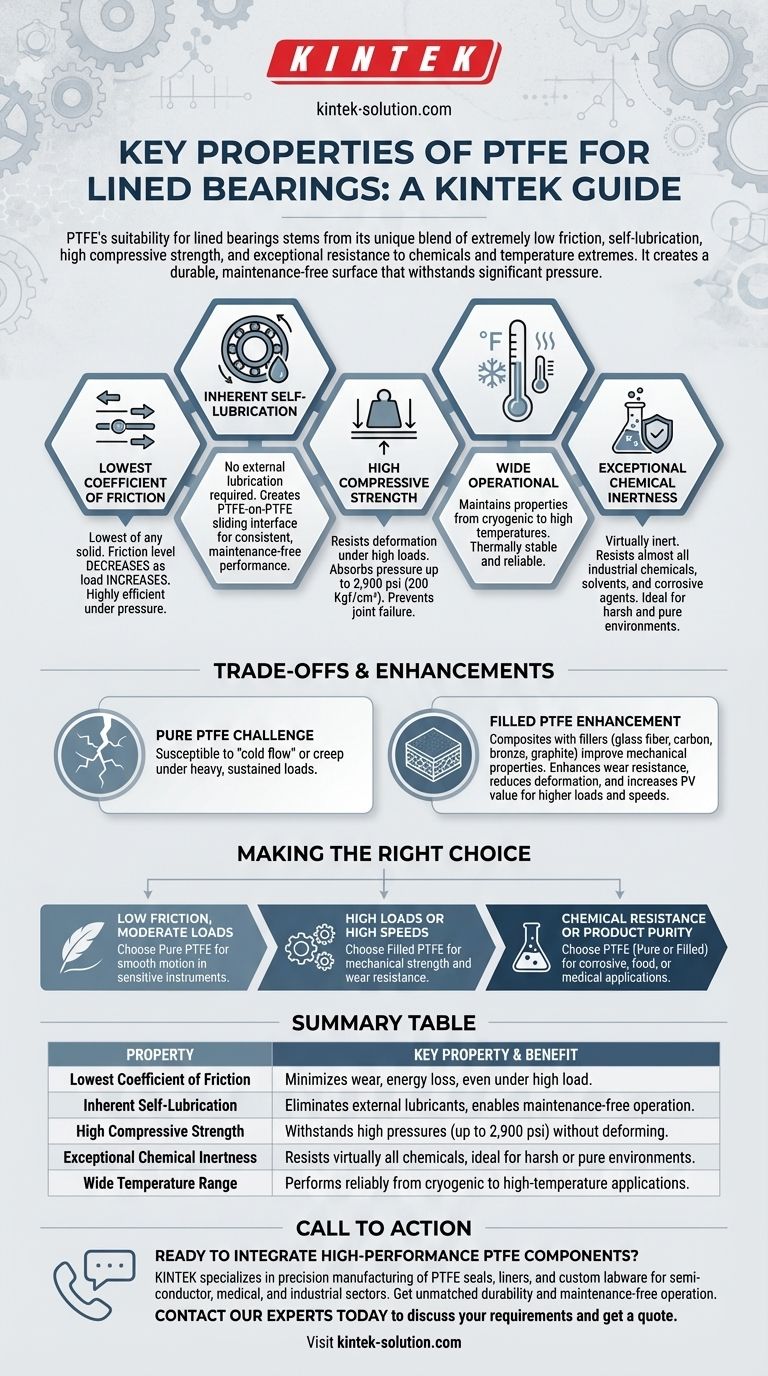

At its core, the suitability of Polytetrafluoroethylene (PTFE) for lined bearings comes from its unique combination of an extremely low coefficient of friction, inherent self-lubricating capabilities, and high compressive strength. These primary traits are further supported by its exceptional resistance to chemicals and its ability to function across a wide range of temperatures.

A bearing's fundamental purpose is to minimize friction and wear between moving parts. PTFE achieves this not just by being slippery, but by creating a durable, maintenance-free surface that can withstand significant pressure without requiring external liquid lubricants like oil or grease.

The Core Properties of PTFE in Detail

To understand why PTFE is a default choice for high-performance bearings, we must look at how its individual characteristics work together.

The Lowest Coefficient of Friction

PTFE possesses the lowest coefficient of friction of any known solid material. This is its most well-known attribute.

Critically, this friction level is not static. As the load on the bearing increases, the coefficient of friction often decreases, meaning it becomes even more efficient under pressure.

Inherent Self-Lubrication

PTFE-lined bearings do not require external lubrication. During the initial "run-in" period, an imperceptibly thin layer of PTFE transfers from the liner to the mating shaft surface.

This process creates a highly effective PTFE-on-PTFE sliding interface, which is the mechanism behind its self-lubrication and consistent performance over the bearing's lifespan.

High Compressive Strength

A bearing liner must resist being squeezed out of place. PTFE has excellent compressive strength, capable of absorbing pressures up to 2,900 psi (200 Kgf/cm²).

This robustness ensures the liner maintains its integrity under significant static and dynamic loads, preventing joint failure.

Wide Operational Temperature Range

PTFE maintains its key properties across an exceptionally broad spectrum of temperatures.

This thermal stability makes it a reliable choice for applications ranging from cryogenic equipment to high-temperature industrial machinery without becoming brittle or degrading.

Exceptional Chemical Inertness

PTFE is virtually inert, resisting attack from almost all industrial chemicals, solvents, and corrosive agents.

This makes PTFE-lined bearings ideal for use in harsh chemical processing environments. It also ensures they are safe for food-grade and medical applications where contamination is not an option.

Understanding the Trade-offs and Enhancements

While pure PTFE is remarkable, it is not without limitations. Understanding these trade-offs is crucial for correct application.

The Challenge of Pure PTFE

Under heavy, sustained loads, pure PTFE can be susceptible to "cold flow," or creep, where the material slowly deforms over time. This can limit its use in very high-load applications.

The Role of Fillers

To counteract this, manufacturers create "filled PTFE" composites. Materials like glass fiber, carbon, bronze, or graphite are blended into the PTFE.

These fillers act as a reinforcing matrix, dramatically improving the mechanical properties of the base material.

Improving Performance with Filled PTFE

Fillers significantly enhance wear resistance, reduce deformation under load, and increase the bearing's PV value (Pressure-Velocity limit).

A higher PV value means the bearing can withstand much greater loads and higher rotational speeds, expanding its operational envelope far beyond what pure PTFE could handle.

Making the Right Choice for Your Application

Selecting the right type of PTFE bearing liner depends entirely on the specific demands of your design.

- If your primary focus is low-friction, smooth motion in moderate load conditions: Pure PTFE offers an unmatched slick surface ideal for sensitive instruments or components.

- If your primary focus is handling high loads or high speeds: A filled PTFE composite is necessary to provide the required mechanical strength and wear resistance.

- If your primary focus is chemical resistance or product purity: PTFE, in either pure or filled form, is the definitive choice for applications in corrosive environments or the food and medical industries.

Ultimately, selecting a PTFE-lined bearing is a decision to prioritize reliability and maintenance-free performance across a vast range of demanding conditions.

Summary Table:

| Key Property | Benefit for Lined Bearings |

|---|---|

| Lowest Coefficient of Friction | Minimizes wear and energy loss, even under high load. |

| Inherent Self-Lubrication | Eliminates the need for external lubricants, enabling maintenance-free operation. |

| High Compressive Strength | Withstands high pressures (up to 2,900 psi) without deforming. |

| Exceptional Chemical Inertness | Resists virtually all chemicals, ideal for harsh or pure environments. |

| Wide Temperature Range | Performs reliably from cryogenic to high-temperature applications. |

Ready to integrate high-performance PTFE components into your design?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype for testing or a high-volume production run, our expertise ensures you get a bearing solution that delivers unmatched durability and maintenance-free operation.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability