In short, Polytetrafluoroethylene (PTFE) is a high-performance synthetic fluoropolymer most famous for its extreme non-stick properties, chemical inertness, and ability to withstand a vast range of temperatures. Its unique molecular structure, built on one of the strongest single bonds in organic chemistry, gives it a combination of characteristics unmatched by most other materials.

The source of PTFE's remarkable capabilities is the exceptionally strong bond between its carbon and fluorine atoms. This creates a molecular fortress that is highly resistant to heat, virtually all chemicals, and friction.

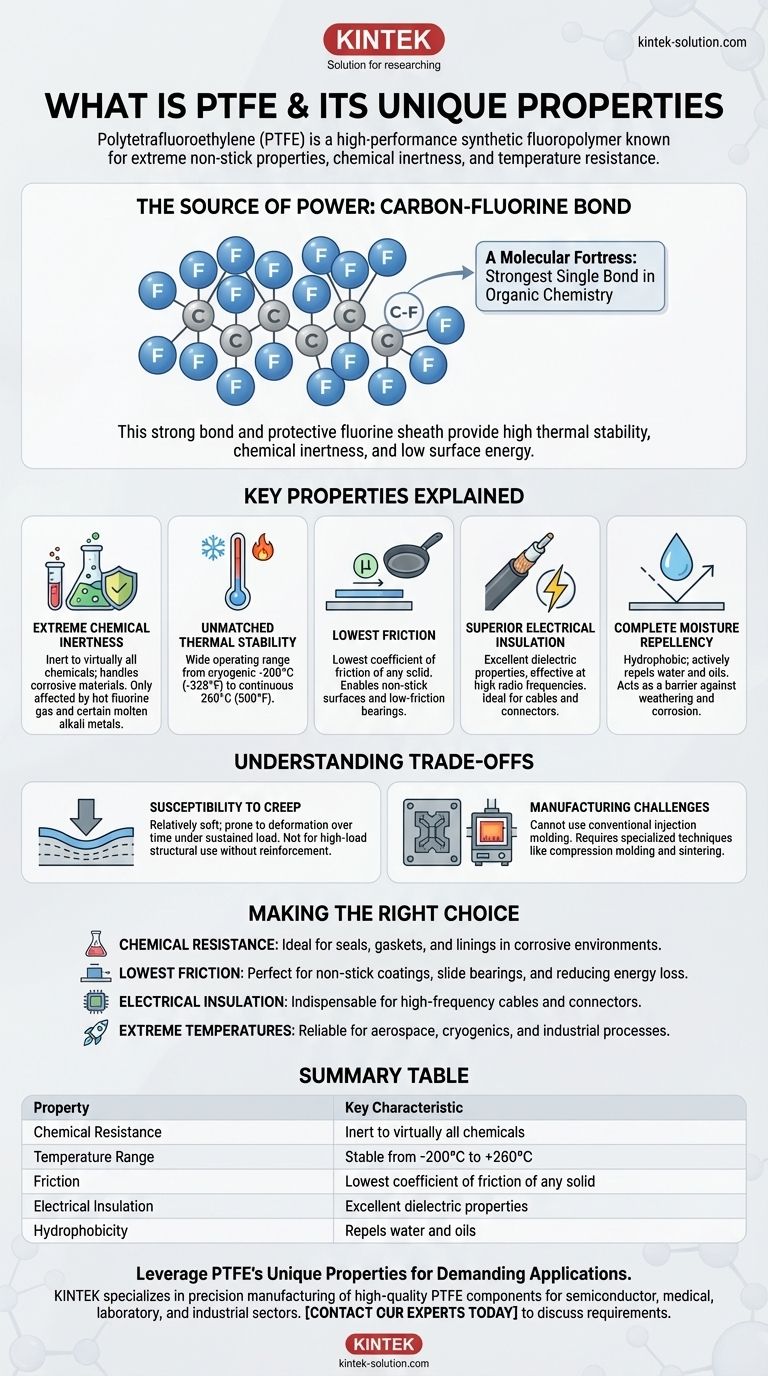

The Source of PTFE's Power: The Carbon-Fluorine Bond

To truly understand PTFE, you must look at its molecular structure. It consists of a long chain of carbon atoms, with each carbon completely surrounded and protected by fluorine atoms.

A Molecular Fortress

The Carbon-Fluorine (C-F) bond is one of the strongest single bonds known in organic chemistry. This immense bond strength is the primary reason for PTFE's high thermal stability and chemical inertness.

Shielding the Carbon Backbone

The fluorine atoms effectively form a protective, non-reactive sheath around the carbon chain. This sheath prevents other chemicals from attacking the backbone and is also responsible for the material's low surface energy, which creates its famous non-stick and water-repellent properties.

Key Properties Explained

The unique molecular structure of PTFE gives rise to a powerful combination of commercial and industrial properties.

Extreme Chemical Inertness

PTFE is almost completely inert, meaning it will not react with the vast majority of chemicals. It is used to handle and store highly corrosive materials and is only known to be affected by a few substances like hot fluorine gas and certain molten alkali metals.

Unmatched Thermal Stability

This material has one of the widest operating temperature ranges of any polymer. It remains functional and stable from cryogenic temperatures of -200°C (-328°F) up to a continuous service temperature of 260°C (500°F).

The Lowest Friction

PTFE possesses the lowest coefficient of friction of any known solid material. This makes it incredibly slick and is the fundamental property behind its use in non-stick cookware and low-friction industrial bearings and coatings.

Superior Electrical Insulation

PTFE has excellent dielectric properties, meaning it is a fantastic electrical insulator. It maintains this high dielectric strength even at high radio frequencies, making it an ideal material for insulators in cables and connectors, especially in high-performance electronics.

Complete Moisture Repellency

The material is hydrophobic, meaning it actively repels water and oils. This moisture resistance also contributes to its excellent performance as a barrier against weathering and corrosion.

Understanding the Trade-offs

No material is perfect. While PTFE's properties are extraordinary, it has practical limitations that are critical to consider.

Susceptibility to Creep

PTFE is a relatively soft material and is prone to "creep," or deformation over time when placed under a sustained load. This makes it unsuitable for certain high-load structural applications without reinforcement.

Manufacturing Challenges

Due to its high melting point and high melt viscosity, PTFE cannot be processed using conventional methods like injection molding or extrusion. It requires specialized techniques like compression molding and sintering, which can increase manufacturing complexity and cost.

Making the Right Choice for Your Goal

PTFE is not a one-size-fits-all solution. Its value is unlocked when its specific strengths are matched to the primary need of an application.

- If your primary focus is chemical resistance: PTFE is the default choice for seals, gaskets, and linings in corrosive environments.

- If your primary focus is the lowest possible friction: It is the ideal material for non-stick coatings, slide bearings, and reducing energy loss in moving parts.

- If your primary focus is high-frequency electrical insulation: Its dielectric properties make it indispensable for high-performance coaxial cables, connectors, and printed circuit boards.

- If your primary focus is performance in extreme temperatures: PTFE's vast operating range makes it a reliable choice for applications in aerospace, cryogenics, and high-temperature industrial processes.

Understanding these core properties allows you to leverage this unique material to solve some of engineering's toughest challenges.

Summary Table:

| Property | Key Characteristic |

|---|---|

| Chemical Resistance | Inert to virtually all chemicals |

| Temperature Range | Stable from -200°C to +260°C |

| Friction | Lowest coefficient of friction of any solid |

| Electrical Insulation | Excellent dielectric properties, even at high frequencies |

| Hydrophobicity | Repels water and oils |

Leverage PTFE's unique properties for your most demanding applications. At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures superior performance and reliability. Contact our experts today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the common filler materials used in RPTFE and their purposes? Enhance PTFE Performance for Demanding Applications

- What types of plating solutions are compatible with PTFE? A Guide to Maximizing Chemical Resistance

- What are the standard sizes available for PTFE sheets and rods? Optimize Your Design & Sourcing

- What are the key characteristics that make Teflon useful in industrial applications? Solve Tough Corrosion, Friction, and Temperature Challenges

- What are the key characteristics of polytetrafluoroethylene (PTFE)? Unlocking High-Performance Material Properties

- What is the chemical composition of Teflon? The Science Behind Its Non-Stick Properties

- What are the main ingredients used in the production of PTFE? Unlocking its High-Performance Properties

- How is Teflon utilized in the automotive industry? Enhance Vehicle Efficiency and Durability