At its core, Polytetrafluoroethylene (PTFE) is defined by a trifecta of elite properties. It is most famous for having one of the lowest coefficients of friction of any solid, making it exceptionally non-stick and self-lubricating. This is complemented by an extraordinary resistance to virtually all chemicals and a high tolerance for extreme temperatures, allowing it to perform where many other materials fail.

The remarkable characteristics of PTFE all stem from one fundamental source: the immense strength and stability of its carbon-fluorine (C-F) bonds. Understanding this single chemical principle is the key to understanding why PTFE is such a uniquely high-performance polymer.

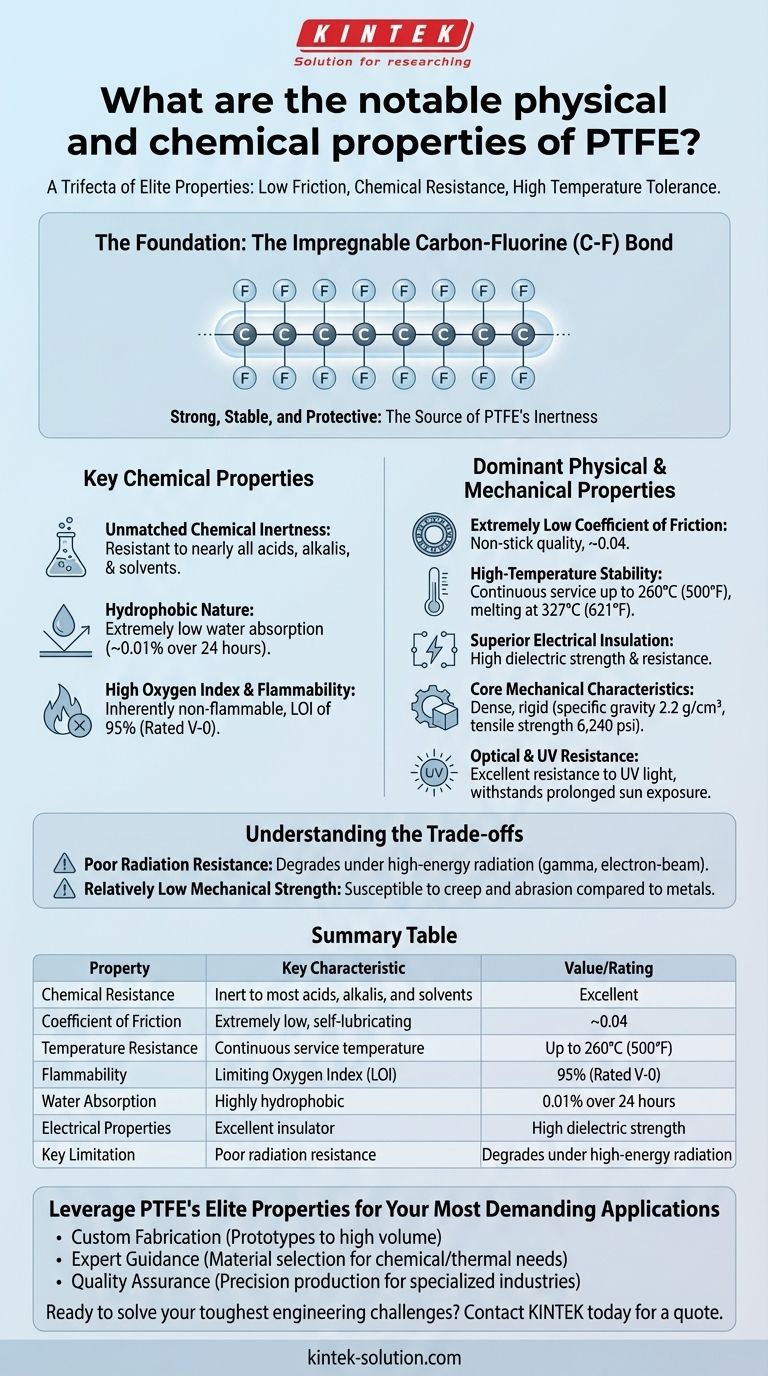

The Foundation: Why PTFE is So Unique

Before listing its properties, it's critical to understand their origin. The entire molecule is built on a chain of carbon atoms, each completely shielded by highly electronegative fluorine atoms.

The Carbon-Fluorine Bond

The bond between carbon and fluorine is exceptionally strong and stable. This powerful bond creates a protective "sheath" around the carbon backbone, making the molecule incredibly difficult for other chemicals to attack or react with. This is the source of PTFE's legendary inertness.

Key Chemical Properties Explained

The chemical stability of PTFE makes it a material of choice for demanding, corrosive, and high-purity applications.

Unmatched Chemical Inertness

PTFE exhibits outstanding resistance to nearly all acids, alkalis, and solvents. This non-reactive nature means it will not degrade or contaminate its environment, which is critical for applications in chemical processing, medical devices, and laboratories.

Hydrophobic Nature (Water Resistance)

Due to its high fluorine content, PTFE is intensely hydrophobic, meaning it repels water. It has an extremely low water absorption rate of just 0.01% over 24 hours, ensuring its properties remain stable even when fully submerged.

High Oxygen Index and Flammability

PTFE is inherently non-flammable. It has a Limiting Oxygen Index (LOI) of 95%, meaning it requires an atmosphere of 95% oxygen to support combustion. For context, Earth's atmosphere is about 21% oxygen. This earns it the highest flammability rating of V-0.

Dominant Physical and Mechanical Properties

PTFE’s physical traits are as impressive as its chemical ones, making it a versatile engineering material.

Extremely Low Coefficient of Friction

The surface energy of PTFE is incredibly low, resulting in a coefficient of friction around 0.04. This is the source of its famous "non-stick" quality, making it an ideal material for coatings on cookware, industrial liners, and self-lubricating bearings.

High-Temperature Stability

PTFE has a very high melting point of 327°C (621°F) and a continuous service temperature of up to 260°C (500°F), the highest among fluoroplastics. It also retains its strength and toughness at cryogenic temperatures, giving it a vast operational range.

Superior Electrical Insulation

As an excellent electrical insulator, PTFE possesses high dielectric strength and electrical resistance. Its properties remain stable across a wide range of frequencies and temperatures, making it a preferred material for high-performance cables, connectors, and circuit boards.

Core Mechanical Characteristics

PTFE is a dense material with a specific gravity of 2.2 g/cm³. It is a rigid polymer with a tensile strength of 6,240 psi and a Rockwell hardness of R58. While not as strong as metal, it possesses high flexural strength, especially at low temperatures.

Optical and UV Resistance

Generally opaque, certain grades of PTFE can be made translucent. A key advantage for outdoor applications is its excellent resistance to ultraviolet (UV) light, which allows it to withstand prolonged sun exposure without degrading.

Understanding the Trade-offs

No material is perfect. While PTFE excels in many areas, its unique structure creates specific limitations that are critical to recognize for proper application.

Poor Radiation Resistance

The primary weakness of PTFE is its poor resistance to high-energy radiation, such as gamma or electron-beam radiation. This type of exposure can break the C-F bonds, causing the polymer to degrade and lose its mechanical properties.

Relatively Low Mechanical Strength

Compared to engineering metals or other high-strength polymers, PTFE has lower tensile strength and is susceptible to creep (cold flow) under load. Its hardness is also relatively low, making it prone to scratching and abrasion if not used in appropriate applications.

Making the Right Choice for Your Application

Selecting PTFE is about leveraging its extreme properties where they are most needed.

- If your primary focus is creating a non-stick, low-friction surface: PTFE is the definitive choice for applications like bearings, seals, and non-stick coatings.

- If your primary focus is resistance to harsh chemicals or solvents: Its unmatched chemical inertness makes it ideal for linings, gaskets, and tubing in the chemical processing industry.

- If your primary focus is high-temperature electrical insulation: Its thermal stability and high dielectric strength make it a top-tier material for wire insulation and electronic components.

- If your primary focus is long-term outdoor or UV stability: Its inherent resistance to UV radiation ensures it will not become brittle or degrade from sun exposure.

PTFE is the definitive material for solving engineering challenges in extreme chemical, thermal, and low-friction environments.

Summary Table:

| Property | Key Characteristic | Value / Rating |

|---|---|---|

| Chemical Resistance | Inert to most acids, alkalis, and solvents | Excellent |

| Coefficient of Friction | Extremely low, self-lubricating | ~0.04 |

| Temperature Resistance | Continuous service temperature | Up to 260°C (500°F) |

| Flammability | Limiting Oxygen Index (LOI) | 95% (Rated V-0) |

| Water Absorption | Highly hydrophobic | 0.01% over 24 hours |

| Electrical Properties | Excellent insulator | High dielectric strength |

| Key Limitation | Poor radiation resistance | Degrades under high-energy radiation |

Leverage PTFE's Elite Properties for Your Most Demanding Applications

Understanding PTFE's unique balance of extreme chemical resistance, non-stick properties, and thermal stability is the first step. Implementing it effectively in your components is the next.

KINTEK specializes in the precision manufacturing of PTFE components—including seals, liners, labware, and custom parts—for the semiconductor, medical, laboratory, and industrial sectors. We help you harness PTFE's full potential while designing around its limitations.

We provide:

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Expert Guidance: Ensuring the right material and design for your specific chemical, thermal, and mechanical requirements.

- Quality Assurance: Precision production that meets the stringent demands of specialized industries.

Ready to solve your toughest engineering challenges with high-performance PTFE? Contact KINTEK today to discuss your project needs and get a quote.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is PTFE commonly used for in construction? Essential Applications for High-Performance Infrastructure

- How does PTFE benefit fabric and carpet protection? Achieve Superior Stain and Soil Resistance

- What fillers are used to enhance PTFE properties? Tailor PTFE for Superior Wear and Strength

- What are the main advantages of using PTFE in manufacturing? Boost Efficiency & Durability

- What is the relationship between PTFE and Teflon? A Guide to the Material vs. the Brand Name

- What is PTFE and why is it significant? Unlock the Power of a High-Performance Polymer

- What are the differences between PTFE and Nylon? Choose the Right Material for Your Application

- What are the properties of bronze-filled PTFE? A High-Performance Composite for Demanding Applications