The defining properties of Polytetrafluoroethylene (PTFE) are its extreme non-reactivity, exceptional thermal stability, and uniquely low coefficient of friction. This synthetic fluoropolymer, widely known by the brand name Teflon, is renowned for its chemical inertness, its ability to withstand a vast range of temperatures, its excellent electrical insulation, and its signature non-stick surface.

PTFE is a material of extremes. Its remarkable resistance to chemicals, heat, and electrical current, combined with the lowest friction of any solid, makes it an elite performer in demanding environments, though these specialized strengths come with notable mechanical limitations.

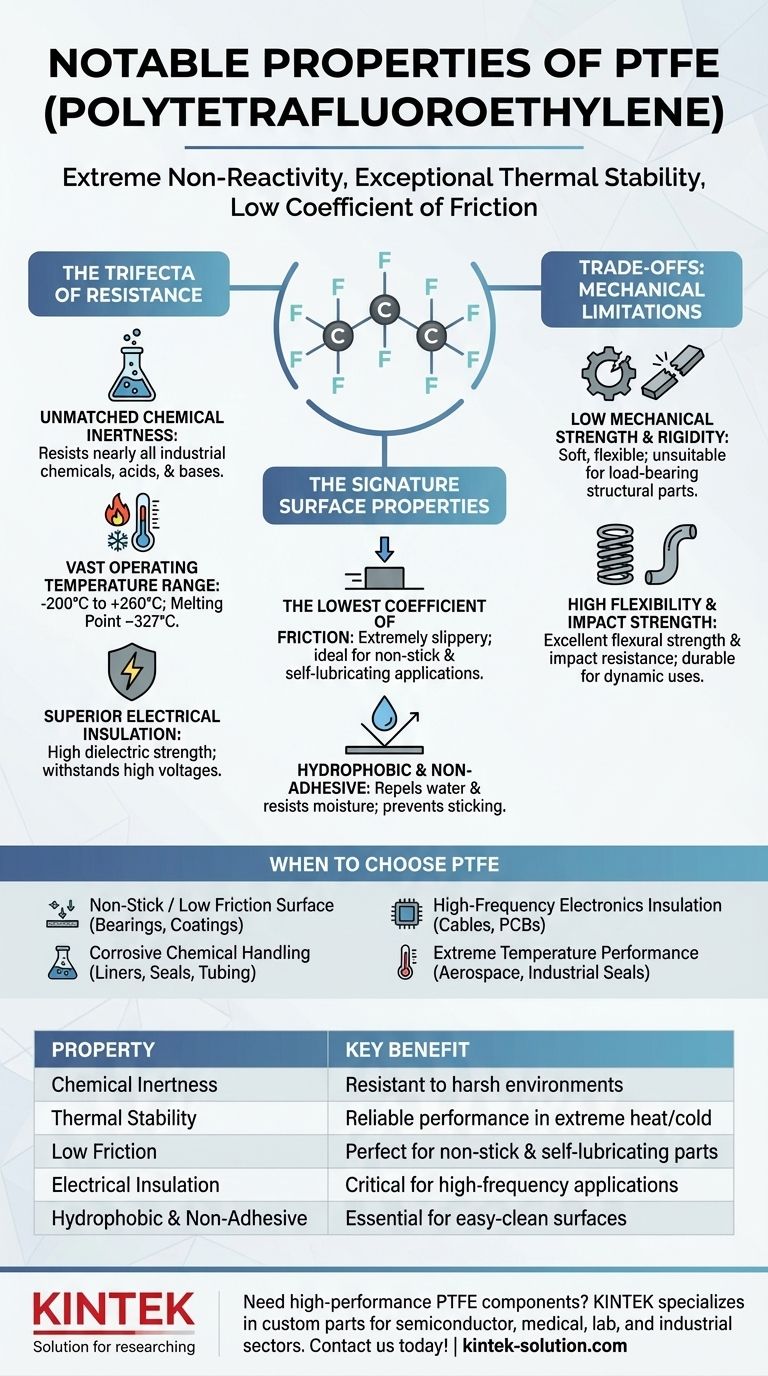

The Trifecta of Resistance: Chemical, Thermal, and Electrical

The core of PTFE's value lies in its profound ability to resist three major sources of material degradation. This resilience stems from the incredibly strong bonds between its carbon and fluorine atoms.

Unmatched Chemical Inertness

PTFE is almost totally chemically inert, meaning it is non-reactive and highly resistant to corrosion. It can withstand exposure to nearly all industrial chemicals, acids, and bases without degrading.

This property makes it an invaluable material for seals, gaskets, and linings in chemical processing, where it handles substances that would destroy most other materials.

A Vast Operating Temperature Range

The material demonstrates remarkable thermal stability, remaining functional across an exceptionally wide temperature spectrum. It is reliably stable for continuous service from -200°C (-328°F) up to +260°C (500°F).

Its high melting point of approximately 327°C (621°F) ensures it does not break down or lose its structural integrity in high-heat applications common in industrial and aerospace settings.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength. This means it can withstand high voltages without allowing an electrical current to flow through it.

This property is particularly valuable in high-frequency electronics, where PTFE is used for insulating cables and as a substrate for printed circuit boards (PCBs).

The Signature Surface Properties

Beyond its resistance, PTFE is most famous for the unique characteristics of its surface, which directly impact how it interacts with other materials.

The Lowest Coefficient of Friction

PTFE boasts one of the lowest coefficients of friction of any known solid. In practical terms, this makes it an extremely slippery material.

This low-friction nature is ideal for applications like non-stick coatings on cookware and low-wear, self-lubricating bearings and gears in machinery.

Hydrophobic and Non-Adhesive

The material is hydrophobic, meaning it repels water and resists moisture absorption. This contributes to its effectiveness as a waterproof barrier.

Combined with its low surface energy, this also makes it non-adhesive. Very few substances will permanently stick to a PTFE surface, a property essential for its use in non-stick cookware and easy-clean industrial coatings.

Understanding the Trade-offs: Mechanical Limitations

While PTFE's specialized properties are unparalleled, it is not a universally perfect material. Its primary limitations are mechanical, which is a critical consideration for engineering applications.

Low Mechanical Strength and Rigidity

Compared to many engineering plastics, PTFE has relatively low tensile strength, stiffness, and hardness. It is a soft, flexible material.

This lack of rigidity means it is generally unsuitable for load-bearing structural components. Its use is often limited to applications that leverage its surface, chemical, and thermal properties rather than its mechanical strength.

High Flexibility and Impact Strength

Despite its low rigidity, PTFE exhibits high flexural strength and impact resistance, especially at low temperatures. It can be bent and flexed repeatedly without breaking.

This makes it a durable elastomer for applications requiring flexibility, such as tubing for corrosive fluids or high-performance seals that must conform to surfaces.

When to Choose PTFE

Selecting PTFE is a strategic choice for applications where its unique strengths directly solve a specific, demanding problem.

- If your primary focus is creating a non-stick or low-friction surface: PTFE is the industry standard for coatings, bearings, and sliding components.

- If your primary focus is containing or transporting corrosive chemicals: Its chemical inertness makes it the ideal choice for linings, seals, and tubing in harsh chemical environments.

- If your primary focus is insulating high-frequency electronics: Its excellent dielectric properties are critical for manufacturing high-performance coaxial cables and circuit boards.

- If your primary focus is performance in extreme temperatures: Its wide operating range makes it a reliable material for seals and components in aerospace and industrial processes.

PTFE is a highly specialized polymer designed to solve problems that most other materials simply cannot.

Summary Table:

| Property | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to nearly all industrial chemicals, acids, and bases. | Ideal for seals and linings in harsh environments. |

| Thermal Stability | Operates from -200°C to +260°C with a high melting point (~327°C). | Reliable performance in extreme heat or cold. |

| Low Friction | One of the lowest coefficients of friction of any solid. | Perfect for non-stick coatings and self-lubricating parts. |

| Electrical Insulation | High dielectric strength, excellent for high-frequency applications. | Critical for insulating cables and PCBs. |

| Hydrophobic & Non-Adhesive | Repels water and prevents substances from sticking. | Essential for easy-clean surfaces and moisture barriers. |

Need high-performance PTFE components that leverage these extreme properties?

KINTEK specializes in the precision manufacturing of custom PTFE parts—including seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures your components meet the demanding requirements of your application.

Contact KINTEB today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability