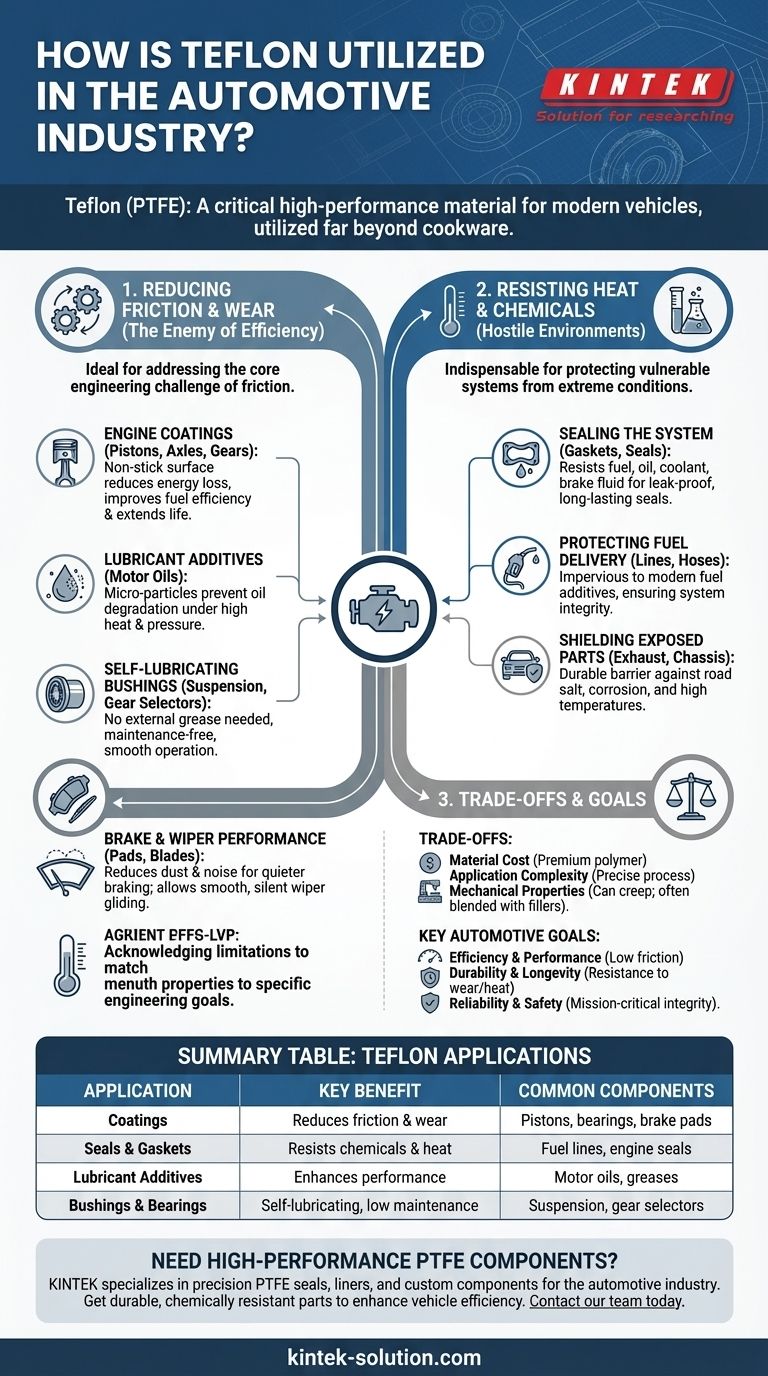

Teflon, or Polytetrafluoroethylene (PTFE), is a critical material in modern vehicles, utilized far beyond its common association with cookware. In the automotive industry, it serves as a high-performance coating to reduce friction on engine and brake parts, as a durable material for fuel lines and seals that resist harsh chemicals and heat, and as a performance-enhancing additive in lubricants. These applications are essential for improving vehicle efficiency, reliability, and lifespan.

The core value of Teflon in automotive engineering is its unique ability to solve three fundamental challenges simultaneously: reducing friction, resisting extreme heat and chemicals, and preventing wear. This combination allows engineers to build more durable, efficient, and reliable vehicles by protecting critical components from the intense stresses of operation.

The Core Problem: Overcoming Friction and Wear

Friction is the enemy of efficiency and longevity. It generates heat, wastes energy, and wears down components over time. Teflon's extremely low coefficient of friction makes it an ideal solution for addressing this core engineering challenge.

Coating for Engine Components

PTFE is applied as a coating to parts like pistons, axles, ball bearings, and gears. This non-stick, low-friction surface reduces the energy lost to friction within the engine.

The direct results are improved fuel efficiency, reduced operating temperatures, and a significant extension of the engine's service life.

Enhancing Lubricants and Oils

Teflon is used as a micro-particle additive in motor oils and other lubricants. It acts as an internal lubricant, circulating with the oil to coat metal surfaces.

This application is particularly effective at preventing oil degradation and maintaining performance under the high-temperature, high-pressure conditions found in modern engines.

Self-Lubricating Bushings and Bearings

In systems like vehicle suspensions, gear selectors, and brake assemblies, Teflon bushes are frequently used.

Because the material is inherently slick, these components are self-lubricating. This eliminates the need for external grease or oil, reducing maintenance requirements and providing a consistent, smooth operation over the vehicle's lifetime.

Improving Brake and Wiper Performance

Coatings are also applied to brake pads and related hardware. This helps to reduce brake dust and noise (vibration), leading to a quieter and cleaner braking system.

Similarly, a thin layer of Teflon on windshield wiper blades allows them to glide smoothly and silently across the glass, improving both performance and durability.

The Second Challenge: Resisting Heat and Chemicals

A vehicle's engine bay and underbody are hostile environments, exposed to corrosive fluids, road salt, and extreme temperature swings. Teflon's chemical inertness and high-temperature stability make it indispensable for protecting vulnerable systems.

Sealing the System

Gaskets and seals made from Teflon are used throughout the engine and transmission. Its ability to resist degradation from fuel, oil, coolant, and brake fluid ensures a long-lasting, leak-proof seal.

This prevents fluid loss and protects sensitive electronics and mechanical parts from contamination.

Protecting Fuel Delivery

Modern fuels contain additives that can degrade conventional rubber and plastic. Fuel lines and hoses made from or lined with Teflon are impervious to these chemicals.

This ensures the integrity of the fuel delivery system, preventing dangerous leaks and maintaining consistent engine performance.

Shielding Exposed Parts

Teflon-based coatings are applied to components like exhaust systems, chassis parts, and underbodies.

This provides a durable barrier against corrosion from road salt and other environmental chemicals, as well as protecting against high temperatures radiating from the engine and exhaust.

Understanding the Trade-offs

While highly effective, Teflon is not a universal solution. Acknowledging its limitations is key to understanding its specific role in automotive design.

Material Cost

PTFE is a premium polymer and is generally more expensive than traditional materials like rubber or standard plastics. Its use is typically justified in applications where its unique performance characteristics are critical for longevity and reliability.

Application Complexity

Applying Teflon coatings is a precise industrial process that requires specialized equipment and expertise to ensure proper adhesion and thickness. It is not a simple treatment.

Mechanical Properties

In its pure form, PTFE can be relatively soft and may deform under sustained, heavy loads—a property known as "creep." For structural parts like bushings or high-load seals, it is often blended with fillers like glass, carbon, or bronze to increase its strength and rigidity.

How Teflon Solves Key Automotive Goals

Choosing a material is about matching its properties to a specific engineering goal. Teflon's versatility allows it to address several primary objectives in vehicle design.

- If your primary focus is Efficiency and Performance: Teflon's low-friction properties in engine coatings, bearings, and lubricants directly reduce parasitic energy loss, improving fuel economy and power output.

- If your primary focus is Durability and Longevity: Its exceptional resistance to wear, high heat, and chemical corrosion in seals, hoses, and protective coatings extends the operational life of the most critical vehicle components.

- If your primary focus is Reliability and Safety: Using Teflon for mission-critical components like fuel lines and brake system seals ensures they maintain their integrity under the most demanding conditions, preventing catastrophic failures.

Ultimately, Teflon is a versatile engineering polymer that works behind the scenes to make modern vehicles more resilient, efficient, and dependable.

Summary Table:

| Application | Key Benefit | Common Components |

|---|---|---|

| Coatings | Reduces friction & wear | Pistons, bearings, brake pads |

| Seals & Gaskets | Resists chemicals & heat | Fuel lines, engine seals |

| Lubricant Additives | Enhances performance | Motor oils, greases |

| Bushings & Bearings | Self-lubricating, low maintenance | Suspension, gear selectors |

Need high-performance PTFE components for your automotive applications? KINTEK specializes in manufacturing precision PTFE seals, liners, and custom components that meet the demanding requirements of the automotive industry. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get durable, chemically resistant parts that enhance vehicle efficiency and reliability. Contact our team today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability