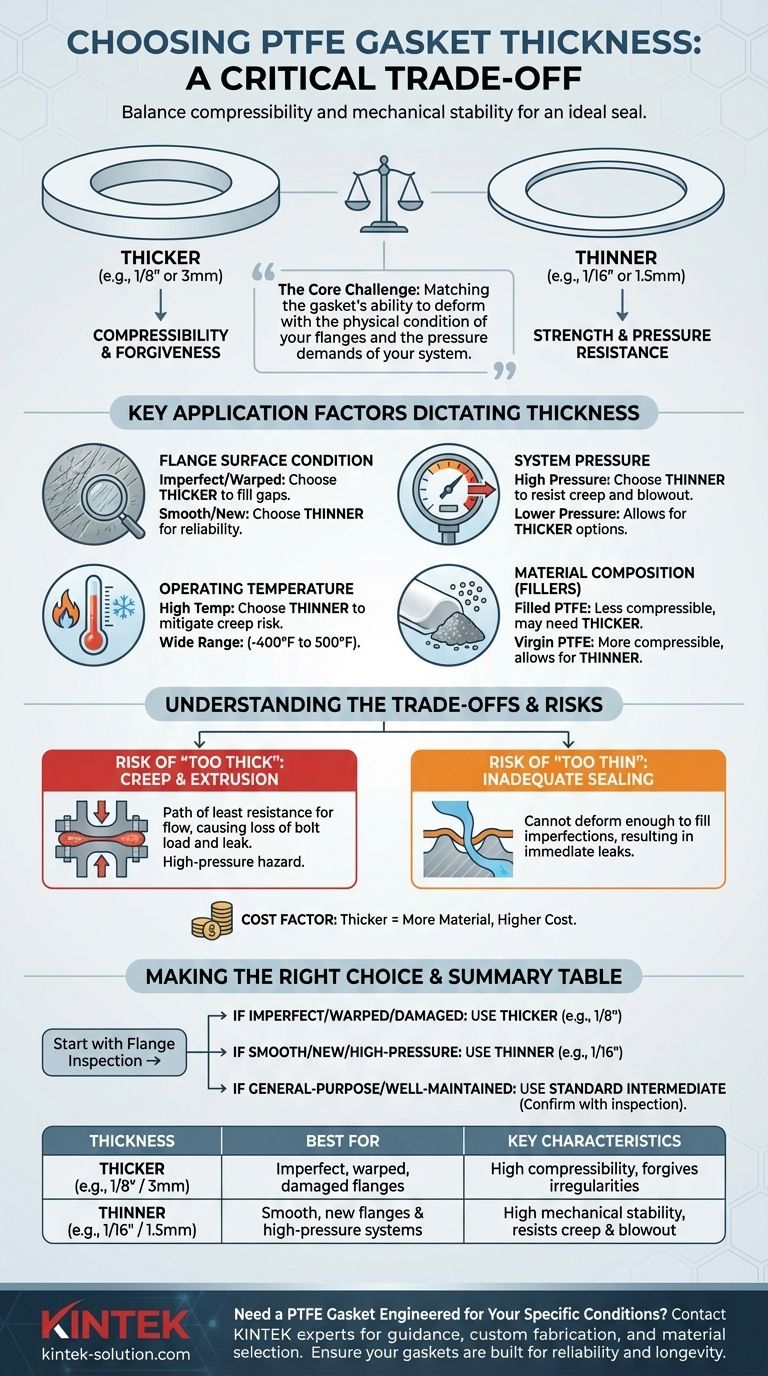

When choosing a PTFE gasket thickness, you are making a critical trade-off between compressibility and mechanical stability. A thicker gasket offers more forgiveness for imperfect surfaces, allowing it to compress and fill gaps effectively. Conversely, a thinner gasket provides greater strength and resistance to being pushed out under high pressure, making it ideal for smooth, well-aligned flanges.

The core challenge is not simply picking a thickness, but matching the gasket's ability to deform with the physical condition of your flanges and the pressure demands of your system. An ideal seal is achieved when the gasket is just thick enough to fill surface imperfections but thin enough to resist creep and blowout.

The Core Principle: Sealing vs. Stability

The choice between a thick and a thin gasket comes down to a fundamental mechanical conflict. You must balance the need for the material to flow and seal against its need to remain in place under load.

Thicker Gaskets for Compressibility and Forgiveness

Thicker gaskets (e.g., 1/8" or 3mm) are more forgiving. Their extra material allows them to compress and conform to surface irregularities.

This makes them the superior choice for flanges that are warped, pitted, scratched, or slightly misaligned. The gasket essentially fills in the gaps to create a continuous seal.

Thinner Gaskets for Strength and Pressure Resistance

Thinner gaskets (e.g., 1/16" or 1.5mm) are stronger and more stable. Because there is less material, they have a much lower tendency to creep or extrude under high pressure.

When you have smooth, clean, and perfectly aligned flange surfaces, a thinner gasket provides a more robust and reliable seal, especially in high-pressure applications.

Key Application Factors That Dictate Thickness

While the principle of sealing versus stability is universal, your specific operating environment determines where you should land on that spectrum.

Flange Surface Condition

This is the most important factor. Carefully inspect your flanges. Old, damaged, or heavily used flanges with visible scratches or warping require a thicker gasket to ensure a proper seal.

For new or recently machined flanges that are perfectly flat and smooth, a thinner gasket is the more reliable and cost-effective choice.

System Pressure

High internal pressure exerts a significant outward force on the gasket. A thick gasket is more susceptible to creep, where the material slowly flows out from between the flanges, leading to a loss of bolt torque and an eventual leak.

For this reason, high-pressure systems demand thinner gaskets that offer greater mechanical stability.

Operating Temperature

PTFE has an exceptionally wide operating temperature range (typically -400°F to 500°F / -240°C to 260°C). However, at the higher end of this range, the material becomes softer and more prone to creep.

In high-temperature applications, using a thinner gasket can help mitigate this risk by providing less material to deform under load.

Material Composition (Fillers)

Not all PTFE is the same. Some PTFE gaskets include fillers like glass or carbon to increase hardness, stiffness, and durability.

A filled, harder PTFE gasket will be less compressible than a pure, virgin PTFE gasket. You may need to select a slightly thicker filled gasket to achieve the same level of sealing on an imperfect surface that a thinner, virgin PTFE gasket could handle.

Understanding the Trade-offs

Choosing incorrectly has direct consequences for safety, performance, and cost. Understanding the risks of going too far in either direction is critical.

The Risk of "Too Thick": Creep and Extrusion

Using a gasket that is too thick for a high-pressure application is a primary cause of seal failure. The excessive material provides a path of least resistance for flow.

The gasket will be squeezed out from between the flanges, causing a loss of bolt load and creating a leak path. This is a significant safety hazard in chemical or high-pressure service.

The Risk of "Too Thin": Inadequate Sealing

Using a gasket that is too thin for the flange surface condition will result in an immediate or short-term leak.

The gasket material simply cannot deform enough to fill the microscopic valleys, scratches, or warped areas, leaving a direct path for fluid or gas to escape.

The Cost Factor

Thicker gaskets require more raw material and are therefore more expensive. While the price difference for a single gasket may seem small, it becomes significant across an entire facility.

Over-specifying gasket thickness for well-maintained flanges is an unnecessary expense. Raw PTFE material costs can fluctuate, making right-sizing a financially sound practice.

Making the Right Choice for Your Application

Analyze your specific system to make an informed decision. There is no single universal solution, only the right choice for a given application.

- If your primary focus is sealing old, warped, or damaged flanges: Start with a thicker gasket (e.g., 1/8" or 3mm) to ensure it can effectively fill all surface imperfections.

- If your primary focus is handling high pressure with smooth, new flanges: Use a thinner gasket (e.g., 1/16" or 1.5mm) to maximize stability and resistance to creep and blowout.

- If you are balancing cost and general-purpose use on well-maintained equipment: A standard intermediate thickness is often a safe default, but this should always be confirmed by a visual inspection of the flange surfaces.

Ultimately, a careful inspection of your flange surfaces is the most critical step in determining the correct gasket thickness for a reliable seal.

Summary Table:

| Thickness | Best For | Key Characteristics |

|---|---|---|

| Thicker (e.g., 1/8" / 3mm) | Imperfect, warped, or damaged flanges | High compressibility, forgives surface irregularities |

| Thinner (e.g., 1/16" / 1.5mm) | Smooth, new flanges & high-pressure systems | High mechanical stability, resists creep and blowout |

Need a PTFE Gasket Engineered for Your Specific Conditions?

Choosing the right thickness is critical for a safe, reliable, and cost-effective seal. KINTEK specializes in manufacturing precision PTFE components, including custom gaskets, for the semiconductor, medical, laboratory, and industrial sectors.

We can help you optimize your seal by:

- Providing expert guidance on material selection and thickness for your flange condition and operating parameters.

- Delivering high-quality, custom-fabricated PTFE gaskets from prototypes to high-volume orders, ensuring perfect performance.

- Utilizing filled or virgin PTFE compounds to meet your exact requirements for hardness, chemical resistance, and temperature stability.

Don't leave your seal performance to chance. Contact our experts today for a consultation and ensure your gaskets are built for reliability and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F