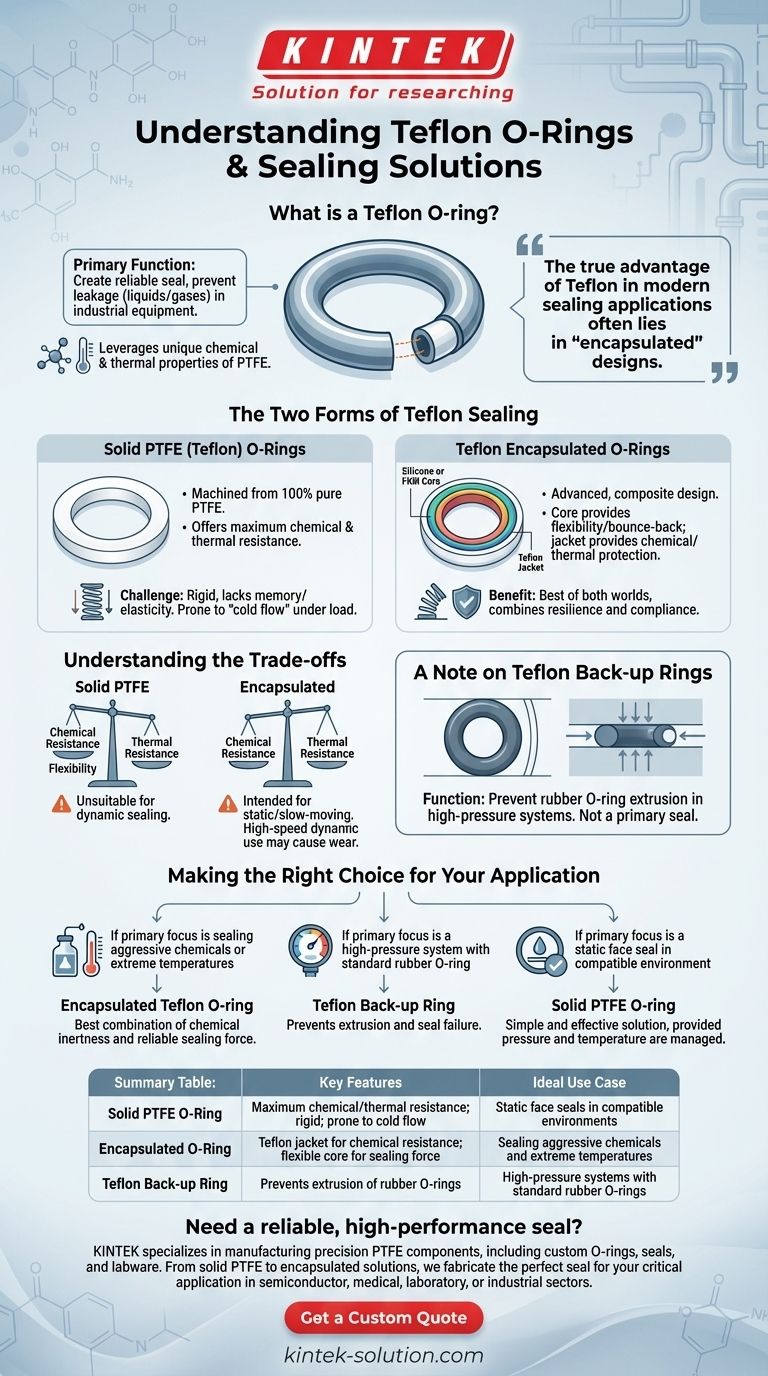

At its core, a Teflon O-ring is a sealing component made from Polytetrafluoroethylene (PTFE). Its primary function is to create a reliable seal in industrial equipment, preventing the leakage of liquids or gases. This is achieved by leveraging the unique chemical and thermal properties of the PTFE material in a classic O-ring design.

The true advantage of Teflon in modern sealing applications often lies in "encapsulated" designs. These combine the extreme chemical resistance of a Teflon outer jacket with the flexibility of a traditional rubber core, offering a solution that is both resilient and compliant.

The Two Forms of Teflon Sealing

When discussing Teflon O-rings, it's critical to distinguish between two different constructions: solid PTFE rings and Teflon encapsulated rings. They serve similar purposes but have very different mechanical properties.

Solid PTFE (Teflon) O-Rings

A solid O-ring is machined from 100% pure PTFE material. It offers the maximum chemical and thermal resistance that Teflon is known for.

However, solid PTFE is a rigid material. It lacks the memory and elasticity of rubber, meaning it does not spring back into shape effectively after being compressed.

Teflon Encapsulated O-Rings

This is a more advanced, composite design. It consists of a flexible elastomeric core, typically made of Silicone or FKM (Viton®), which is completely enclosed in a seamless Teflon jacket.

This construction provides the best of both worlds. The inner core provides the flexibility and "bounce-back" needed for a consistent, long-term seal, while the outer jacket provides protection from harsh chemicals and extreme temperatures.

Understanding the Trade-offs

Choosing the right seal requires understanding the limitations and specific use cases for each type. Misapplication can lead to seal failure.

The Challenge of Inflexibility

Solid PTFE O-rings are best suited for static applications, where there is no movement between the sealing faces. Their rigidity makes them unsuitable for dynamic sealing, and their tendency to deform permanently under load (a trait known as "cold flow") can compromise the seal over time.

The Limits of Encapsulation

While highly versatile, encapsulated O-rings are more expensive than standard rubber O-rings. They are also primarily intended for static or very slow-moving applications, as high-speed dynamic use could cause premature wear on the Teflon jacket.

A Note on Teflon Back-up Rings

It is important not to confuse Teflon O-rings with Teflon back-up rings. A back-up ring is a thin, hard ring that sits alongside a traditional rubber O-ring. Its sole function is to prevent the softer rubber O-ring from being physically squeezed, or "extruded," into the clearance gap under high pressure.

Making the Right Choice for Your Application

Selecting the correct component is essential for equipment reliability and safety. Your decision should be guided by the specific demands of the operating environment.

- If your primary focus is sealing aggressive chemicals or extreme temperatures: An encapsulated Teflon O-ring offers the best combination of chemical inertness and reliable sealing force.

- If your primary focus is a high-pressure system with a standard rubber O-ring: A Teflon back-up ring is the correct component to prevent extrusion and seal failure.

- If your primary focus is a static face seal in a compatible chemical environment: A solid PTFE O-ring can be a simple and effective solution, provided the pressure and temperature are managed.

Ultimately, understanding these material properties empowers you to select a seal that ensures the long-term integrity of your system.

Summary Table:

| Type | Key Features | Ideal Use Case |

|---|---|---|

| Solid PTFE O-Ring | Maximum chemical/thermal resistance; rigid; prone to cold flow | Static face seals in compatible environments |

| Encapsulated O-Ring | Teflon jacket for chemical resistance; flexible core for sealing force | Sealing aggressive chemicals and extreme temperatures |

| Teflon Back-up Ring | Prevents extrusion of rubber O-rings | High-pressure systems with standard rubber O-rings |

Need a reliable, high-performance seal for your critical application?

KINTEK specializes in manufacturing precision PTFE components, including custom O-rings, seals, and labware. Whether you require the ultimate chemical resistance of a solid PTFE design or the resilient flexibility of an encapsulated solution, our team can fabricate the perfect seal—from prototypes to high-volume orders.

Contact us today to discuss how our sealing solutions can enhance the integrity and longevity of your equipment in the semiconductor, medical, laboratory, or industrial sectors.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key properties of PTFE Teflon O-rings? Unmatched Chemical & Thermal Resistance

- What types of media can PTFE lined butterfly valves handle in industrial applications? Ensure Chemical Resistance and Purity

- What are the sealing capabilities of PTFE lined check valves? Achieve Superior Corrosion Resistance

- How do PTFE seals compare to traditional sealing materials in terms of service life? Extend Equipment Lifespan Dramatically

- What are the advantages of PTFE envelope gaskets in flange connections? Seal Sensitive Flanges with Low Bolt Load

- What temperature range can standard PTFE lip seals typically withstand? A Guide to Extreme-Temp Performance

- What are the advantages of using PTFE rotary seals over rubber elastomer seals? Superior Performance in Extreme Conditions

- What are common applications of machined Teflon/PTFE parts? Solve Extreme Engineering Challenges