At its core, Teflon's industrial value stems from a unique combination of three defining characteristics. These are its extreme chemical inertness, its remarkably low coefficient of friction, and its stability across an exceptionally wide range of temperatures. This trifecta makes Polytetrafluoroethylene (PTFE), the polymer behind the Teflon brand, a premier problem-solving material in demanding operational environments.

Teflon is not just a single-purpose material; it's an engineering solution for hostile environments. Its true value lies in its ability to simultaneously resist chemical attack, extreme temperatures, and mechanical friction, solving reliability and maintenance challenges where other materials fail.

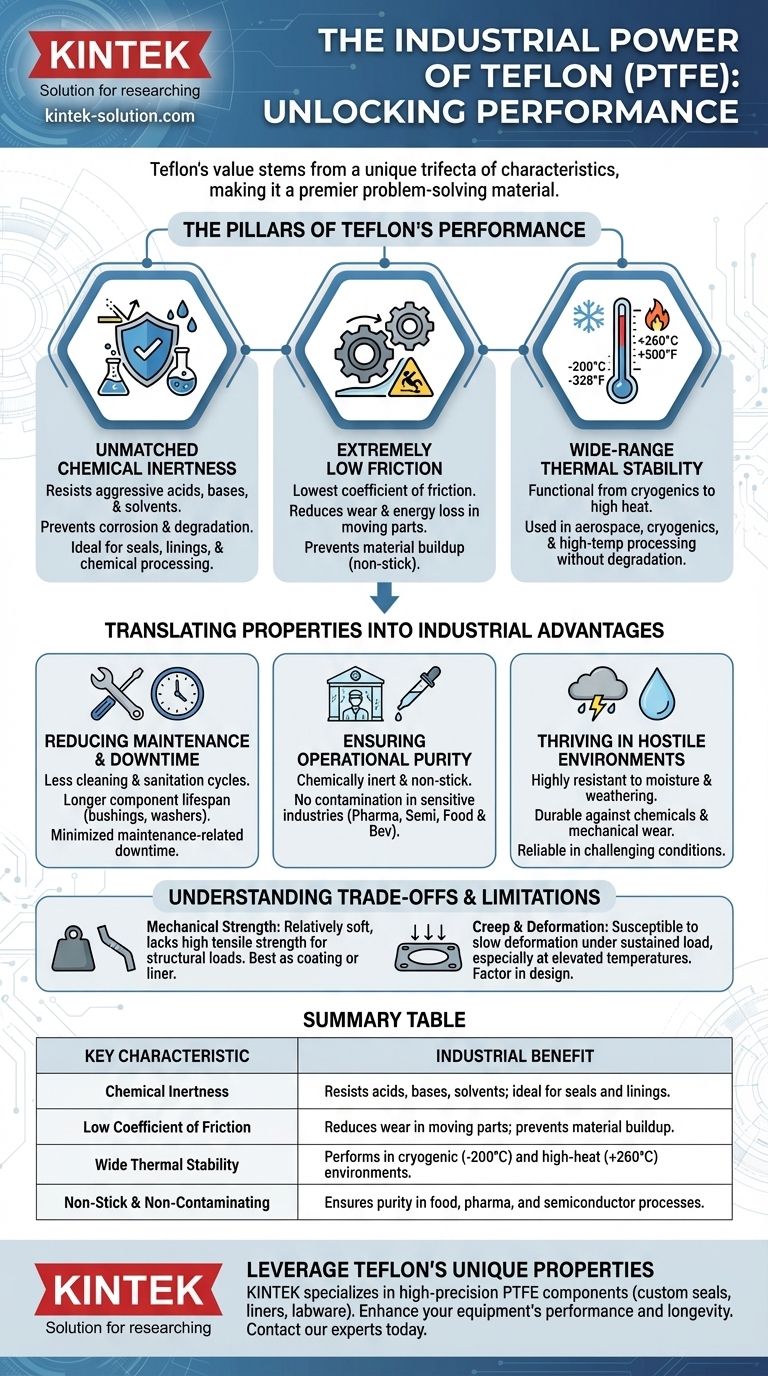

The Pillars of Teflon's Performance

To understand why Teflon is so ubiquitous in industrial settings, we must examine its foundational properties. These characteristics work in concert to deliver unparalleled reliability.

Unmatched Chemical Inertness

Teflon is practically inert, meaning it does not react with the vast majority of industrial chemicals. It exhibits exceptional resistance to aggressive acids, bases, and solvents.

This property makes it an ideal material for seals, linings, and components used in chemical processing, preventing corrosion and material degradation that would destroy lesser materials.

Only a few substances, such as molten alkali metals, can compromise its chemical structure.

Extremely Low Friction

Teflon possesses one of the lowest coefficients of friction of any known solid. This gives it a "slippery" or non-stick quality that is vital for two key industrial functions.

First, it dramatically reduces wear and energy loss in moving parts like bushings and bearings. Second, its non-stick surface prevents viscous or sticky materials from building up, which is critical in industries like food processing.

Wide-Range Thermal Stability

The material demonstrates remarkable stability across a vast temperature spectrum. It remains functional and does not degrade in continuous service from cryogenic lows of -200°C (-328°F) up to highs of +260°C (+500°F).

This allows it to be used in applications ranging from aerospace and cryogenics to high-temperature industrial processing without losing its core properties.

Translating Properties into Industrial Advantages

These core characteristics directly translate into tangible benefits that solve common engineering and operational problems.

Reducing Maintenance and Downtime

By preventing material buildup on machinery surfaces, Teflon coatings significantly reduce the need for cleaning and sanitation cycles, boosting production efficiency.

In mechanical systems, its low-friction nature means components like washers and bushings last longer, extending equipment lifespan and minimizing maintenance-related downtime.

Ensuring Operational Purity

Because Teflon is chemically inert and non-stick, it does not contaminate the materials it comes into contact with.

This is a non-negotiable requirement in sensitive industries such as pharmaceuticals, semiconductor manufacturing, and food and beverage processing, where process purity is paramount.

Thriving in Hostile Environments

Teflon is highly resistant to moisture absorption, making it an excellent choice for wet or humid environments where corrosion is a concern.

When combined with its resistance to weathering, chemicals, and mechanical wear, Teflon proves itself to be an incredibly durable and reliable material for the most challenging conditions.

Understanding the Trade-offs and Limitations

No material is perfect. While Teflon's properties are exceptional, its limitations must be considered for proper application.

Mechanical Strength

Teflon is a relatively soft polymer. While it has good impact strength, it lacks the high tensile strength and rigidity of metals or other engineering plastics.

It is not suitable for high-load structural applications. Instead, it excels as a coating, a liner, or in components specifically designed to leverage its low friction and chemical resistance.

Creep and Deformation

Like many polymers, Teflon can be susceptible to "creep"—a slow deformation under a sustained load, particularly at elevated temperatures.

This must be factored into the design of components like seals and gaskets to ensure they maintain their integrity and sealing force over the product's entire lifecycle.

Making the Right Choice for Your Goal

To apply Teflon effectively, align its specific strengths with your primary engineering challenge.

- If your primary focus is reducing mechanical wear: Use Teflon for components like bushings, wear pads, and slide plates to dramatically lower friction between moving parts.

- If your primary focus is corrosion resistance: Specify Teflon linings or components for systems handling aggressive acids, bases, or solvents.

- If your primary focus is process purity and efficiency: Apply Teflon coatings to surfaces in food, pharmaceutical, or chemical processing to prevent buildup and ensure easy cleaning.

- If your primary focus is performance in extreme temperatures: Select Teflon for seals and components in both high-heat and cryogenic systems where other polymers would degrade.

By understanding these core characteristics, you can strategically leverage Teflon to enhance equipment longevity, reduce maintenance, and ensure operational reliability in your most demanding applications.

Summary Table:

| Key Characteristic | Industrial Benefit |

|---|---|

| Chemical Inertness | Resists acids, bases, solvents; ideal for seals and linings. |

| Low Coefficient of Friction | Reduces wear in moving parts; prevents material buildup. |

| Wide Thermal Stability (-200°C to +260°C) | Performs in cryogenic and high-heat environments. |

| Non-Stick & Non-Contaminating | Ensures purity in food, pharma, and semiconductor processes. |

Leverage Teflon's unique properties to solve your specific industrial challenge.

At KINTEK, we specialize in manufacturing high-precision PTFE (Teflon) components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need to reduce equipment wear, resist corrosive chemicals, ensure process purity, or operate in extreme temperatures, our custom fabrication from prototypes to high-volume orders delivers the reliability your application demands.

Contact our experts today to discuss how our PTFE solutions can enhance your equipment's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability