At its core, Polytetrafluoroethylene, or PTFE, is most commonly known by its trademarked name, Teflon. While its reputation was built on creating non-stick surfaces for cookware, its true value lies in a unique set of properties that make it an essential material across demanding industries, from aerospace to chemical processing.

PTFE is not just a coating for pans; it is a high-performance fluoropolymer prized for its unrivaled combination of chemical inertness, low friction, and thermal stability. This unique blend of characteristics makes it a critical problem-solving material in applications where other plastics would fail.

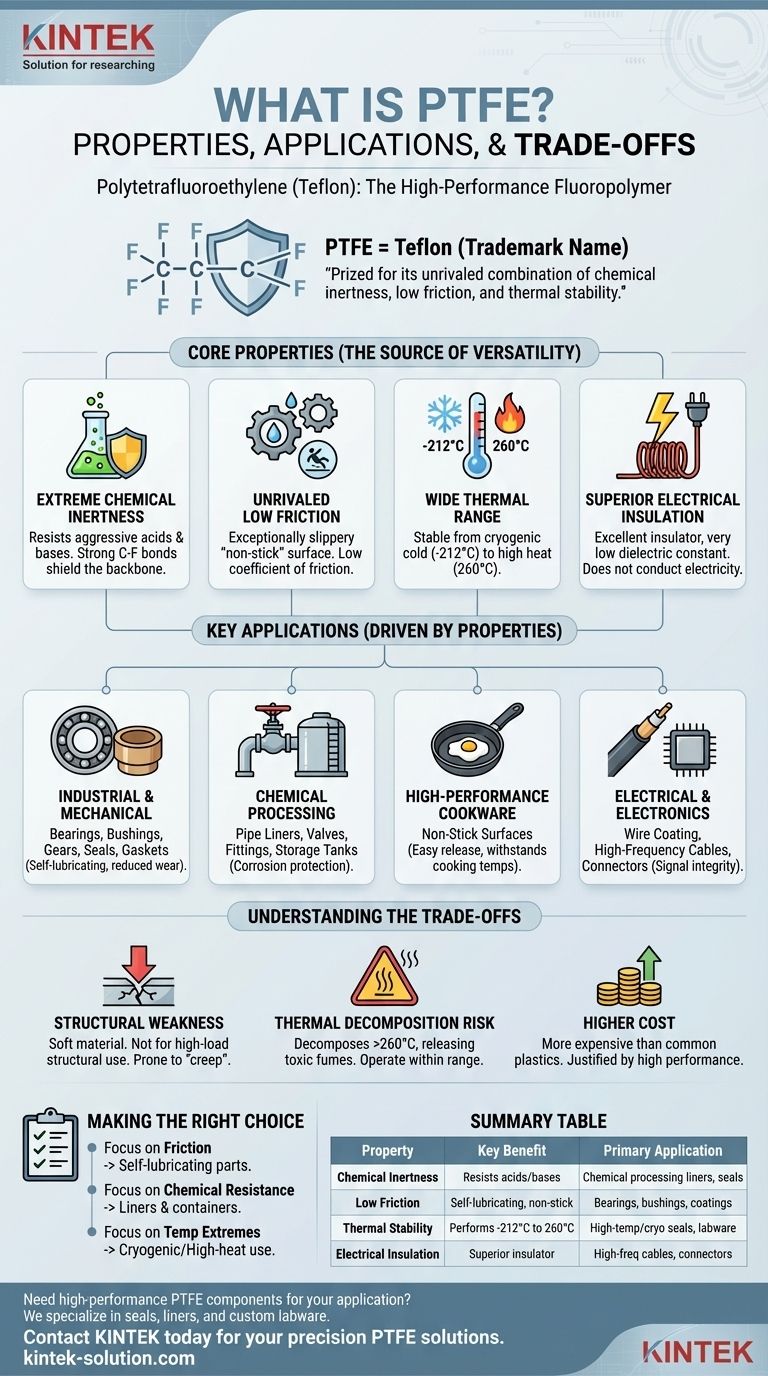

The Source of Its Versatility: Core Properties

To understand why PTFE is so widely used, you must first understand its fundamental characteristics. Its applications are a direct result of its unique molecular structure, which is composed of only carbon and fluorine atoms.

Extreme Chemical Inertness

PTFE is one of the most non-reactive substances known. It is highly resistant to a vast range of chemicals, including aggressive acids and bases.

This property stems from the very strong bonds between carbon and fluorine atoms, which shield the carbon backbone from chemical attack.

Unrivaled Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it an exceptionally slippery or "non-stick" surface.

This is why materials, including water and oil, do not readily adhere to it, a property useful in both cookware and industrial machinery.

Wide Thermal Range

This material demonstrates remarkable stability across a huge range of temperatures.

It remains flexible and functional at cryogenic temperatures as low as -212°C (-350°F) and can be used continuously at temperatures up to 260°C (500°F).

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a very low dielectric constant. It does not conduct electricity and resists high voltages.

This makes it an ideal material for insulating high-frequency cables and connectors where signal integrity is paramount.

Key Applications Driven by Properties

The true scope of PTFE's utility becomes clear when you see how its core properties are leveraged to solve specific engineering challenges.

Industrial and Mechanical Components

Due to its low friction, PTFE is machined into parts that require smooth, sliding action with no external lubrication.

Common examples include bearings, bushings, gears, and slide plates where it reduces wear and improves efficiency. Its flexibility and chemical resistance also make it a superior material for seals and gaskets.

Chemical Processing and Containment

Its extreme chemical resistance makes PTFE the default choice for handling corrosive substances.

It is widely used as a liner for pipes, valves, fittings, and storage tanks in chemical plants, protecting the structural metal from damage.

High-Performance Cookware

This is PTFE's most famous application. Its non-stick surface and ability to withstand cooking temperatures allow for easy food release and cleanup.

The combination of low friction and thermal stability is what makes a "non-stick pan" possible.

Electrical and Electronics

As a superior insulator, PTFE is used to coat wires and manufacture high-performance coaxial cables.

Its reliability in extreme temperatures also makes it suitable for aerospace and computer applications where performance cannot be compromised.

Understanding the Trade-offs

No material is perfect. While PTFE has exceptional properties, it's crucial to understand its limitations to use it effectively.

Structural Weakness

PTFE is a relatively soft material. It is not suitable for high-load structural applications, as it can deform under constant pressure, a phenomenon known as "creep."

Thermal Decomposition Risk

While stable up to 260°C (500°F), PTFE will begin to decompose at significantly higher temperatures. This decomposition can release toxic fumes.

It is critical to operate within its specified temperature range to ensure safety, particularly in consumer applications like cookware.

Higher Cost

As a high-performance polymer, PTFE is more expensive than common plastics like polyethylene or polypropylene. Its use is typically justified by performance requirements that commodity plastics cannot meet.

Making the Right Choice for Your Goal

Your choice of material depends entirely on the problem you are trying to solve. PTFE is a specialized solution for demanding conditions.

- If your primary focus is reducing friction: PTFE is the benchmark for creating self-lubricating parts like bearings, seals, and low-friction coatings.

- If your primary focus is chemical resistance: PTFE is the industry standard for lining pipes, valves, and containers that handle highly corrosive materials.

- If your primary focus is performance across extreme temperatures: PTFE provides reliable service in both cryogenic cold and high-heat environments where other materials would become brittle or degrade.

Ultimately, PTFE's value lies in its ability to perform reliably where other materials simply cannot.

Summary Table:

| Property | Key Benefit | Primary Application |

|---|---|---|

| Chemical Inertness | Resists aggressive acids/bases | Chemical processing liners, seals |

| Low Friction | Self-lubricating, non-stick | Bearings, bushings, non-stick coatings |

| Thermal Stability | Performs from -212°C to 260°C | High-temp/cryogenic seals, labware |

| Electrical Insulation | Superior insulator, low dielectric constant | High-frequency cables, connectors |

Need high-performance PTFE components for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our custom fabrication ensures your components meet the demanding requirements for chemical resistance, thermal stability, and low friction.

Contact us today to discuss how our PTFE solutions can enhance your project's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How is PTFE processed after suspension polymerization? From Raw Polymer to Industrial-Grade Material

- How does the low surface energy of PTFE contribute to its properties? Unlock Non-Stick, Low-Friction Performance

- What PTFE formulations are recommended for automotive and aerospace applications and why? Optimize with Bronze-Filled PTFE

- What are some notable properties of PTFE? Discover the Extreme Performance of Teflon

- How does PTFE improve operational efficiency in machinery? Reduce Energy, Downtime & Costs

- What are the notable physical and chemical properties of PTFE? Master Its Unique Strengths and Limitations

- What is PTFE commonly known as and when was it developed? The 'Plastics King' for Extreme Performance

- What certifications does the manufacturer of PTFE products hold? The ISO 9001 Assurance for Quality