At its core, a PTFE Teflon O-ring is defined by its exceptional resilience in extreme conditions. It is a specialty sealing material valued for its near-universal chemical resistance, performance across an incredibly wide temperature range, extremely low friction, and excellent dielectric properties. Unlike traditional rubber O-rings, its primary strengths lie in its chemical and thermal stability rather than its elasticity.

While often categorized with rubber O-rings, PTFE Teflon is fundamentally different. Its value lies not in its elasticity, but in its unparalleled chemical, thermal, and electrical resistance, making it a specialized sealing solution for environments where conventional elastomers would fail.

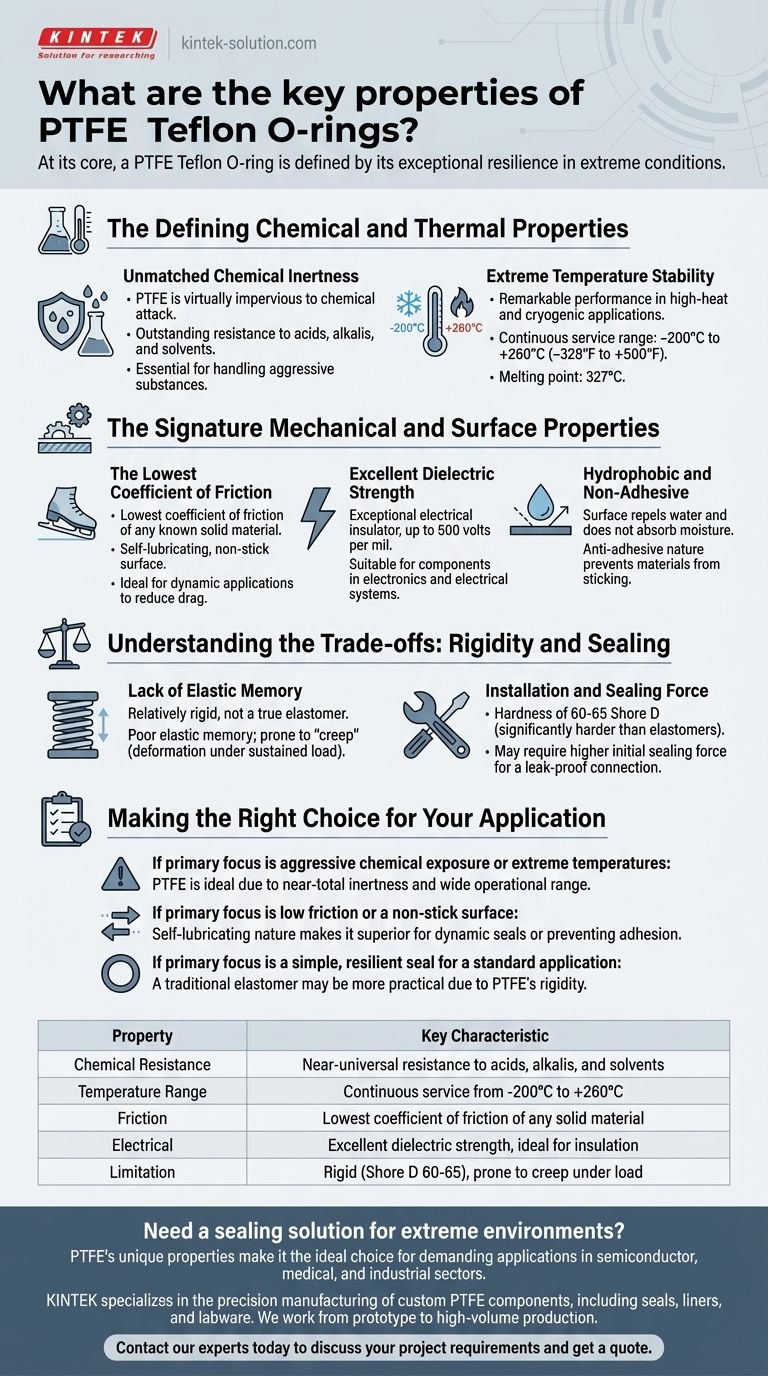

The Defining Chemical and Thermal Properties

The foundation of PTFE's performance stems from the powerful carbon-fluorine bonds that make up its molecular structure. These bonds create a material that is uniquely stable and non-reactive.

Unmatched Chemical Inertness

PTFE is virtually impervious to chemical attack. It exhibits outstanding resistance to almost all industrial chemicals, solvents, acids, and alkalis, making it an essential material for processing and handling aggressive substances.

Extreme Temperature Stability

This material demonstrates remarkable performance in both high-heat and cryogenic applications. PTFE can withstand a continuous service temperature range from –200°C to +260°C (–328°F to +500°F), with a high melting point of 327°C.

The Signature Mechanical and Surface Properties

Beyond its stability, PTFE's physical characteristics make it a unique problem-solver for specific mechanical and electrical challenges.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material. This results in a self-lubricating, non-stick surface that is ideal for dynamic applications where reducing drag and preventing seizure is critical.

Excellent Dielectric Strength

With the ability to insulate up to 500 volts per mil, PTFE is an exceptional electrical insulator. This property, combined with its heat resistance, makes it highly suitable for components in electronics and electrical systems.

Hydrophobic and Non-Adhesive

The surface of PTFE is hydrophobic, meaning it repels water and does not absorb moisture. Its anti-adhesive nature also prevents other materials from sticking to it, which is crucial for applications in food processing, medical devices, and manufacturing.

Understanding the Trade-offs: Rigidity and Sealing

While its properties are exceptional, PTFE is not a universal replacement for rubber O-rings. Its primary limitations are a direct result of its unique physical structure.

Lack of Elastic Memory

PTFE is a relatively rigid material, not a true elastomer. It has poor elastic memory, meaning that once compressed, it does not spring back to its original shape as effectively as rubber. This can lead to deformation under sustained load, a phenomenon known as "creep."

Installation and Sealing Force

With a hardness of 60-65 Shore D, PTFE is significantly harder than typical elastomers (which are measured on the softer Shore A scale). This rigidity can make installation challenging and often requires a higher initial sealing force to ensure a leak-proof connection.

Making the Right Choice for Your Application

Selecting PTFE depends entirely on whether your application demands its unique strengths and can accommodate its mechanical limitations.

- If your primary focus is aggressive chemical exposure or extreme temperatures: PTFE is likely the ideal choice due to its near-total inertness and wide operational range.

- If your primary focus is low friction or a non-stick surface: The self-lubricating nature of PTFE makes it superior for dynamic seals or applications where material adhesion is a problem.

- If your primary focus is a simple, resilient seal for a standard application: A traditional elastomer like Nitrile or Viton may be a more practical and cost-effective solution due to PTFE's inherent rigidity.

Ultimately, understanding PTFE's unique profile as a high-performance specialty material is the key to deploying it effectively in demanding engineering challenges.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Chemical Resistance | Near-universal resistance to acids, alkalis, and solvents |

| Temperature Range | Continuous service from -200°C to +260°C (-328°F to +500°F) |

| Friction | Lowest coefficient of friction of any solid material |

| Electrical | Excellent dielectric strength, ideal for insulation |

| Limitation | Rigid (Shore D 60-65), prone to creep under load |

Need a sealing solution for extreme environments?

PTFE's unique properties make it the ideal choice for demanding applications in the semiconductor, medical, laboratory, and industrial sectors where chemical resistance, extreme temperatures, or low friction are critical.

KINTEK specializes in the precision manufacturing of custom PTFE components, including seals, liners, and labware. We work with you from prototype to high-volume production to ensure a perfect fit and superior performance for your specific challenge.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry