In essence, a spring-energized PTFE seal is a high-performance sealing device that combines a durable polymer jacket, typically made of Polytetrafluoroethylene (PTFE), with a corrosion-resistant metal spring. The spring provides a constant, live force that pushes the seal lips against the mating surfaces. This design creates a highly reliable seal that adapts to changing conditions where traditional elastomeric seals would fail.

The central challenge with PTFE is that it's an exceptional sealing material that lacks elasticity—it doesn't "bounce back" on its own. The internal spring solves this fundamental weakness, providing the constant outward force needed to maintain a tight seal despite wear, pressure changes, or temperature fluctuations.

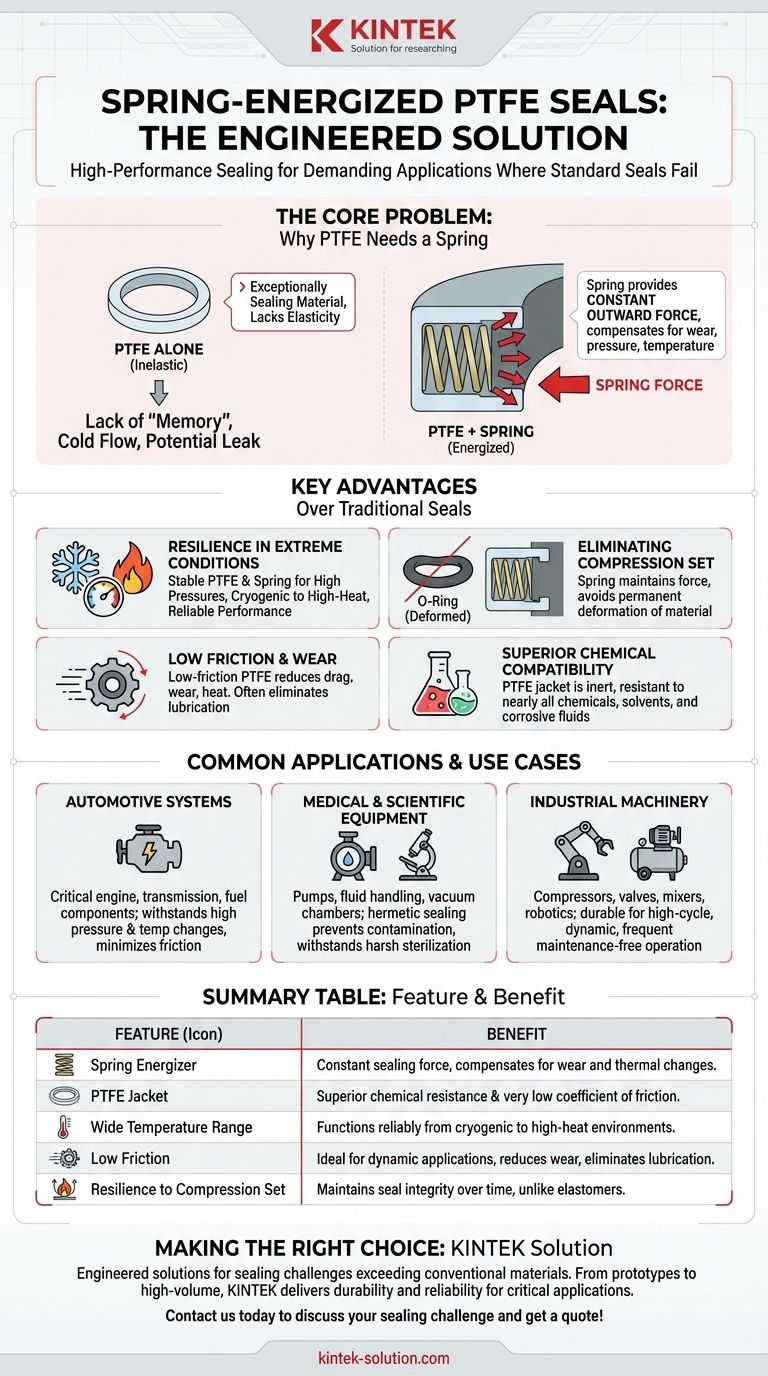

The Core Problem: Why PTFE Needs a Spring

To understand the value of this design, you must first understand the unique properties of its primary material, PTFE.

The Strengths of PTFE

PTFE is renowned for its exceptional characteristics. It offers a very low coefficient of friction, making it ideal for dynamic applications where minimizing drag and heat is critical.

It also has an extremely wide operating temperature range and is almost completely chemically inert, allowing it to function in cryogenic fluids or aggressive chemical environments.

The Weakness of PTFE: Inelasticity

The major limitation of PTFE is its lack of "memory" or elasticity. Unlike a rubber O-ring, it doesn't naturally return to its original shape after being compressed.

This can lead to a phenomenon known as "cold flow" or creep, where the material slowly deforms under load, potentially causing a leak over time.

The Spring's Role: Providing Constant Force

The internal metal spring is the solution to PTFE's inelasticity. It acts as an energizer, applying a continuous radial force to the PTFE jacket.

This constant outward pressure ensures the seal lips remain in firm contact with the sealing surfaces. It automatically compensates for seal wear, thermal expansion or contraction, and minor gland misalignment, ensuring a reliable seal throughout its service life.

Key Advantages Over Traditional Seals

The spring-energized design gives these seals a distinct performance edge over simpler solutions like standard PTFE or elastomeric O-rings in demanding situations.

Resilience in Extreme Conditions

The combination of a stable PTFE jacket and a metal spring allows these seals to perform reliably under high pressures and across a vast temperature spectrum, from cryogenic liquids to high-heat applications.

Eliminating Compression Set

Elastomeric (rubber) seals can permanently deform when held under compression for long periods, a failure known as compression set. Spring-energized seals avoid this issue entirely because the spring, not the material's elasticity, maintains the sealing force.

Low Friction and Wear

The inherently low friction of the PTFE jacket reduces wear and heat generation in dynamic applications like motors, pumps, and robotics. This often eliminates the need for lubrication and improves overall system efficiency.

Superior Chemical Compatibility

The PTFE jacket is resistant to nearly all chemicals, solvents, and corrosive fluids. This makes it a critical component in medical equipment that undergoes harsh sterilization processes or in fuel systems exposed to aggressive additives.

Common Applications and Use Cases

You will find spring-energized seals in environments where failure is not an option and performance is paramount.

Automotive Systems

They are used in critical engine components, transmissions, and fuel systems where they must withstand high pressures and rapid temperature changes while minimizing frictional losses.

Medical and Scientific Equipment

In pumps, fluid handling systems, and vacuum chambers, these seals provide hermetic sealing to prevent contamination. Their chemical resistance is essential for withstanding aggressive disinfectants and sterilization cycles.

Industrial Machinery

They are a mainstay in demanding industrial equipment such as compressors, valves, mixers, and robotics. Their durability and reliability are ideal for high-cycle, dynamic applications where frequent maintenance is impractical.

Making the Right Choice for Your Application

Choosing a spring-energized seal is about matching its specific capabilities to the demands of your environment.

- If your primary focus is extreme temperature or pressure: These seals provide reliable performance where elastomers would degrade or fail.

- If your primary focus is chemical compatibility: The inert PTFE jacket makes this seal the default choice for aggressive chemical or sterile environments.

- If your primary focus is low-friction dynamic sealing: This design offers superior efficiency and wear resistance in high-speed or unlubricated machinery.

- If your primary focus is a standard, static application: A simpler, less expensive elastomeric O-ring is likely sufficient for less demanding conditions.

Ultimately, a spring-energized PTFE seal is an engineered solution for sealing challenges that exceed the limits of conventional materials.

Summary Table:

| Feature | Benefit |

|---|---|

| Spring Energizer | Provides constant sealing force, compensates for wear and thermal changes. |

| PTFE Jacket | Offers superior chemical resistance and a very low coefficient of friction. |

| Wide Temperature Range | Functions reliably from cryogenic to high-heat environments. |

| Low Friction | Ideal for dynamic applications, reduces wear, and can eliminate lubrication. |

| Resilience to Compression Set | Maintains seal integrity over time, unlike elastomers that can permanently deform. |

Need a reliable seal for a demanding application?

Spring-energized PTFE seals from KINTEK are engineered for performance where standard seals fail. Whether you're designing for the semiconductor, medical, laboratory, or industrial sector, our expertise in precision PTFE component manufacturing ensures a perfect fit for your unique requirements.

We specialize in custom fabrication, from prototypes to high-volume orders, delivering the durability and reliability your critical applications demand.

Contact us today to discuss your specific sealing challenge and get a quote! #ContactForm

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs