In short, machined Teflon (PTFE) parts are used in virtually every high-stakes industry where components must withstand extreme conditions. Common applications include critical seals and bearings in aerospace, biocompatible instruments in the medical field, insulators in electronics, and non-reactive components for chemical and food processing. The selection of PTFE is driven by its unique ability to solve problems that other materials cannot.

The core reason for Teflon's widespread use is not a single feature, but its rare combination of four key properties: near-total chemical inertness, an extremely low coefficient of friction, high-temperature stability, and excellent electrical insulation.

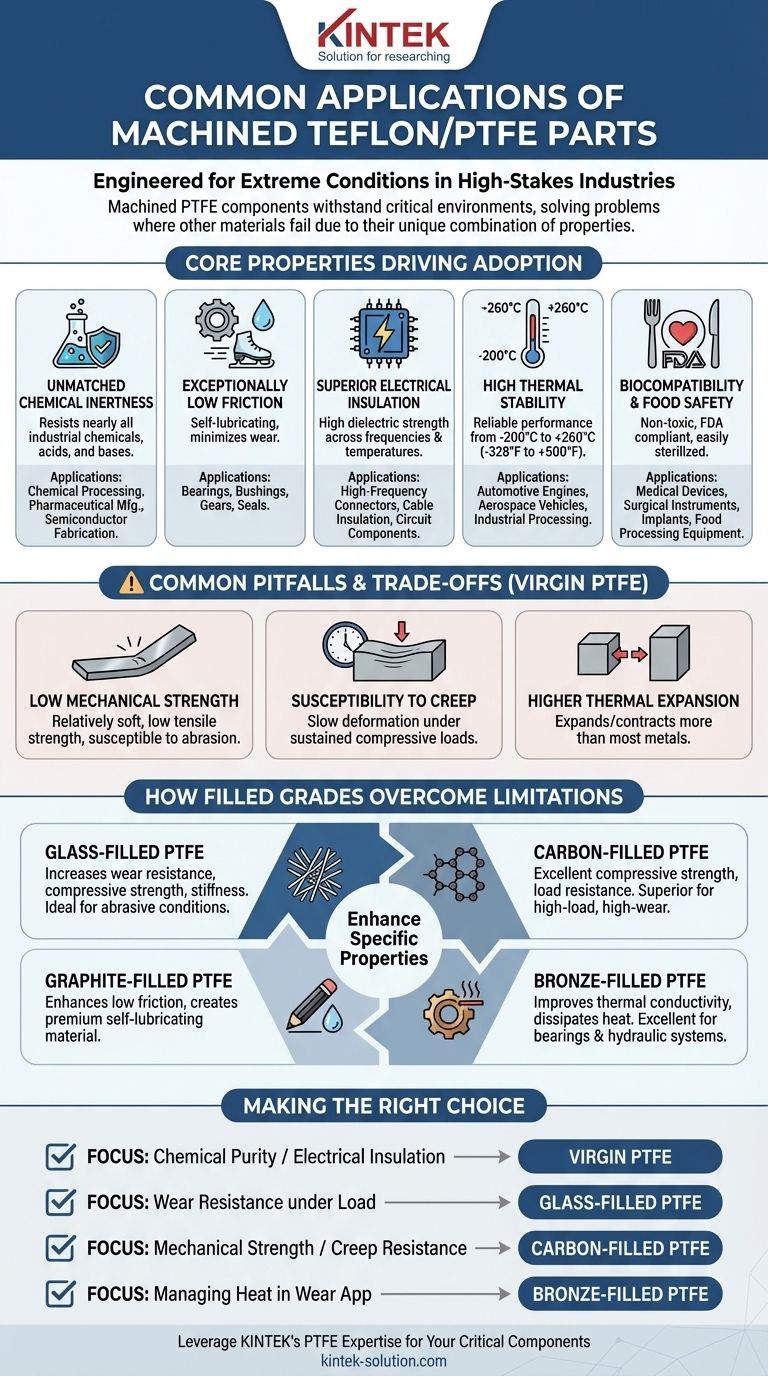

The Core Properties Driving Teflon's Adoption

To understand where Teflon is used, you must first understand why it is chosen. Its value comes from a unique set of material characteristics that make it a premier problem-solving polymer.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. It resists nearly all industrial chemicals, acids, and bases, making it the default choice for handling aggressive or high-purity fluids.

This property is essential for components in chemical processing equipment, pharmaceutical manufacturing, and semiconductor fabrication, where material degradation or contamination is not an option.

Exceptionally Low Coefficient of Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This makes it an ideal self-lubricating material.

This is why it's machined into bearings, bushings, gears, and seals for mechanical, automotive, and aerospace systems where minimizing friction and wear is critical.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with a very high dielectric strength and low dielectric constant. It maintains these properties across a wide range of frequencies and temperatures.

This makes it indispensable for manufacturing high-frequency connectors, cable insulation, and circuit board components in the aerospace and electronics industries.

High Thermal Stability

Standard PTFE performs reliably across a vast temperature range, typically from -200°C to +260°C (-328°F to +500°F). It does not become brittle at low temperatures or melt at high temperatures.

This thermal resilience is crucial for components in automotive engines, aerospace vehicles, and industrial processing environments that experience extreme temperature fluctuations.

Biocompatibility and Food Safety

Virgin PTFE is non-toxic, biocompatible, and compliant with FDA regulations for food contact. It does not support bacterial growth and is easily sterilized.

These traits make it a go-to material for medical devices, surgical instruments, implants, and food processing equipment like gaskets, valves, and non-stick surfaces.

Common Pitfalls and Trade-offs of Virgin PTFE

While its core properties are remarkable, standard (virgin) PTFE is not a perfect material for every situation. Understanding its limitations is key to using it effectively.

Low Mechanical Strength

Compared to engineering metals or even other polymers, virgin PTFE is relatively soft. It has low tensile strength and is susceptible to abrasion from sharp or hard particles.

Susceptibility to Creep

Under sustained compressive loads, PTFE can exhibit "creep" or cold flow. This means the material can slowly deform over time, which can be a problem for high-load structural applications.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals. This must be accounted for in the design of tight-tolerance assemblies to prevent parts from seizing or failing.

How Filled Grades Overcome Limitations

To address the mechanical weaknesses of virgin PTFE, a wide range of "filled" compounds have been developed. These grades blend PTFE with other materials to enhance specific properties.

Glass-Filled PTFE

Adding 15-25% glass fiber dramatically increases wear resistance, compressive strength, and stiffness. This is a common choice for bearings and seals that need to withstand abrasive conditions.

Carbon-Filled PTFE

Blending 25-35% carbon provides excellent compressive strength and load resistance, making it superior for applications requiring high mechanical strength and wear performance, such as piston rings.

Graphite-Filled PTFE

A small amount of graphite (around 15%) enhances PTFE's already low coefficient of friction, creating a premium self-lubricating material for low-friction, high-speed applications.

Bronze-Filled PTFE

Adding 40-60% bronze significantly improves thermal conductivity, allowing heat to dissipate away from wear surfaces. This grade also has excellent wear resistance and is often used for bearings and hydraulic systems.

Making the Right Choice for Your Application

Selecting the correct grade of Teflon is about matching the material's strengths to your primary engineering challenge.

- If your primary focus is chemical purity or electrical insulation: Virgin PTFE is the definitive choice for its unmatched inertness and dielectric properties.

- If your primary focus is wear resistance under load: Glass-filled PTFE provides the necessary durability and strength for demanding seals and bearings.

- If your primary focus is mechanical strength and creep resistance: Carbon-filled PTFE offers the best performance for high-load applications like piston rings and structural components.

- If your primary focus is managing heat in a wear application: Bronze-filled PTFE is the ideal solution due to its superior thermal conductivity.

Ultimately, understanding the unique material science behind Teflon empowers you to leverage it as a powerful solution for your most demanding engineering problems.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals | Chemical processing, semiconductor, pharmaceutical components |

| Low Friction | Self-lubricating, reduces wear | Bearings, bushings, seals, gears |

| Electrical Insulation | High dielectric strength | High-frequency connectors, circuit boards |

| Thermal Stability | Performs from -200°C to +260°C | Automotive, aerospace, and industrial components |

| Biocompatibility | FDA compliant, non-toxic | Medical devices, surgical tools, food processing equipment |

Leverage KINTEK's PTFE Expertise for Your Critical Components

Are you designing for extreme conditions in the semiconductor, medical, laboratory, or industrial sectors? KINTEK specializes in manufacturing precision-machined PTFE components—from custom seals and liners to complex labware—that meet the highest standards for chemical resistance, thermal stability, and performance.

We combine expert material science with advanced fabrication capabilities to deliver solutions from prototypes to high-volume production runs. Whether you need the pure chemical resistance of virgin PTFE or the enhanced strength of a filled grade, our team will help you select the optimal material for your application.

Contact KINTEK today to discuss your project requirements and receive a quote for custom PTFE parts that solve your most demanding engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining