At its core, Polytetrafluoroethylene (PTFE) is a high-performance fluoropolymer defined by an extraordinary combination of properties not found in other materials. It is most famous for its extreme chemical resistance, exceptionally low friction, non-stick surface, and stability across a vast temperature range. These traits make it a unique problem-solver in demanding industrial, medical, and electrical applications.

PTFE's value comes from its ability to perform reliably in environments where other materials would quickly fail due to chemical attack, extreme temperatures, or friction. However, its unique strengths are balanced by distinct mechanical limitations and processing challenges that are critical to understand.

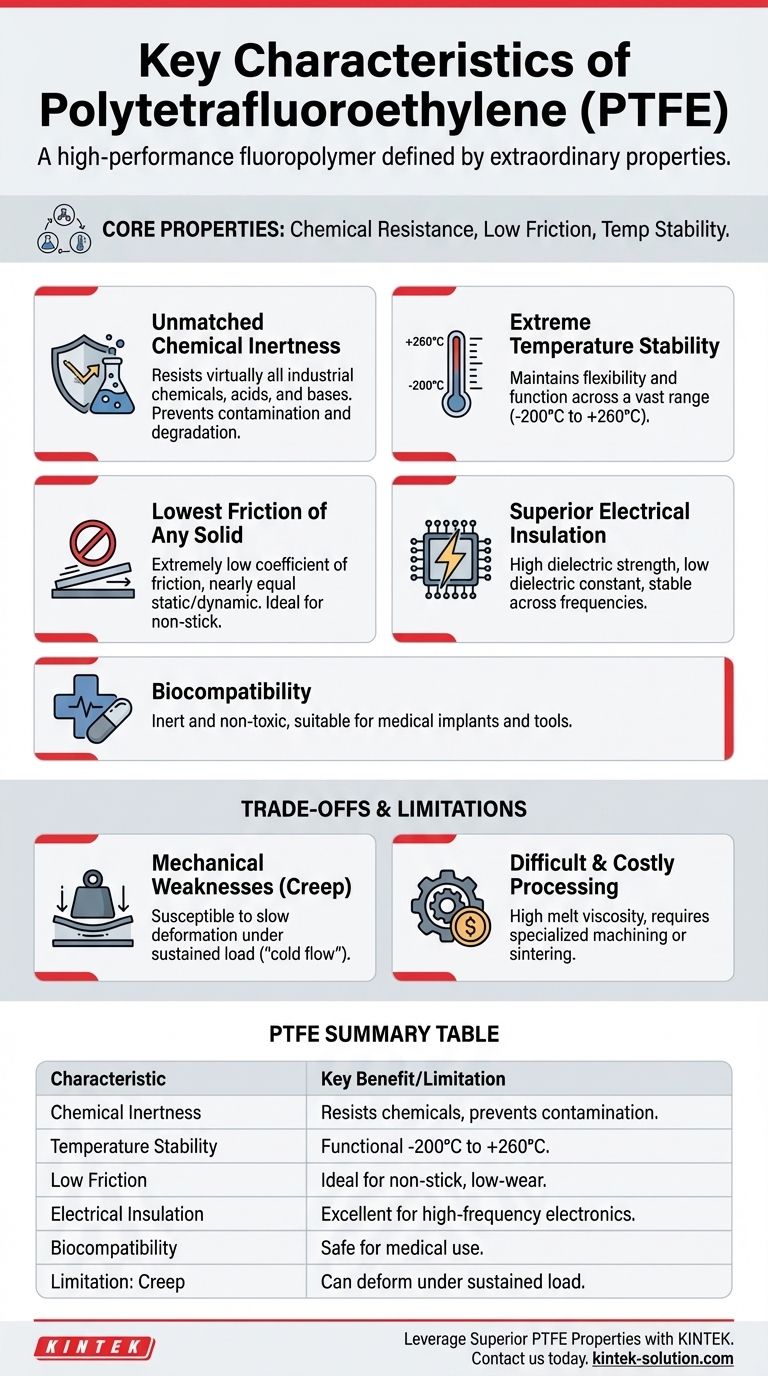

The Core Chemical and Thermal Properties

PTFE's fundamental stability is derived from the strength of its carbon-fluorine bonds, which are among the strongest in organic chemistry. This molecular structure is the source of its most powerful characteristics.

Unmatched Chemical Inertness

Virtually no chemical will react with or degrade PTFE across its entire operational temperature range. This makes it an ideal material for seals, gaskets, and linings that handle highly corrosive or pure substances.

It is resistant to the vast majority of industrial chemicals, solvents, acids, and bases, ensuring material integrity and preventing contamination.

Extreme Temperature Stability

PTFE maintains its properties over an exceptionally wide temperature range, typically from -200°C up to +260°C (-328°F to +500°F).

Unlike many plastics that become brittle in extreme cold or degrade in high heat, PTFE remains flexible, stable, and functional.

Hydrophobic and Weather Resistant

The material is inherently hydrophobic, meaning it repels water and does not absorb moisture. This contributes to its excellent performance in wet environments and its dimensional stability.

Furthermore, PTFE is unaffected by UV radiation and weathering, allowing it to be used in outdoor applications for decades without degradation.

The Unique Surface and Electrical Characteristics

Beyond its chemical backbone, PTFE's physical surface and electrical properties set it apart. These characteristics are not just secondary benefits; they are often the primary reason for its selection.

The Lowest Friction of Any Solid

PTFE has an extremely low coefficient of friction, one of the lowest of any known solid material. Its static and dynamic friction coefficients are nearly equal, preventing stick-slip motion.

This is the property that makes it the ideal non-stick coating for cookware (as Teflon®) and a superior material for low-friction bearings and sliding surfaces.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with a high dielectric strength and low dielectric constant. Crucially, these properties remain stable across a wide range of frequencies and temperatures.

This makes it a top-tier choice for high-frequency applications like coaxial cables, connectors, and printed circuit boards where signal integrity is paramount.

Biocompatibility

Because it is so inert and non-toxic, PTFE is highly biocompatible. The human body does not react to it, making it suitable for a variety of medical applications, including implants, surgical tools, and catheters.

Understanding the Trade-offs and Limitations

No material is perfect, and a true technical assessment requires acknowledging a material's weaknesses. PTFE's primary limitations are mechanical and economic.

Mechanical Weaknesses: Creep and Cold Flow

While tough and flexible, PTFE is a relatively soft material. Under sustained compressive load, it is subject to "creep" or "cold flow"—a slow, continuous deformation.

This means standard PTFE is generally not suitable for applications requiring high structural strength or tight, maintained tolerances under a constant load.

Difficult and Costly Processing

PTFE has a very high melt viscosity, which means it cannot be processed using conventional melt-extrusion or injection molding techniques common for other plastics.

Instead, it is typically machined from stock shapes (rods, sheets) or formed through a sintering process. This makes manufacturing PTFE components more complex and significantly more expensive.

Making the Right Choice for Your Application

Selecting PTFE is a decision based on whether its elite performance in specific areas outweighs its mechanical and cost limitations for your goal.

- If your primary focus is low friction and non-stick surfaces: PTFE is an unparalleled choice for applications like self-lubricating bearings, cable linings, and non-stick coatings.

- If your primary focus is chemical and thermal resistance: It is the definitive material for seals, gaskets, labware, and components exposed to corrosive chemicals or extreme temperatures.

- If your primary focus is structural integrity under load: You must account for PTFE's tendency to creep or consider using filled grades of PTFE that incorporate materials like glass or carbon to improve mechanical strength.

Ultimately, leveraging PTFE successfully depends on designing your application around its extraordinary strengths while respecting its inherent limitations.

Summary Table:

| Characteristic | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and bases. | Prevents contamination and degradation. |

| Temperature Stability | Functional from -200°C to +260°C (-328°F to +500°F). | Reliable performance in extreme environments. |

| Low Friction | One of the lowest coefficients of friction of any solid. | Ideal for non-stick and low-wear applications. |

| Electrical Insulation | High dielectric strength, stable across frequencies and temperatures. | Excellent for high-frequency electronics. |

| Biocompatibility | Non-toxic and inert, suitable for medical use. | Safe for implants and surgical tools. |

| Limitation: Creep | Can deform under sustained load (cold flow). | Not ideal for high structural load applications. |

Leverage PTFE's Superior Properties for Your Critical Components

Understanding PTFE's characteristics is the first step. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—that are engineered to maximize these benefits while mitigating limitations like creep through expert design and material selection.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication from prototypes to high-volume orders. Our focus on precision ensures your components perform reliably in the most demanding environments.

Ready to solve your application challenges with high-performance PTFE? Contact KINTEK today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the benefits of PTFE's chemical resistance? Achieve Unmatched Reliability in Corrosive Environments

- What are the basic properties of PTFE as a thermoplastic polymer? A Guide to Its High-Performance Traits

- What are the benefits of stainless steel-filled PTFE? Enhance Strength and Temperature Resistance

- What forms is PTFE available in besides sheets and rods? Discover the Full Range of PTFE Options

- How was Teflon discovered and what was its initial use? From Lab Accident to Wartime Innovation

- What substances can affect the carbon-fluorine bonds of PTFE? The Rare Chemicals That Challenge PTFE

- How does Teflon differ from other plastics? Discover Its Unique Advantages for Extreme Environments

- What is PTFE's resistance to fluorine under different conditions? Avoid Costly Failures with Temperature-Specific Data