In short, PTFE lined butterfly valves are designed to handle a vast range of highly corrosive and high-purity media. They are workhorses in industries where chemical resistance is paramount, safely transporting everything from aggressive acids and petrochemicals to ultrapure water and pharmaceutical ingredients. Their versatility extends to both liquids and gases.

The core principle to understand is that PTFE lined butterfly valves are chosen for their exceptional chemical inertness, not their resistance to abrasion. While they excel with corrosive and pure substances, their performance is compromised by media containing hard, abrasive particles.

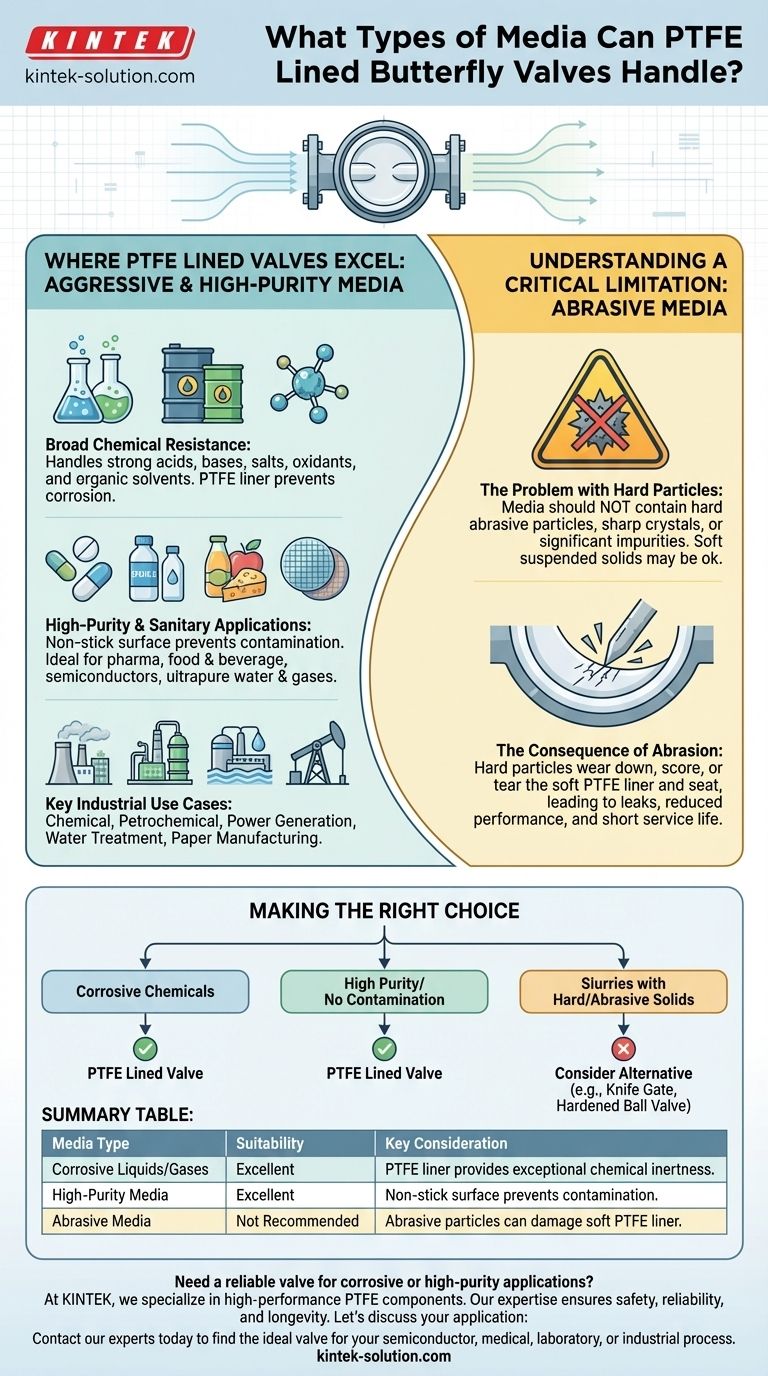

Where PTFE Lined Valves Excel: Handling Aggressive and High-Purity Media

The effectiveness of these valves comes from the unique properties of Polytetrafluoroethylene (PTFE), the lining material. This liner isolates the valve's structural components from the process media.

Broad Chemical Resistance

PTFE is one of the most chemically inert polymers available. This makes the valves suitable for an extensive list of aggressive media.

This includes strong acids, bases, salts, oxidants, and a wide variety of organic solvents. The liner ensures the valve body is not corroded by the fluid it controls.

High-Purity and Sanitary Applications

The non-stick nature of PTFE is a critical advantage in sensitive industries.

This property prevents media from accumulating on the valve's surfaces, which is crucial for preventing contamination in pharmaceutical, food and beverage, and semiconductor applications. They are frequently used for transporting ultrapure water and gases.

Key Industrial Use Cases

Their unique combination of corrosion resistance and cleanliness makes them indispensable across several demanding sectors.

Common industries include chemical processing, petrochemicals, power generation, water treatment, and paper manufacturing. The ability to handle hazardous materials safely makes them vital for environmental protection and safety systems.

Understanding a Critical Limitation: Abrasive Media

While versatile, these valves have a distinct operational boundary that must be respected to ensure reliability and longevity. The very softness that helps PTFE create a tight seal also makes it vulnerable.

The Problem with Hard Particles

The process medium should not contain hard, abrasive particles, sharp crystals, or significant impurities.

Some applications may involve slurries with soft suspended solids, but this is a critical distinction. Abrasive materials will physically damage the liner.

The Consequence of Abrasion

Hard particles moving through the valve can wear down, score, or tear the soft PTFE liner and seat during operation.

This damage directly compromises the valve's sealing capability, leading to leaks, reduced performance, and a significantly shorter service life. Ultimately, it negates the valve's core benefit of providing a secure seal.

Making the Right Choice for Your Application

Selecting the correct valve requires a clear understanding of your process media's characteristics.

- If your primary focus is handling corrosive chemicals: A PTFE lined butterfly valve is an excellent choice due to its superior chemical inertness.

- If your primary focus is ensuring high purity or preventing contamination: The non-stick surface of the PTFE liner makes it an ideal solution for your application.

- If your primary focus is transporting slurries with hard or abrasive solids: You should strongly consider alternative valve types, such as a knife gate or a specifically hardened ball valve, to avoid rapid liner failure.

Ultimately, matching the valve's capabilities to the nature of your media is the key to ensuring a safe, reliable, and long-lasting installation.

Summary Table:

| Media Type | Suitability | Key Consideration |

|---|---|---|

| Corrosive Liquids/Gases (Acids, Bases, Solvents) | Excellent | PTFE liner provides exceptional chemical inertness. |

| High-Purity Media (Ultrapure Water, Pharma Ingredients) | Excellent | Non-stick surface prevents contamination. |

| Abrasive Media (Slurries with Hard Particles) | Not Recommended | Abrasive particles can damage the soft PTFE liner. |

Need a reliable valve for corrosive or high-purity applications?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom solutions for critical flow control. Our expertise ensures you get a valve perfectly matched to your media's specific chemical and purity requirements, guaranteeing safety, reliability, and longevity.

Let's discuss your application: Contact our experts today to find the ideal PTFE lined valve for your semiconductor, medical, laboratory, or industrial process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability