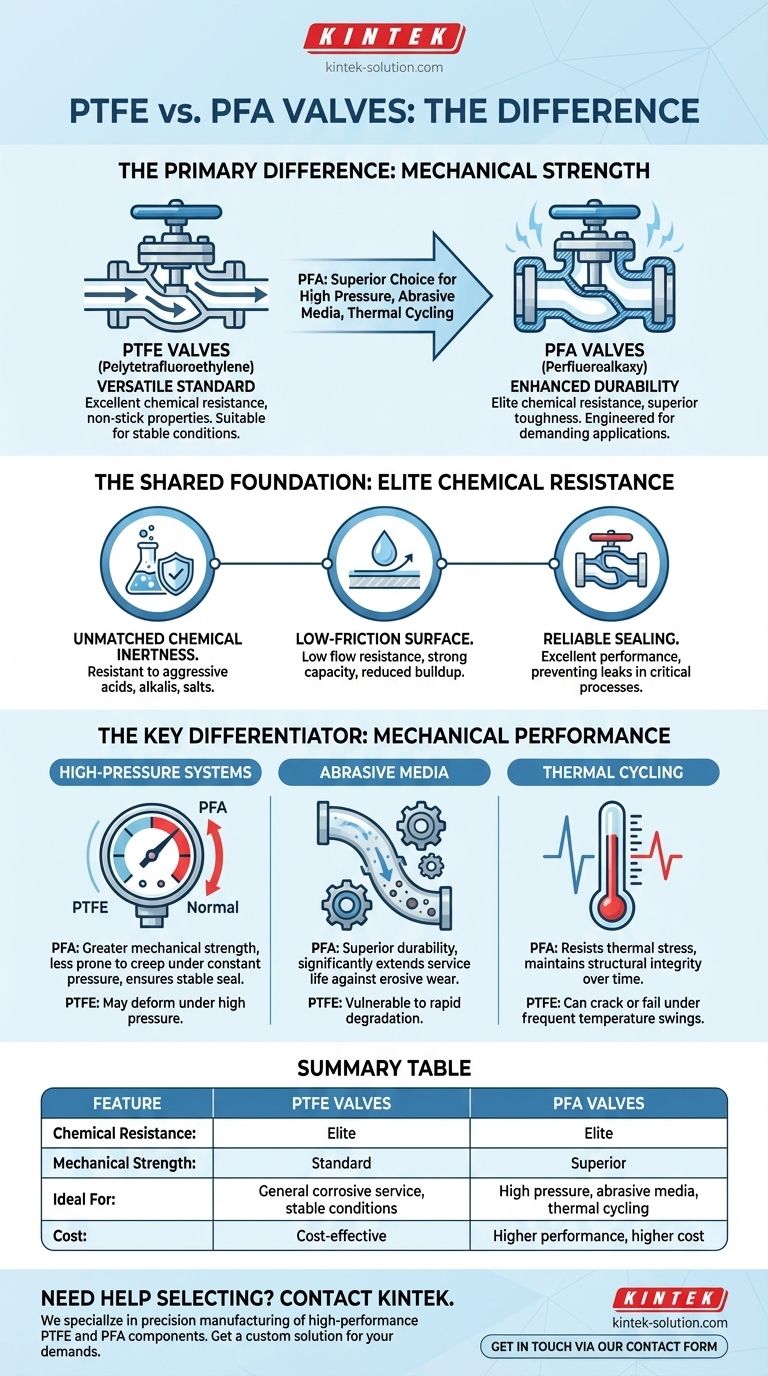

The primary difference between PTFE and PFA valves is mechanical strength. While both materials offer elite chemical resistance and non-stick properties, PFA (Perfluoroalkoxy) is engineered for greater durability. This makes PFA the superior choice for more demanding applications involving high pressure, abrasive media, or significant temperature fluctuations.

While both PTFE and PFA provide exceptional chemical inertness, the decision comes down to your system's operational stress. Choose standard PTFE for general use, but select the mechanically superior PFA for high-pressure, abrasive, or thermally dynamic environments.

The Shared Foundation: Elite Chemical Resistance

Before examining the differences, it's important to understand that both PTFE and PFA are fluoropolymers. They belong to the same chemical family and share a core set of elite characteristics, making them ideal for lining valves in corrosive service.

Unmatched Chemical Inertness

Both PTFE and PFA are almost universally resistant to chemical attack. They can safely handle a vast range of weak or strong corrosive media, including aggressive acids, alkalis, and salts.

Low-Friction Surface

The materials are famous for their non-stick surfaces. In a valve, this results in low flow resistance, strong flow capacity, and reduced potential for media buildup.

Reliable Sealing

Valves lined with these materials often use a soft seal seat design. This ensures excellent sealing performance, preventing leaks in critical processes.

The Key Differentiator: Mechanical Performance

The crucial divergence between these two materials is how they respond to physical stress. PFA was developed to retain PTFE's chemical properties while overcoming some of its mechanical limitations.

PTFE: The Versatile Standard

PTFE (Polytetrafluoroethylene) is the original and most widely known fluoropolymer. It is an excellent and versatile choice for a majority of industrial chemical applications where conditions are relatively stable.

PFA: Enhanced Strength and Durability

PFA offers significantly better mechanical properties than PTFE. This enhanced toughness makes it more resistant to deformation, cracking, and wear under demanding conditions.

Impact on High-Pressure Systems

PFA's greater mechanical strength makes it a more reliable choice for high-pressure systems. It is less prone to creep or deform under constant pressure, ensuring a more stable and long-lasting seal.

Resistance to Abrasive Media

For fluids that contain suspended solids or are otherwise abrasive, PFA is the clear winner. Its superior durability provides much greater resistance to the erosive wear that can quickly degrade a standard PTFE lining.

Superiority in Thermal Cycling

Processes that involve frequent and significant temperature swings put mechanical stress on valve components. PFA handles this thermal cycling much better than PTFE, maintaining its structural integrity and sealing capability over time.

Understanding the Trade-offs

Choosing between PTFE and PFA is not about which is "better" in a vacuum, but which is appropriate for the specific application. The primary trade-off is performance versus cost.

Performance vs. Cost

PFA's enhanced mechanical properties come at a higher price point. For applications without high pressure, abrasion, or thermal cycling, the added cost of PFA may not be justified. PTFE provides exceptional value for standard corrosive services.

Application Suitability

Misapplying the material can lead to premature failure. Using a PTFE valve in a high-pressure or abrasive service is a common mistake that can compromise system safety and lead to costly downtime. Conversely, over-specifying PFA for a simple application is an unnecessary expense.

Making the Right Choice for Your Application

To select the correct valve material, analyze the specific demands of your system.

- If your primary focus is general chemical processing with stable temperatures and pressures: PTFE is the reliable and cost-effective industry standard.

- If your system involves high-pressure media or frequent pressure spikes: PFA's superior mechanical strength provides a crucial margin of safety and reliability.

- If you are handling abrasive slurries or fluids with particulates: PFA's enhanced durability will significantly extend the valve's service life.

- If your process includes significant or rapid temperature cycling: PFA's resistance to thermal stress makes it the more robust and dependable choice.

By aligning the material's mechanical properties with your specific operational demands, you ensure both system integrity and long-term performance.

Summary Table:

| Feature | PTFE Valves | PFA Valves |

|---|---|---|

| Chemical Resistance | Elite | Elite |

| Mechanical Strength | Standard | Superior |

| Ideal For | General corrosive service, stable conditions | High pressure, abrasive media, thermal cycling |

| Cost | Cost-effective | Higher performance, higher cost |

Need help selecting the right valve material for your demanding application?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE and PFA components, including custom valves, seals, and liners. Whether your application is in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures you get a solution that delivers optimal chemical resistance and mechanical durability.

We offer custom fabrication from prototypes to high-volume orders, ensuring your components are perfectly tailored to handle specific pressures, temperatures, and abrasive media.

Contact us today to discuss your requirements and let our experts help you achieve maximum system integrity and longevity. Get in touch via our contact form

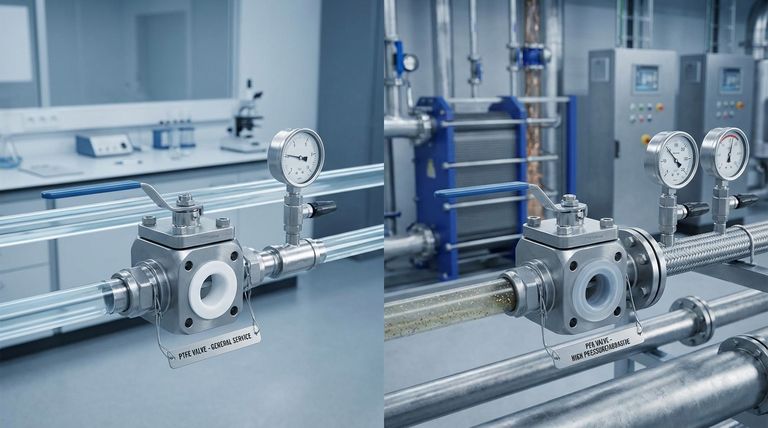

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability