In the aerospace industry, PTFE guide strips function as critical, low-friction bearing elements within hydraulic and pneumatic systems. They are specifically designed to prevent metal-to-metal contact between moving parts, such as in landing gear and flight control actuators. This core function protects components from wear, reduces friction, absorbs side loads, and ensures the smooth, reliable operation of an aircraft's most vital systems.

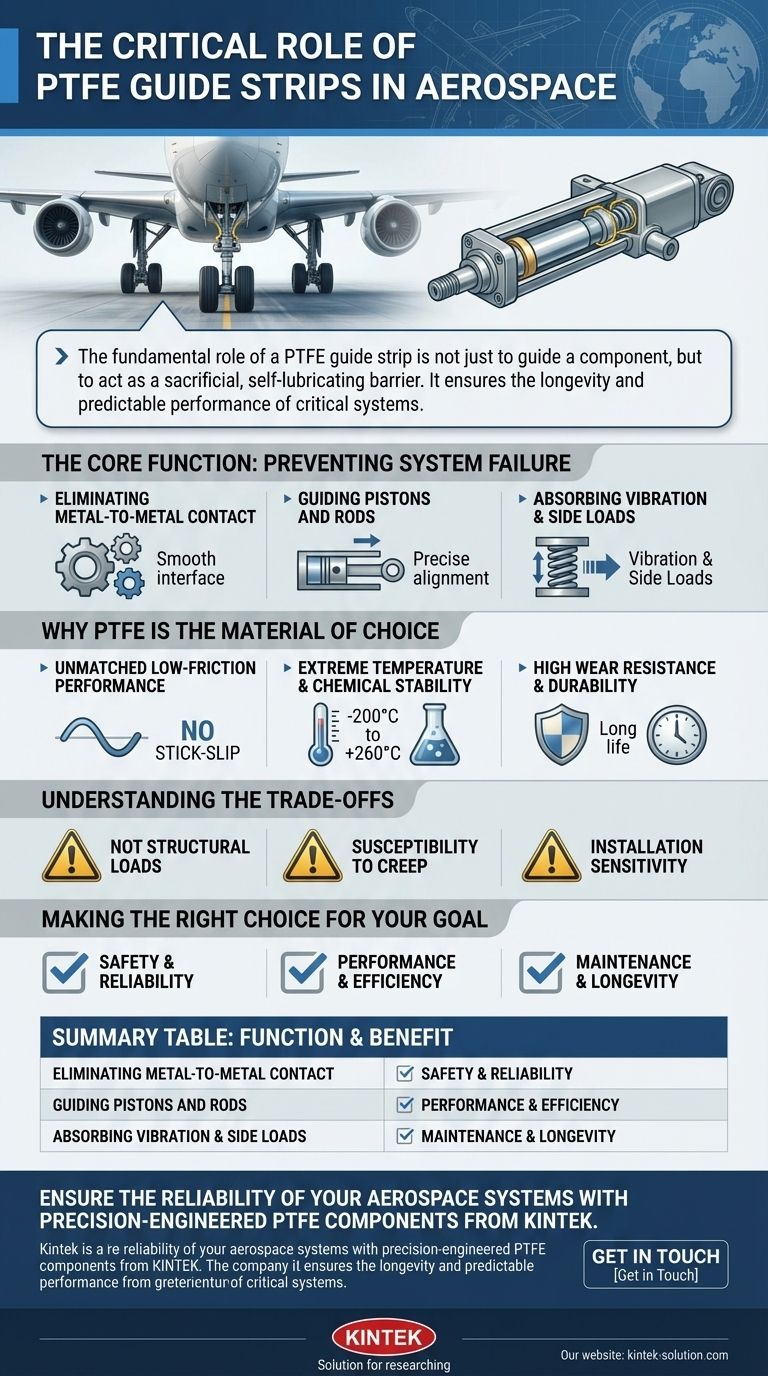

The fundamental role of a PTFE guide strip is not just to guide a component, but to act as a sacrificial, self-lubricating barrier. It ensures the longevity and predictable performance of critical systems by managing friction and preventing catastrophic wear under extreme operating conditions.

The Core Function: Preventing System Failure

In any mechanical system, the interface between moving parts is a point of potential failure. PTFE guide strips are engineered to manage this risk in high-stakes aerospace applications.

Eliminating Metal-to-Metal Contact

The primary purpose of a guide strip is to create a physical separation between a piston or rod and its housing. This prevents direct metal-on-metal friction, which can lead to galling, particle generation, and eventual seizure of the component.

By absorbing this wear, the inexpensive guide strip protects the far more costly and complex metallic components of the system.

Guiding Pistons and Rods

As their name implies, these strips guide the linear motion of components within cylinders. They ensure the piston or rod remains perfectly centered, even when subjected to significant side loads.

This precise alignment is critical for the proper function of the primary seals and the overall efficiency of the hydraulic or pneumatic actuator.

Absorbing Vibration and Side Loads

Aerospace systems are subject to immense vibration and unexpected radial (side) forces. Guide strips are manufactured with high compressive strength to absorb these loads.

This protects the primary hydraulic seals, which are designed to handle pressure but are vulnerable to damage from side-loading and eccentric movement.

Why PTFE is the Material of Choice

The selection of Polytetrafluoroethylene (PTFE) is not arbitrary; its unique molecular properties make it exceptionally well-suited for the demands of aerospace engineering.

Unmatched Low-Friction Performance

PTFE possesses one of the lowest coefficients of friction of any solid material. This self-lubricating quality is essential for smooth, efficient motion in actuators.

It specifically prevents the "stick-slip" effect, a jerky motion caused by alternating states of static and dynamic friction. Eliminating this ensures the precise and responsive operation of flight control surfaces.

Extreme Temperature and Chemical Stability

Aircraft operate in a vast range of temperatures, from freezing at high altitudes to intense heat near engines. PTFE maintains its stability and performance across this spectrum.

Furthermore, it is chemically inert, meaning it does not react with aggressive hydraulic fluids, jet fuel, or de-icing agents, preventing material degradation over time.

High Wear Resistance and Durability

While acting as a sacrificial wear component, aerospace-grade PTFE is engineered for a long service life. Its high wear and compression resistance ensure reliability between scheduled maintenance intervals, reducing aircraft downtime.

Understanding the Trade-offs

While highly effective, PTFE guide strips are not a universal solution. Understanding their limitations is key to proper engineering design.

Not Designed for Structural Loads

Guide strips are bearing elements, not structural components. They excel at managing compressive and shear forces within an assembly but cannot replace metallic parts for carrying primary structural loads.

Susceptibility to Creep

Like many polymers, PTFE can be susceptible to "creep"—a slow, permanent deformation under sustained load and temperature. This characteristic must be accounted for in the system's design tolerances to ensure long-term performance.

Installation Sensitivity

The performance of a guide strip is highly dependent on correct installation and proper sizing. An incorrect fit can lead to premature failure of the strip or the seal it is meant to protect, compromising the entire system.

Making the Right Choice for Your Goal

The application of PTFE guide strips should be directly tied to the specific engineering goal for the system.

- If your primary focus is safety and reliability: The key benefit is the prevention of metal-to-metal contact, which eliminates a primary failure mode in hydraulic actuators.

- If your primary focus is performance and efficiency: The ultra-low friction of PTFE ensures smooth, stick-slip-free actuation, enabling precise control and minimizing energy loss.

- If your primary focus is maintenance and longevity: PTFE's high wear resistance and chemical inertness provide a long, predictable service life, reducing operational costs.

Ultimately, these simple polymer strips are an indispensable technology that enables the safety, precision, and durability of modern aircraft.

Summary Table:

| Function | Benefit |

|---|---|

| Prevents Metal-to-Metal Contact | Eliminates wear, galling, and component seizure |

| Guides Pistons and Rods | Ensures precise alignment and protects primary seals |

| Absorbs Vibration and Side Loads | Protects system integrity under extreme conditions |

| Self-Lubricating (Low Friction) | Enables smooth, efficient operation and precise control |

Ensure the reliability of your aerospace systems with precision-engineered PTFE components from KINTEK.

For over [X] years, KINTEK has been a trusted partner to leading aerospace manufacturers, providing high-performance PTFE seals, guide strips, liners, and custom labware. Our components are critical for the safe and efficient operation of landing gear, flight control actuators, and other vital systems.

We specialize in custom fabrication, from rapid prototypes to high-volume production runs, ensuring a perfect fit and optimal performance for your specific application. Our expertise in material science and precision manufacturing guarantees components that meet the extreme demands of the aerospace industry.

Contact us today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How can Expanded PTFE gaskets reduce inventory complexity? Consolidate Your Stock for Greater Efficiency

- What factors are important when selecting PTFE O-ring seals? Ensure Long-Term Reliability in Harsh Environments

- What pressure ranges can PTFE energized seals withstand in aerospace applications? From Vacuum to 20,000 PSI

- What are the advantages of ceramic fillers over glass reinforcements? Superior Thermal & High-Frequency Performance

- What industries commonly use PTFE gaskets and why? Solve Demanding Sealing Challenges

- What are the most suitable PTFE grades for CNC machined parts? Achieve Optimal Performance and Durability

- What are the advantages of using ePTFE sheets for gaskets? Superior Sealing for Demanding Conditions

- How does PTFE coating improve the performance of a thrust washer? Achieve Superior Smoothness and Durability