To put it directly, glass-filled PTFE rods are a material of choice in highly demanding sectors. They are most commonly used in the aerospace, automotive, oil and gas, medical device, and electrical connector industries where standard materials fail to meet rigorous performance requirements.

The choice of glass-filled PTFE over standard PTFE isn't arbitrary; it's a strategic decision for applications that demand the chemical resilience of PTFE but with significantly improved strength, stiffness, and wear resistance.

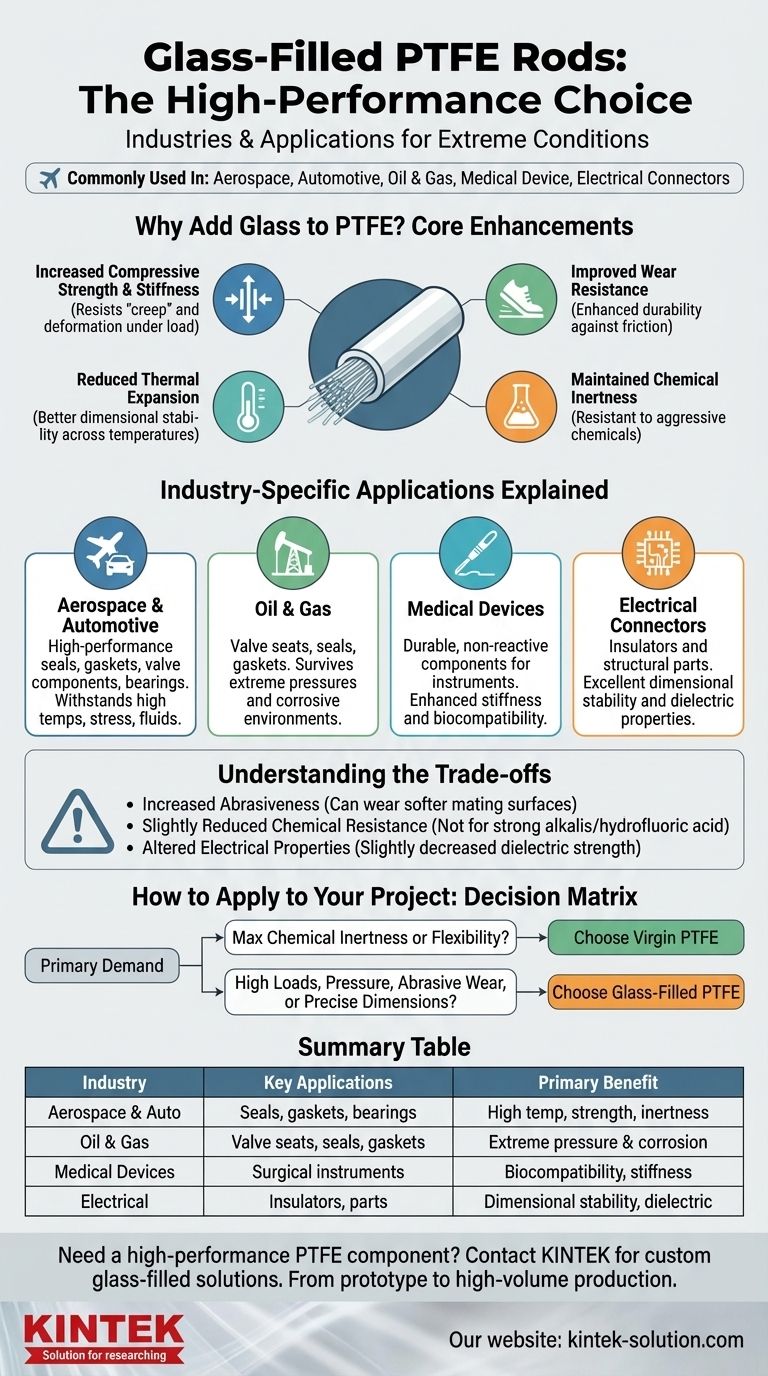

Why Add Glass to PTFE? The Core Enhancements

Understanding the industries that use this material requires understanding why glass fibers are added to Polytetrafluoroethylene (PTFE) in the first place. The glass acts as a reinforcing agent that fundamentally changes the material's mechanical properties.

Increased Compressive Strength and Stiffness

Virgin PTFE is relatively soft and can deform under load, a phenomenon known as "creep" or "cold flow." Adding glass fibers dramatically increases the material's stiffness and resistance to compression.

This makes it ideal for components that must bear weight or maintain their shape under pressure, such as seals and gaskets.

Improved Wear Resistance

The glass reinforcement significantly enhances the material's durability against friction and abrasion. This is critical for dynamic parts that slide or rotate against other surfaces.

Glass-filled PTFE lasts much longer in applications like bearings, bushings, and gears compared to its unfilled counterpart.

Reduced Thermal Expansion

A key benefit of the glass filler is improved dimensional stability. The material expands and contracts far less with temperature changes.

This property is essential for precision components in engines or sensitive equipment where even minor changes in size could lead to failure.

Maintained Chemical Inertness

While reinforcing the material, the glass fibers do not significantly compromise PTFE's legendary chemical resistance.

It remains highly effective for use with most aggressive chemicals, acids, and solvents, making it a reliable choice for harsh environments.

Industry-Specific Applications Explained

The enhanced properties of glass-filled PTFE make it a problem-solver in several key industries.

Aerospace and Automotive

In these sectors, components must withstand high temperatures, mechanical stress, and chemical exposure from fuels and fluids.

Glass-filled PTFE is used for high-performance seals, gaskets, valve components, and bearings that require unwavering reliability.

Oil and Gas

The oil and gas industry demands materials that can survive extreme pressures and highly corrosive chemical environments.

Its combination of chemical inertness and compressive strength makes glass-filled PTFE perfect for valve seats, seals, and gaskets used in extraction and processing equipment.

Medical Devices

While standard PTFE is known for its biocompatibility, the added stiffness and wear resistance of the glass-filled version are valuable for certain devices.

It is used to create durable, non-reactive components for surgical instruments and other long-lasting medical equipment.

Electrical Connectors and Insulators

In electronics, components must often hold their shape precisely while providing excellent electrical insulation.

The dimensional stability and dielectric properties of glass-filled PTFE make it a superior choice for high-quality insulators and structural parts within complex electrical connectors.

Understanding the Trade-offs

No material is perfect. Opting for glass-filled PTFE involves accepting a few specific trade-offs compared to virgin PTFE.

Increased Abrasiveness

The hard glass fibers that provide wear resistance can, in turn, accelerate wear on softer mating surfaces, such as shafts made from aluminum or softer steels. This must be considered in any system design.

Slightly Reduced Chemical Resistance

While still excellent, glass-filled PTFE is not recommended for use with strong alkalis or hydrofluoric acid. These specific chemicals can attack the glass filler, compromising the material's integrity.

Altered Electrical Properties

The addition of glass can slightly decrease the dielectric strength of PTFE. For the most demanding high-voltage insulation applications, virgin PTFE may still be the preferred choice.

How to Apply This to Your Project

Choosing the right material depends entirely on the primary demands of your application.

- If your primary focus is maximum chemical inertness or flexibility: Virgin PTFE is likely the better and more cost-effective choice.

- If your application involves high loads, pressure, or abrasive wear: Glass-filled PTFE provides the necessary mechanical strength that virgin PTFE lacks.

- If your component must maintain precise dimensions across temperature changes: The reduced thermal expansion of glass-filled PTFE makes it the superior option.

- If your design involves a soft metal mating surface: Consider a different filler (like bronze or carbon) or use virgin PTFE to avoid accelerated wear on the mating part.

Ultimately, selecting glass-filled PTFE is an engineering decision to gain mechanical robustness without sacrificing the core chemical advantages of PTFE.

Summary Table:

| Industry | Key Applications | Primary Benefit of Glass-Filled PTFE |

|---|---|---|

| Aerospace & Automotive | Seals, gaskets, bearings, valve components | High temperature resistance, mechanical strength, and chemical inertness |

| Oil & Gas | Valve seats, seals, gaskets | Extreme pressure and corrosion resistance |

| Medical Devices | Surgical instruments, durable equipment components | Biocompatibility with enhanced stiffness and wear resistance |

| Electrical Connectors | Insulators, structural parts | Excellent dimensional stability and dielectric properties |

Need a high-performance PTFE component that can handle extreme conditions?

At KINTEK, we specialize in the precision manufacturing of PTFE components, including custom glass-filled formulations. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we can help you select the right material and fabricate the perfect part—from prototype to high-volume production.

Contact our experts today to discuss how our custom PTFE solutions can enhance the strength, durability, and reliability of your application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications