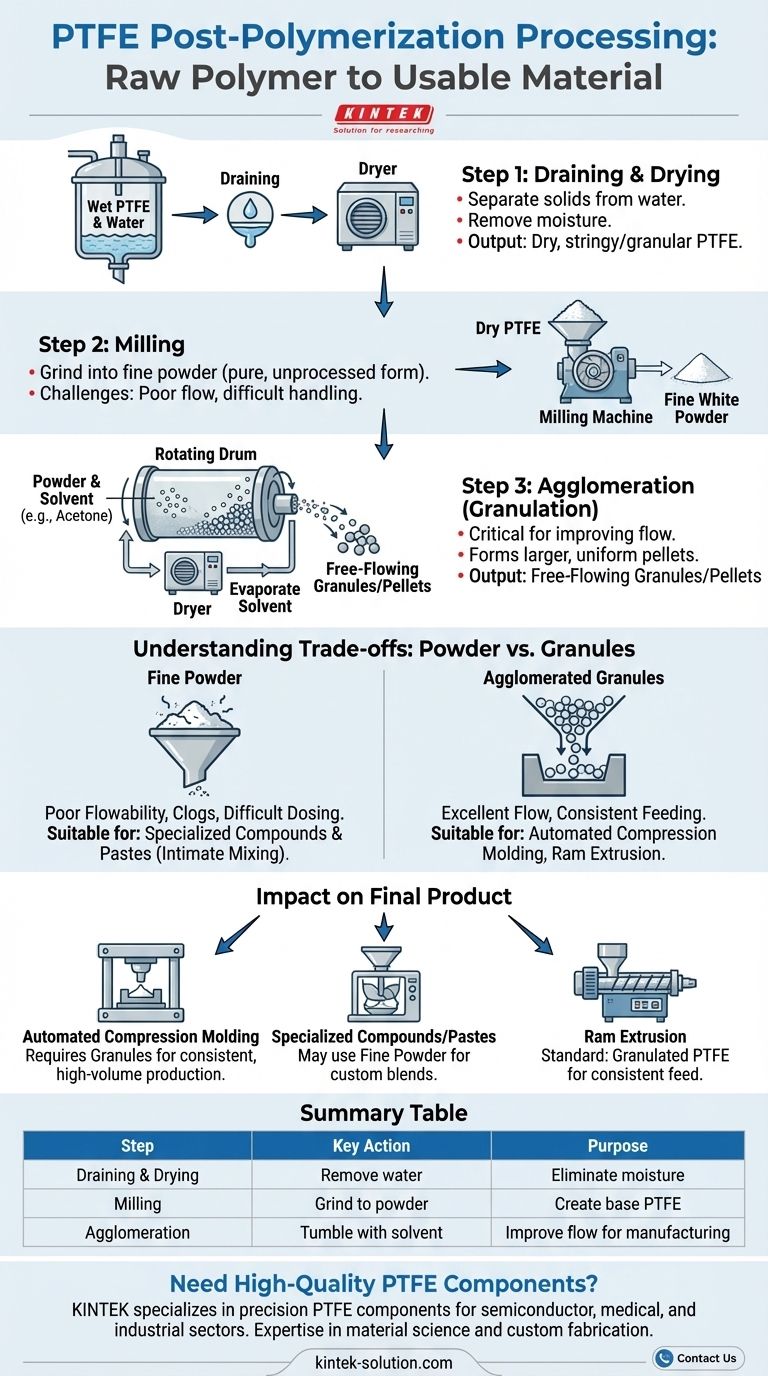

Immediately following suspension polymerization, the raw Polytetrafluoroethylene (PTFE) undergoes a multi-step finishing process. The wet, stringy, or granular material is first dried, then milled into a fine powder, and finally agglomerated into larger, more manageable granules or pellets for industrial use.

The core challenge with raw PTFE powder is its extremely poor flow characteristics, which make it difficult to handle and process. Therefore, the post-polymerization steps are primarily designed to transform this fine powder into a form suitable for common manufacturing techniques like compression molding.

The Journey from Raw Polymer to Usable Material

The steps taken after polymerization are critical to making PTFE a viable industrial material. The process refines the raw polymer into a consistent and predictable feedstock for manufacturers.

Step 1: Draining and Drying

The initial output of suspension polymerization is a mixture of solid PTFE grains and water. The first and most straightforward step is to separate them.

The water is drained from the reaction chamber, leaving behind the solid PTFE. This material, which can be stringy or granular, is then thoroughly dried to remove any residual moisture.

Step 2: Milling into Fine Powder

Once dry, the PTFE is milled. This mechanical process grinds the material into a fine, white powder.

This powder, often compared in appearance to wheat flour, represents the pure, unprocessed form of PTFE. However, this form presents significant handling challenges.

Step 3: Agglomeration (Granulation)

This is the most critical post-processing step, designed to solve the poor flow properties of the fine powder. The powder is agglomerated into larger particles or granules.

A common method involves mixing the powder with a solvent, such as acetone, and tumbling the mixture in a large rotating drum. This action causes the fine particles to stick together, forming larger, more uniform pellets.

After the pellets reach the desired size, they are dried again to evaporate the solvent, leaving behind a free-flowing granular material ready for processing.

Understanding the Trade-offs: Powder vs. Granules

The decision to use fine powder directly or to process it into granules involves a clear trade-off between material properties and processability.

The Challenge of Fine Powder

Fine PTFE powder has very high intermolecular forces and a unique particle morphology. This results in extremely poor flowability.

It does not flow smoothly from hoppers, can "bridge" or clog equipment, and is difficult to dose accurately. This makes it unsuitable for most automated, high-volume manufacturing processes.

The Advantage of Granules

Agglomerated granules are larger and more spherical. This drastically improves their flow properties.

They can be easily fed through automated machinery, enabling consistent and efficient production of parts through techniques like compression molding. The granules fill molds uniformly, which is essential for creating high-quality, defect-free components.

How This Impacts Your Final Product

The form of the PTFE you choose is dictated entirely by your manufacturing method and desired end-product characteristics.

- If your primary focus is automated compression molding: You must use agglomerated granules. Their excellent flow properties are essential for filling molds consistently and efficiently in a high-volume production environment.

- If your primary focus is creating specialized compounds or pastes: Fine powder may be the required starting material. It allows for more intimate mixing with other fillers or lubricants before any subsequent processing.

- If your primary focus is ram extrusion: Granulated PTFE is the standard choice. The process relies on the material's ability to be fed consistently into the extrusion chamber.

Ultimately, post-polymerization processing is what makes PTFE a versatile and manufacturable fluoropolymer.

Summary Table:

| Processing Step | Key Action | Purpose |

|---|---|---|

| Draining & Drying | Remove water from reaction chamber | Eliminate residual moisture |

| Milling | Grind dry PTFE into fine powder | Create pure, base PTFE form |

| Agglomeration | Tumble powder with solvent to form pellets | Improve flow for manufacturing |

Need high-quality, ready-to-process PTFE components? The post-polymerization steps are crucial for ensuring material consistency and performance. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise in material science and custom fabrication ensures your specifications are met with reliability. Contact us today to discuss how our PTFE solutions can enhance your product performance and manufacturing efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the advantages of using Teflon coating in cooking utensils? Discover Effortless Cooking & Cleaning

- How does PTFE perform under extreme temperatures? Unmatched Stability from -200°C to 260°C

- Who discovered PTFE and when? The Accidental Invention of Teflon

- What chemicals is PTFE resistant to? Discover Its Near-Universal Chemical Inertness

- How is PTFE formed? Unlocking the Secrets of Its Exceptional Properties

- What chemicals can degrade Teflon? A Guide to PTFE's Chemical Limits

- What are the advantages of using Teflon? Achieve Superior Performance in Extreme Conditions

- What is PTFE and why is it used in industrial applications? | The Ultimate Material for Harsh Environments