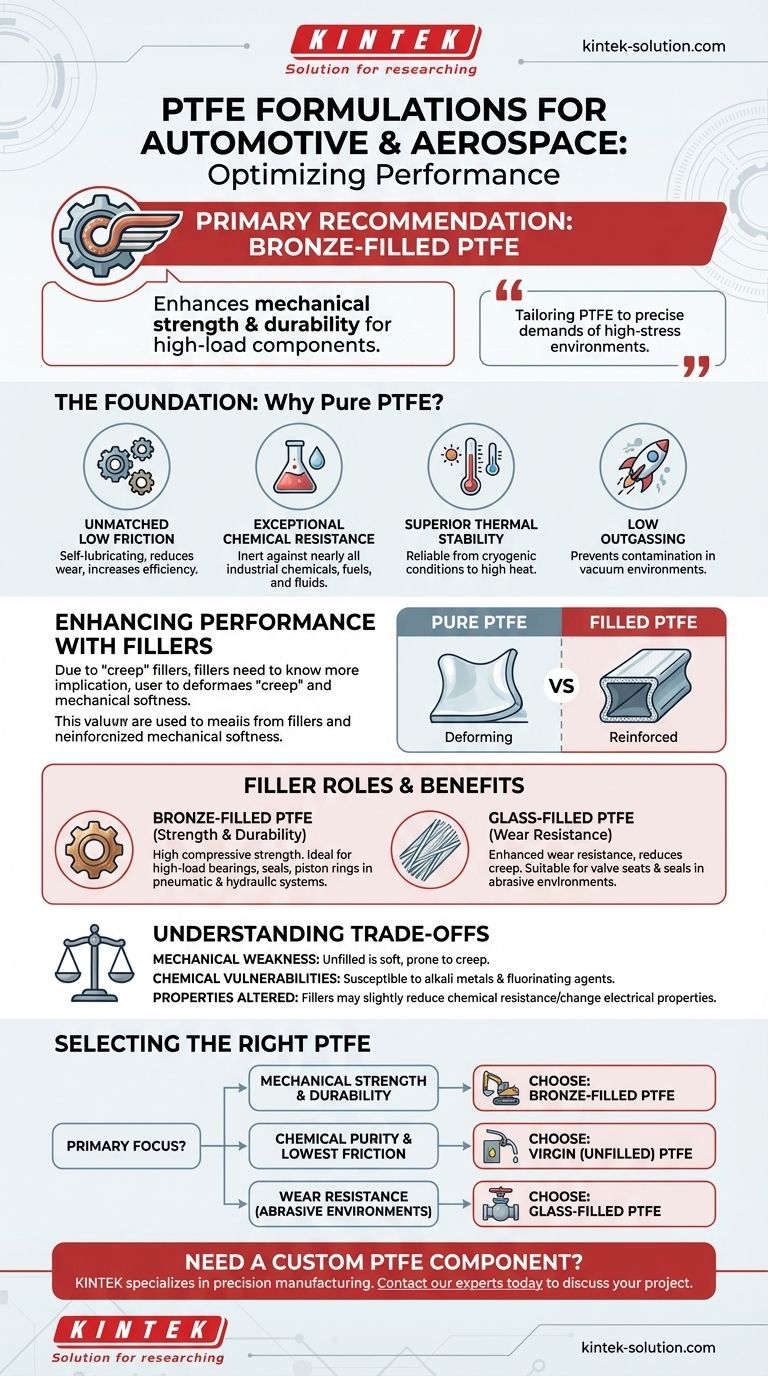

For automotive and aerospace applications, bronze-filled PTFE is a primary recommendation due to its significantly enhanced mechanical strength and durability. While pure PTFE provides the foundational benefits of low friction and chemical resistance, adding bronze filler addresses its inherent softness, making it robust enough for high-load components like bearings and seals in pneumatic and hydraulic systems.

The core decision is not simply choosing PTFE, but selecting a formulation where specific fillers are used to overcome the mechanical limitations of pure PTFE, tailoring it to the precise demands of high-stress automotive and aerospace environments.

The Foundation: Why Pure PTFE is the Starting Point

Before considering fillers, it's essential to understand the inherent properties that make Polytetrafluoroethylene (PTFE) a candidate material for these demanding industries in the first place.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. It is self-lubricating, which is critical for components that must operate without external lubrication or in dry-running conditions.

This property reduces wear on moving parts, lowers power requirements, and increases the overall efficiency of mechanical systems like bearings and sliding joints.

Exceptional Chemical Resistance

PTFE is chemically inert and non-soluble against nearly all industrial chemicals. This makes it invaluable for handling aggressive media common in these sectors.

It reliably resists degradation from jet fuels, hydraulic fluids, and powerful degreasers, preventing material failure and contamination of sensitive systems.

Superior Thermal Stability

Components in engines and aerospace systems must endure extreme temperature fluctuations. PTFE maintains its integrity and properties across a very wide temperature range.

This thermal resistance ensures reliable performance in both cryogenic conditions and high-heat environments, from deep space to next-generation engine compartments.

Low Outgassing for Space

In the vacuum of space, materials can release trapped gasses in a process called outgassing. These gasses can contaminate sensitive optical and electronic equipment.

PTFE naturally exhibits very low outgassing, making it a trusted material for components used in satellites and other spacecraft.

Enhancing Performance with Fillers

While pure (or "virgin") PTFE has exceptional properties, it is mechanically soft and can deform under load, a phenomenon known as "creep." Fillers are added to the PTFE matrix to improve these mechanical characteristics.

The Role of Fillers

Fillers are microscopic particles of other materials, such as bronze, glass, or carbon, blended with PTFE resin before it is processed. Each filler imparts specific properties to the final material.

Bronze-Filled PTFE: The Go-To for Strength

Bronze is the most common filler for automotive and aerospace applications requiring high mechanical performance.

Adding bronze significantly increases compressive strength and durability. This makes the material suitable for high-load bearings, piston rings, and seals within powerful hydraulic and pneumatic systems where pure PTFE would fail.

Glass-Filled PTFE: A Focus on Wear Resistance

While more common in the chemical processing industry, glass fiber is another important filler.

It primarily enhances wear resistance and reduces creep. This formulation is chosen when the part is subjected to abrasive conditions but does not require the same high-end compressive strength as a bronze-filled component.

Understanding the Trade-offs and Limitations

Selecting the right material requires an objective understanding of its potential downsides. No material is perfect, and PTFE is no exception.

Mechanical Weakness is the Core Issue

The primary reason fillers are necessary is that unfilled PTFE is mechanically weak. It has poor resistance to creep and abrasion, making it unsuitable for many structural or high-pressure applications on its own.

Chemical Vulnerabilities

Despite its broad chemical resistance, PTFE does have a known weakness. It is susceptible to attack by alkali metals and some highly reactive fluorinating agents.

Fillers Can Alter Core Properties

Adding a filler is always a trade-off. For example, while bronze dramatically improves strength, it can slightly reduce the overall chemical resistance and change the electrical properties of the composite compared to virgin PTFE.

Formulation vs. Fabrication

It's important to distinguish the material formulation (e.g., bronze-filled PTFE) from the fabrication method (e.g., CNC machining). The formulation dictates the material's properties, while machining ensures the final part meets precise dimensional tolerances required for aerospace components.

Selecting the Right PTFE for Your Application

Your final choice depends entirely on the specific performance requirements of the component you are designing.

- If your primary focus is mechanical strength and durability: Choose a bronze-filled PTFE for high-load bearings, hydraulic seals, and compressor rings.

- If your primary focus is chemical purity and the lowest friction: Use virgin (unfilled) PTFE for components like fuel system liners or low-load sliding parts where mechanical stress is not a concern.

- If your primary focus is wear resistance in an abrasive environment: Consider a glass-filled PTFE for applications like valve seats and certain types of seals.

By matching the specific enhancements offered by fillers to your application's unique demands, you can leverage the full potential of PTFE for mission-critical systems.

Summary Table:

| Formulation | Key Properties | Ideal Applications |

|---|---|---|

| Bronze-Filled PTFE | High compressive strength, durability, wear resistance | High-load bearings, hydraulic/pneumatic seals, piston rings |

| Virgin (Unfilled) PTFE | Lowest friction, chemical inertness, low outgassing | Fuel system liners, low-load sliding parts, space components |

| Glass-Filled PTFE | Enhanced wear resistance, reduced creep | Valve seats, seals in abrasive environments |

Need a custom PTFE component for a demanding application?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly tailored to your performance requirements, whether you need the strength of bronze-filled PTFE or the purity of virgin PTFE.

Contact our experts today to discuss your project and get a quote.

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- How does PTFE perform in chemically corrosive environments? Unmatched Chemical Immunity & Reliability

- How do PTFE-lined valves prevent leakage and contamination? Ensure Purity and Protect Equipment

- How does PTFE behave in terms of chemical inertness? Unmatched Resistance for Demanding Applications