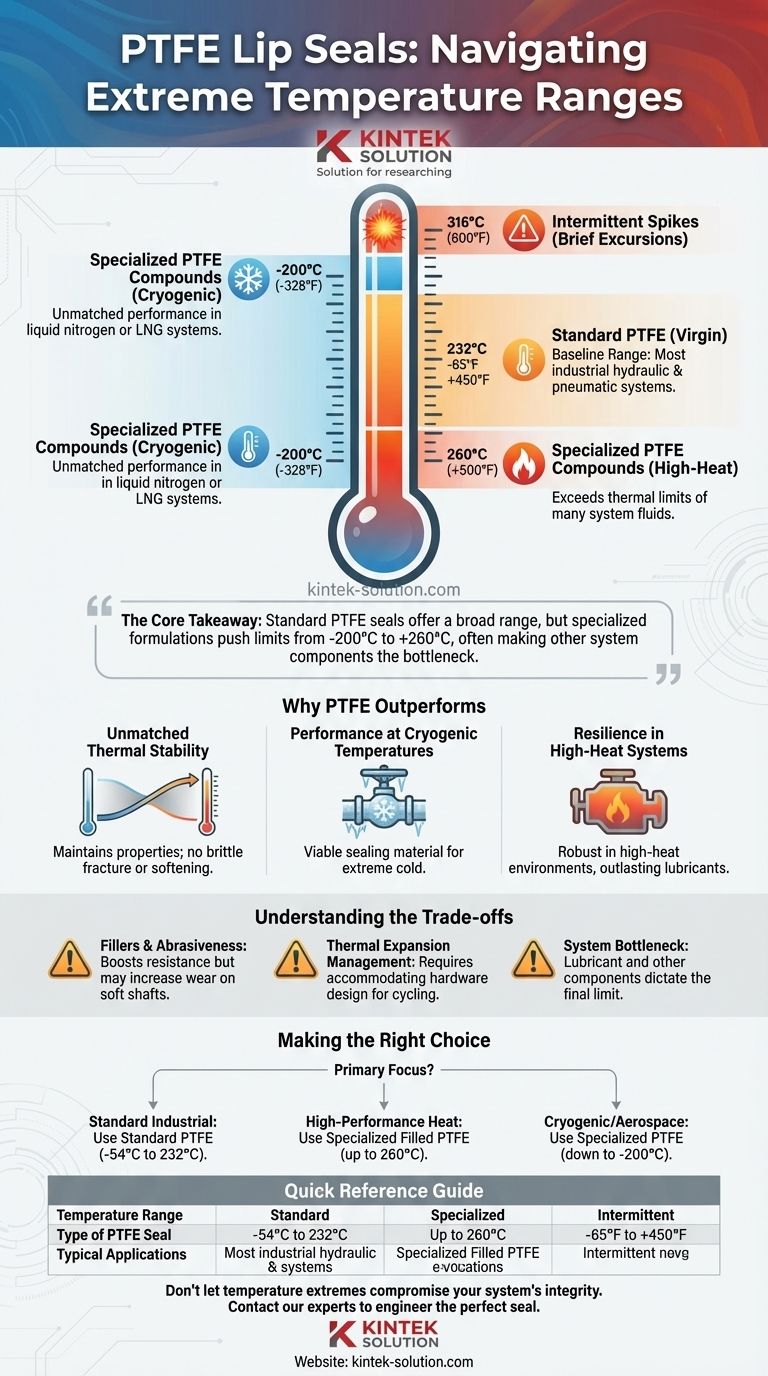

To be precise, a standard PTFE lip seal typically operates within a temperature range of -54°C to 232°C (-65°F to +450°F). However, this is only the baseline, as specialized PTFE compounds can dramatically extend this operational window to handle far more extreme conditions, from cryogenic lows to high-heat environments.

The core takeaway is that while standard PTFE seals offer a broad temperature range, their true value lies in specialized formulations. These advanced compounds can push operational limits from -200°C to +260°C (-328°F to +500°F), often making other system components—like lubricants—the actual limiting factor.

Deconstructing the Temperature Ratings

Understanding the numbers requires looking beyond a single specification. The effective temperature range of a PTFE seal depends on its specific composition and the nature of the thermal exposure it will face.

The Baseline for Standard PTFE

A "standard" seal generally refers to one made from virgin or unfilled PTFE. This material provides an excellent balance of properties and is highly effective within its -54°C to 232°C (-65°F to +450°F) range, which covers the vast majority of industrial hydraulic and pneumatic applications.

Pushing the Limits with Specialized Compounds

Engineers can enhance the properties of PTFE by adding fillers. Materials like glass fiber, carbon, or graphite can significantly improve thermal stability and wear resistance. These specialized compounds are responsible for the much wider -200°C to 260°C (-328°F to +500°F) range often cited for high-performance seals.

The Critical Role of Intermittent Spikes

It is crucial to distinguish between continuous and intermittent temperatures. Some specialized PTFE seals are engineered to withstand temporary temperature spikes up to 316°C (600°F) without catastrophic failure, even if their continuous rating is lower. This provides a critical safety margin in systems prone to brief thermal excursions.

Why PTFE Outperforms in Extreme Temperatures

PTFE's molecular structure gives it an inherent advantage over traditional elastomeric (rubber) seals when temperatures fluctuate. It maintains its integrity where others fail.

Unmatched Thermal Stability

Unlike elastomers that can become brittle at low temperatures or soften and degrade at high temperatures, PTFE maintains its key mechanical properties across its entire range. This stability ensures a reliable seal in applications with wide and unpredictable temperature swings.

Performance at Cryogenic Temperatures

The ability to function down to -200°C (-328°F) makes specialized PTFE one of the few viable sealing materials for cryogenic applications, such as in liquid nitrogen or LNG systems. Most other materials lose their flexibility and sealing capability long before reaching these temperatures.

Resilience in High-Heat Systems

At the upper end, PTFE's ability to withstand 260°C (500°F) often exceeds the thermal limits of the system's fluids. For example, most hydraulic fluids begin to oxidize and break down well below this temperature, making the PTFE seal one of the most robust components in the thermal chain.

Understanding the Trade-offs and Considerations

While PTFE offers exceptional thermal performance, it is not a universal solution. Effective implementation requires acknowledging its unique properties and potential limitations.

Fillers Alter More Than Just Temperature

Adding fillers like glass to boost temperature resistance can also increase the abrasiveness of the seal. This can lead to increased wear on softer shaft materials, a critical trade-off that must be considered during the design phase.

Thermal Expansion Must Be Managed

PTFE has a higher coefficient of thermal expansion compared to metals. In applications with significant temperature cycles, the hardware and gland design must accommodate this expansion and contraction to maintain the proper sealing force and prevent extrusion.

The System Is the True Bottleneck

A seal's temperature rating is meaningless in isolation. The performance of the lubricant, the viscosity of the hydraulic fluid, and the tolerance of other system components will often dictate the true operational temperature limit of the entire assembly.

Making the Right Choice for Your Goal

Selecting the correct seal variant requires matching the material's capability to the specific demands of the environment.

- If your primary focus is a standard industrial application: The baseline range of -54°C to 232°C is more than sufficient and provides a reliable, cost-effective solution.

- If your primary focus is a high-performance system with extreme heat: You must specify a specialized, filled PTFE compound engineered for continuous operation up to 260°C (500°F).

- If your primary focus is a cryogenic or aerospace application: Specialized PTFE is one of the few materials that can maintain seal integrity and flexibility down to -200°C (-328°F).

Ultimately, choosing the right seal is about understanding the full context of your operating environment, not just a single number on a data sheet.

Summary Table:

| Temperature Range | Type of PTFE Seal | Typical Applications |

|---|---|---|

| -54°C to 232°C (-65°F to +450°F) | Standard / Virgin PTFE | Most industrial hydraulic & pneumatic systems |

| -200°C to 260°C (-328°F to +500°F) | Specialized / Filled PTFE Compounds | Cryogenic, aerospace, and high-heat systems |

| Up to 316°C (600°F) | Specialized Compounds (Intermittent Spikes) | Systems with brief thermal excursions |

Don't let temperature extremes compromise your system's integrity.

Your application's specific thermal environment—from cryogenic cold to intense heat—demands a sealing solution engineered for peak performance. The right PTFE compound is critical for reliability.

KINTEK specializes in the precision manufacturing of PTFE components, including seals, liners, and labware. We serve the semiconductor, medical, laboratory, and specialized industrial sectors. Our expertise ensures your seals are not just a component, but a robust, reliable part of your system.

We provide custom fabrication from prototypes to high-volume orders, tailoring the material composition to your exact temperature and performance requirements.

Let's engineer the perfect seal for your environment. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for mechanical seals? Unlock Superior Sealing Performance

- How does low friction benefit mechanical systems using PTFE washers? Boost Efficiency & Lifespan

- What lubrication characteristics does PTFE offer for mechanical seals? Achieve Oil-Free, Low-Friction Sealing

- What metal options are available for the casing of PTFE rotary lip seals? A Guide to Material Selection

- What are the advantages of machining Teflon? Unlock Superior Performance for Critical Components

- Why is resistance to chemical and physical corrosion important for PTFE gasket raw materials? Ensure Long-Term Sealing Reliability

- What are the main applications of PTFE envelope gaskets? Seal Fragile Flanges and Prevent Contamination

- What are common applications of Teflon machined parts? Seals, Bearings & Insulators for Demanding Industries