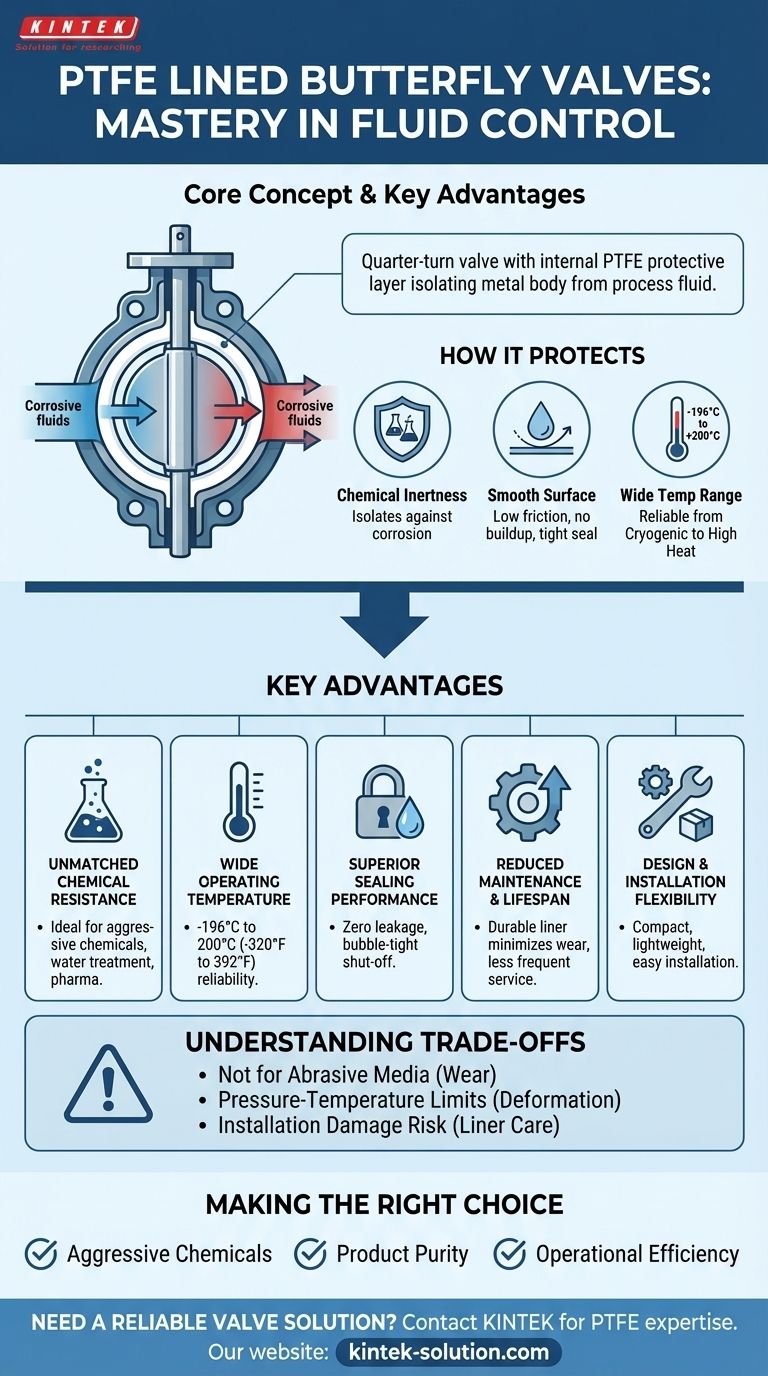

At its core, a PTFE lined butterfly valve is a quarter-turn valve that uses a protective internal layer of Polytetrafluorofluoroethylene (PTFE) to isolate the valve's metal body from the process fluid. Its primary advantages stem directly from the properties of this PTFE lining: exceptional chemical resistance, a wide operating temperature range, and excellent non-stick properties that ensure a tight seal and reduce maintenance.

The central purpose of a PTFE lined butterfly valve is to provide a cost-effective and highly reliable solution for controlling corrosive or high-purity fluids. It achieves this by using a chemically inert liner to protect a standard metal valve body, combining the structural strength of metal with the superior resistance of PTFE.

How the PTFE Lining Provides Protection

### The Core Components

A PTFE lined butterfly valve consists of a standard valve body, typically made from robust materials like carbon steel or stainless steel, and a central disc. The key feature is the molded PTFE liner that covers all wetted surfaces inside the valve body, creating a seamless protective barrier.

### The Protective Barrier Principle

This PTFE liner is the valve's critical element. It completely isolates the process fluid—whether it's a harsh acid, alkali, or solvent—from the metallic valve body and stem. This prevents chemical corrosion that would quickly degrade an unlined metal valve.

### Smooth Flow and Tight Sealing

PTFE is known for its extremely low coefficient of friction, creating a smooth, non-stick surface. This not only allows fluids to flow with minimal resistance but also prevents media from building up on the valve's internal parts, reducing wear and ensuring a reliable, tight shut-off.

Key Advantages in Detail

### Unmatched Chemical Resistance

The primary benefit is PTFE's inertness to nearly all industrial chemicals. This makes the valve an ideal choice for aggressive applications found in chemical processing, water treatment, and pharmaceutical manufacturing where media compatibility is critical.

### Wide Operating Temperature Range

These valves perform reliably across a broad spectrum of temperatures. They maintain their integrity and sealing capability in conditions ranging from cryogenic lows of -196°C up to high temperatures of 200°C (-320°F to 392°F).

### Superior Sealing Performance

The combination of the liner's smooth surface and the valve's design mechanics allows for excellent sealing capabilities. In many applications, these valves can achieve a "zero leakage" or bubble-tight shut-off, which is essential for handling toxic or valuable media.

### Reduced Maintenance and Extended Lifespan

Because the process fluid only touches the durable PTFE liner, wear and tear on the valve's core components are significantly minimized. The non-stick surface resists scaling and buildup, leading to less frequent maintenance and a longer operational life.

### Design and Installation Flexibility

Butterfly valves are inherently compact and lightweight compared to other valve types like gate or globe valves. This makes them easier to install, especially in tight spaces, and their simple design allows for installation in various orientations within a piping system.

Understanding the Trade-offs

### Not Ideal for Abrasive Media

While excellent for corrosive liquids and gases, PTFE is a relatively soft material. It is generally not recommended for services containing abrasive particles or heavy slurries, as these can physically wear down or erode the liner over time, compromising its protective barrier.

### Pressure and Temperature Limitations

Although the temperature range is wide, PTFE is subject to specific pressure-temperature limits. At the higher end of its temperature range, the maximum allowable pressure decreases. Exceeding these limits can cause the liner to deform or "creep," potentially leading to seal failure.

### Susceptibility to Installation Damage

The integrity of the liner is paramount. Care must be taken during installation and maintenance to avoid scratching or gouging the PTFE surface. Any damage to the liner can create a weak point for chemical attack on the underlying valve body.

Making the Right Choice for Your Application

Ultimately, selecting this valve depends on the specific demands of your process.

- If your primary focus is handling aggressive chemicals: This valve offers one of the most reliable and cost-effective solutions for controlling corrosive media without resorting to expensive, full-alloy valve bodies.

- If your primary focus is product purity: The inert, non-stick nature of PTFE ensures that the valve will not contaminate sensitive media, making it ideal for pharmaceutical, food, and beverage applications.

- If your primary focus is operational efficiency: The valve's simple quarter-turn operation, low maintenance needs, and reliable sealing contribute to efficient and uninterrupted production processes.

This valve masterfully combines mechanical strength with chemical resilience, making it a definitive solution for the toughest fluid handling challenges.

Summary Table:

| Feature | Benefit |

|---|---|

| PTFE Lining | Isolates process fluid from metal body, providing exceptional chemical resistance. |

| Wide Temperature Range | Operates reliably from -196°C to 200°C (-320°F to 392°F). |

| Non-Stick Surface | Ensures a tight seal, prevents media buildup, and reduces maintenance. |

| Compact & Lightweight | Easy to install in tight spaces with flexible orientation options. |

Need a reliable valve for aggressive chemicals or high-purity processes?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-fabricated seals, liners, and labware. Our precision production ensures your valves and systems deliver maximum chemical resistance and operational efficiency.

Whether you require a standard solution or a custom prototype for the semiconductor, medical, laboratory, or industrial sectors, we are your trusted partner from design to high-volume production.

Contact KINTEK today to discuss your specific application and discover how our PTFE expertise can solve your toughest fluid control challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the difference between PTFE valves and PFA valves? Choose the Right Fluoropolymer for Your System

- What advantage does the low friction property of PTFE oil seals provide? Extend Equipment Life & Save Energy

- How are custom PTFE parts used in the automotive sector? Enhance Vehicle Performance & Durability

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What are the benefits of using Teflon bellow mechanical seals in high-temperature applications? Superior Sealing for Harsh Chemicals

- What are the two main types of lip seals? PTFE Metal-Cased vs. All-Polymer Seals Explained

- What are the key properties and applications of PTFE packing? Discover Its Versatility in Harsh Environments

- What role do PTFE guide strips play in the aerospace industry? Ensure Safety and Reliability in Critical Systems