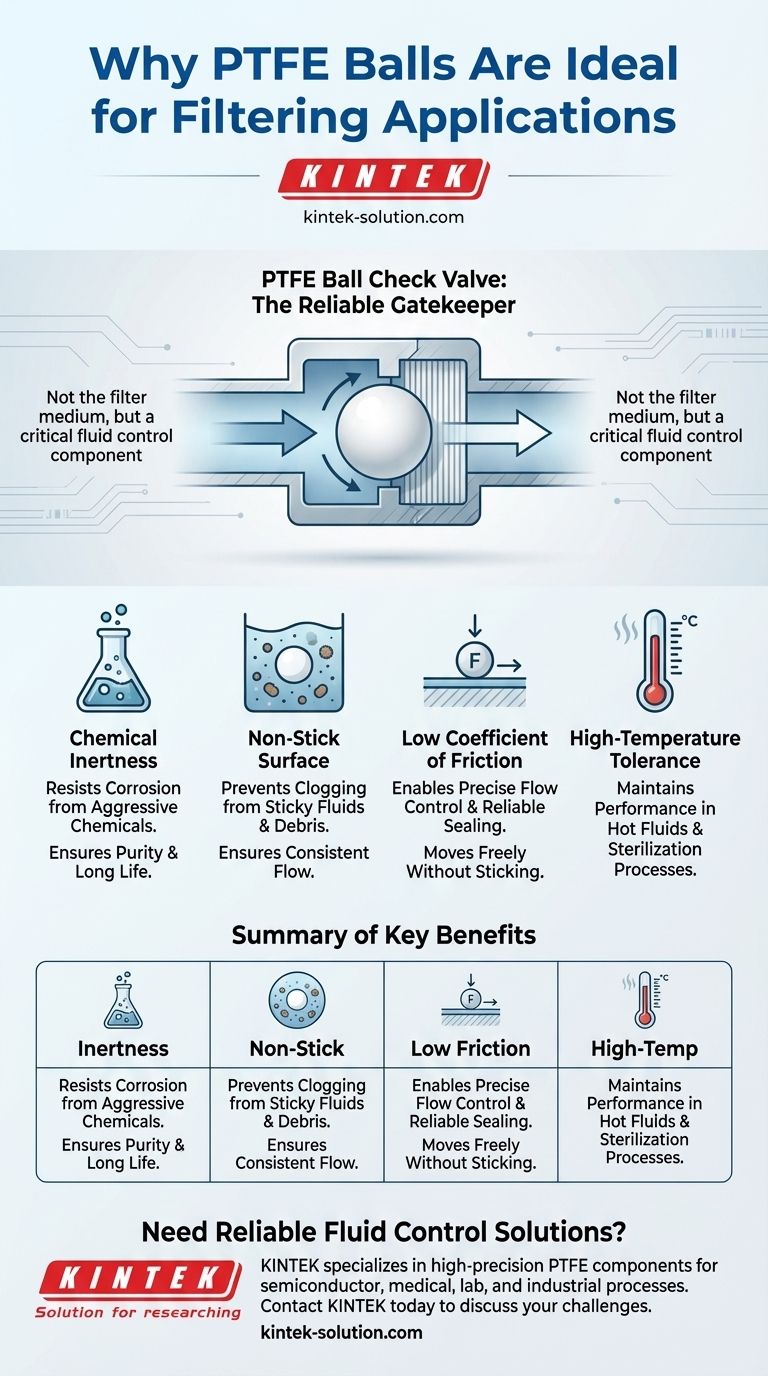

At its core, PTFE balls are ideal for filtering applications not as the filter medium itself, but as a critical component—typically a check valve—for controlling fluid flow. Their suitability comes from a unique combination of chemical inertness, a non-stick surface, and an extremely low coefficient of friction, which together ensure reliable, long-term operation without clogging or degradation.

The crucial insight is that PTFE balls solve the most common failure points within a filtering system: sticking, clogging, and chemical corrosion. They aren't the filter; they are the reliable gatekeeper that ensures the system functions as intended, especially when handling difficult or aggressive fluids.

The Role of PTFE Balls in Fluid Control Systems

When discussing filtering applications, it's essential to understand that PTFE balls are almost always used to manage the movement of the fluid, not to perform the separation of particles. Their primary role is as the sealing element in a check valve.

How a Check Valve Works

A check valve is a simple device that allows fluid to flow in only one direction. It consists of a seat and a moving component, often a ball.

When fluid flows in the correct direction, it pushes the ball off the seat, opening the valve. If the flow tries to reverse, it pushes the ball back into the seat, creating a seal and stopping the backflow.

Why the Ball's Material is Critical

The ball is the only moving part and is in constant contact with the fluid. Its material properties directly determine the valve's reliability and lifespan. If the ball sticks, corrodes, or gets clogged with debris, the entire valve—and thus the filtering system—fails.

Key Properties and Their Practical Impact

PTFE (Polytetrafluoroethylene) offers a set of properties that make it uniquely suited for this demanding role, outperforming materials like rubber or stainless steel in specific contexts.

Exceptional Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This means it will not corrode, degrade, or leach contaminants into the fluid being filtered, which is critical for maintaining purity and ensuring the longevity of the valve, especially when handling corrosive substances.

Non-Stick (Anti-Adhesive) Surface

This is perhaps its most significant advantage in filtering contexts. The non-stick surface prevents viscous liquids, sticky materials, or particulates from adhering to the ball. This directly prevents the valve from clogging or fouling, ensuring fluid can flow smoothly and consistently over long periods.

Low Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid material. This property ensures the ball can move freely off its seat with minimal pressure and return to create a perfect seal without sticking. This responsiveness is key to the valve's efficient and reliable operation.

High-Temperature Tolerance

PTFE maintains its properties across a wide range of temperatures. This allows PTFE balls to be used in systems that handle hot fluids or require high-temperature sterilization processes without the material deforming or degrading.

Common Pitfalls and Clarifications

While highly effective, it's important to understand the precise role and limitations of PTFE balls to avoid misapplication.

They Are Not a Filter Medium

The most common point of confusion is thinking the balls themselves perform the filtration. They do not. They are a component within a larger system that enables the control of fluid flow to or from the actual filter element.

Mechanical Strength Limitations

PTFE is a relatively soft thermoplastic. While durable in its intended application, it is not suitable for high-pressure or high-load mechanical situations where a harder material like stainless steel or ceramic would be required. The references note their use in ball bearings is typically for "light loads."

Making the Right Choice for Your Application

Selecting the right material for your fluid control components is a decision based on the specific challenges of your process.

- If your primary focus is handling aggressive or corrosive chemicals: PTFE's chemical inertness is its greatest strength, preventing component failure and fluid contamination.

- If your primary focus is filtering sticky or particulate-laden fluids: PTFE's non-stick surface is the key property that prevents valve clogging and ensures reliable flow.

- If your primary focus is long-term reliability with minimal maintenance: The combined properties of PTFE reduce wear, fouling, and sticking, making it a superior choice over materials that degrade or require frequent cleaning.

Ultimately, choosing PTFE balls is a decision for operational resilience, ensuring the fluid control components in your system perform reliably under demanding conditions.

Summary Table:

| Key Property | Benefit in Filtering Applications |

|---|---|

| Chemical Inertness | Resists corrosion from aggressive chemicals, ensuring purity and long component life. |

| Non-Stick Surface | Prevents clogging from sticky or particulate-laden fluids, ensuring consistent flow. |

| Low Friction | Allows the ball to move and seal reliably without sticking, enabling precise flow control. |

| High-Temperature Tolerance | Maintains performance in systems with hot fluids or sterilization processes. |

Need a reliable, long-lasting fluid control solution for your demanding processes?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Our expertise ensures that your fluid control systems—whether for semiconductor manufacturing, medical devices, laboratory analysis, or industrial processing—benefit from the superior chemical resistance and non-stick properties of PTFE.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE components can solve your specific fluid control challenges and enhance the reliability of your filtering systems.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments