At its core, Polytetrafluoroethylene (PTFE) improves operational efficiency in machinery by creating an extremely low-friction environment. This fundamental property drastically reduces the energy required to operate moving parts, which in turn minimizes wear, lowers maintenance needs, and allows equipment to perform reliably under more demanding conditions.

The true value of PTFE isn't just its slipperiness; it's a strategic engineering choice that translates a low coefficient of friction into tangible outcomes: lower energy bills, longer component life, and significantly less downtime.

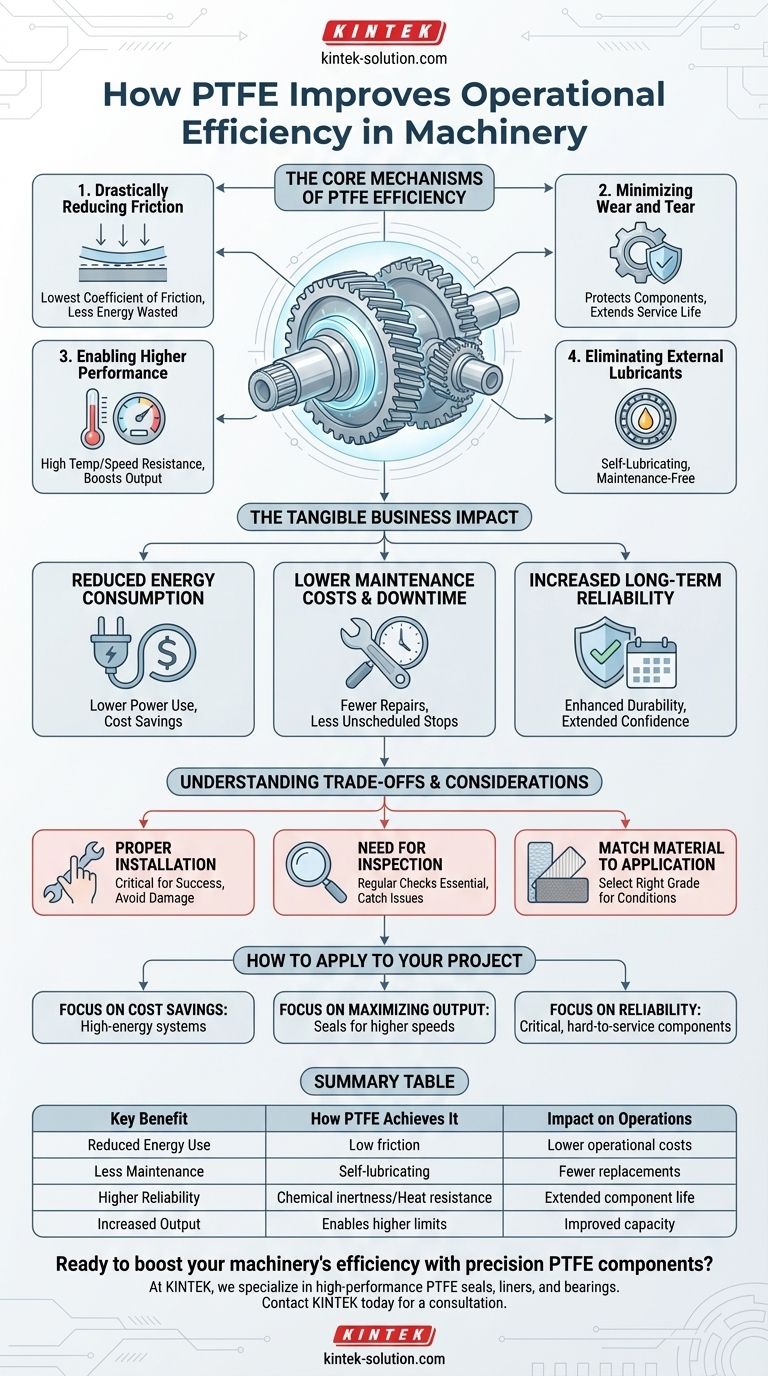

The Core Mechanisms of PTFE Efficiency

Understanding how PTFE works reveals its impact on the entire operational lifecycle of a machine. Its benefits stem from a few key physical properties that have an outsized effect on performance and durability.

Drastically Reducing Friction

PTFE has one of the lowest coefficients of friction of any solid material. When used in components like seals, washers, and liners, it creates a surface that requires minimal force to move against another part.

This inherent lubricity means less energy is wasted overcoming resistance, leading to smoother, more efficient mechanical operation.

Minimizing Wear and Tear

Friction is the primary cause of wear in machinery. By reducing it so effectively, PTFE components protect both themselves and the parts they contact, such as shafts and gears.

This significant reduction in wear directly extends the service life of critical components, preserving the integrity of the machine for longer periods.

Enabling Higher Performance

PTFE's chemical inertness and high-temperature resistance allow it to function where traditional materials would fail. This enables machinery to be pushed to higher speeds and temperatures without compromising seal integrity or component function.

The result is a direct boost in productivity and output, as the equipment can operate closer to its maximum design potential.

Eliminating External Lubricants

In many applications, PTFE components like washers and bearings are self-lubricating. They can function perfectly without the need for grease or oil.

This creates maintenance-free solutions that are ideal for clean environments or hard-to-reach parts, simplifying design and eliminating a common point of failure and contamination.

The Tangible Business Impact

The physical properties of PTFE translate directly into measurable improvements in cost, reliability, and overall operational effectiveness.

Reduced Energy Consumption

Less friction means less power is needed to drive the machinery. This reduction in energy consumption leads to direct cost savings on electricity or fuel and contributes to a lower environmental impact.

Lower Maintenance Costs and Downtime

Because PTFE extends the life of seals, bearings, and other moving parts, the need for frequent replacement and repair is dramatically reduced.

This means fewer planned maintenance cycles and, more importantly, a lower risk of unscheduled downtime, which is often the single largest cost in an industrial setting.

Increased Long-Term Reliability

By mitigating the primary causes of mechanical failure—friction and wear—PTFE enhances the overall durability of equipment. Machinery can operate reliably for extended periods, even under continuous or extreme conditions.

This long-term reliability allows manufacturers to offer extended warranties and provides operators with greater confidence in their equipment.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. Achieving its full benefits requires proper implementation and awareness of its operational context.

The Importance of Proper Installation

The performance of any PTFE component is highly dependent on correct installation. This includes meticulous surface preparation and using the right techniques to avoid damaging the material.

An improperly installed seal or bearing will fail prematurely, negating all of its potential benefits.

The Need for Inspection

While PTFE can create "maintenance-free" solutions, it does not eliminate the need for regular inspection. Visual checks for wear, damage, or changes in performance are critical to ensuring long-term reliability and catching potential issues early.

Matching the Material to the Application

PTFE comes in various grades and composites, each designed for specific pressures, temperatures, and chemical environments. Selecting the wrong type can lead to poor performance.

It is crucial to ensure the specific PTFE component is engineered to handle the unique operational conditions of your machinery.

How to Apply This to Your Project

Your specific goal will determine which benefit of PTFE is most valuable to your operation.

- If your primary focus is cost savings: Prioritize PTFE components in high-energy systems to capitalize on reduced power consumption and lower maintenance expenses.

- If your primary focus is maximizing output: Use PTFE seals and bearings to push machinery to higher speeds and temperatures, increasing your production capacity.

- If your primary focus is long-term reliability: Implement PTFE in critical, hard-to-service components to minimize wear and dramatically reduce the risk of unscheduled downtime.

Ultimately, integrating PTFE into your machinery is an investment in sustained operational excellence.

Summary Table:

| Key Benefit | How PTFE Achieves It | Impact on Operations |

|---|---|---|

| Reduced Energy Use | Extremely low coefficient of friction | Lower power consumption & operational costs |

| Less Maintenance | Self-lubricating; minimizes wear on parts | Fewer replacements & reduced downtime |

| Higher Reliability | Chemical inertness & high-temperature resistance | Extended component life in harsh conditions |

| Increased Output | Enables higher speeds & temperatures | Improved productivity & capacity |

Ready to boost your machinery's efficiency with precision PTFE components?

At KINTEK, we specialize in manufacturing high-performance PTFE seals, liners, bearings, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Our components are engineered to reduce your energy costs, minimize downtime, and extend equipment life—delivering tangible operational savings and reliability.

Whether you need prototypes or high-volume orders, our custom fabrication ensures a perfect fit for your unique application requirements.

Contact KINTEK today for a consultation and see how our PTFE solutions can optimize your operations!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems