To be clear, PTFE-free bushings are most frequently specified in the automotive, aerospace, and heavy industrial machinery sectors. These industries value them for their ability to handle extreme temperatures and pressures, especially in applications where external lubrication is present or where emerging environmental regulations are a primary concern.

The decision to use a PTFE-free bushing is rarely about a single property. It's about addressing specific operational challenges or regulatory constraints where traditional PTFE components fall short, such as the need for radiation resistance or compliance with future PFAS chemical bans.

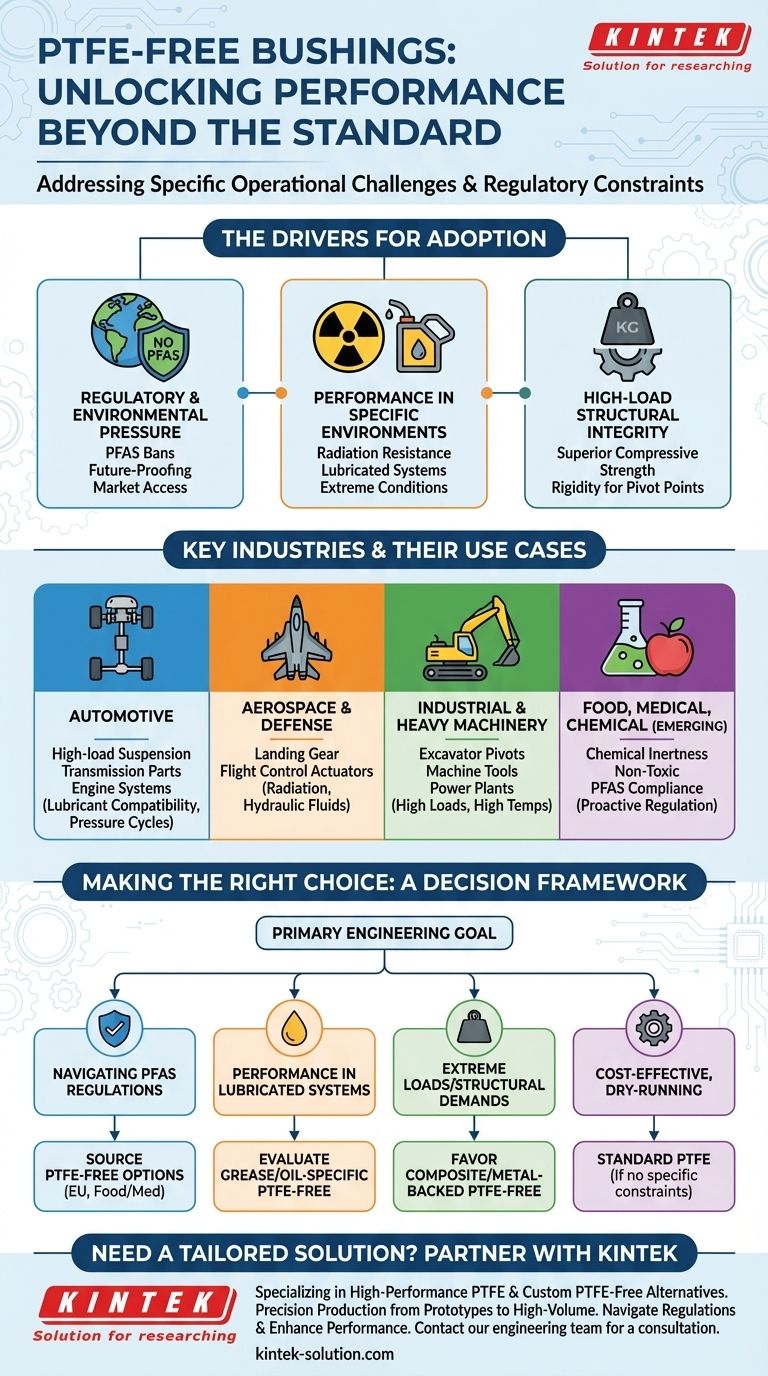

The Drivers for Adopting PTFE-Free Solutions

While PTFE bushings are an industry standard known for excellent performance, several key factors are driving engineers to seek alternatives. Understanding these drivers is critical to making the right component choice.

Regulatory and Environmental Pressure

The most significant driver is the increasing regulation of per- and polyfluoroalkyl substances (PFAS). PTFE is a type of PFAS, and mounting environmental and health concerns are leading to stricter controls, particularly in Europe.

Industries that export globally or operate in sensitive sectors like food processing and medical devices are proactively seeking PTFE-free alternatives to future-proof their products and maintain market access.

Performance in Specific Environments

PTFE has well-known operational limits. For instance, it has poor resistance to radiation, making it less suitable for applications in nuclear power plants or aerospace systems exposed to cosmic rays.

Furthermore, while PTFE excels in dry-running conditions, some PTFE-free materials are engineered specifically to thrive in heavily lubricated environments, potentially offering a longer service life in systems flooded with oil or grease.

High-Load Structural Integrity

Many PTFE-free bushings are composite designs, such as fiber-wound or metal-backed polymer bearings. These constructions can offer superior compressive strength and rigidity compared to homogenous PTFE bushings.

This makes them a preferred choice for high-load pivot points in construction equipment, agricultural machinery, and industrial presses where structural integrity under immense pressure is the primary requirement.

Key Industries and Their Use Cases

The choice of a bushing material is dictated by the precise demands of the application. Here is how different industries leverage PTFE-free technology.

Automotive Sector

While PTFE is widely used for seals and gaskets, PTFE-free bushings are specified for high-load suspension components, transmission parts, and engine systems where compatibility with lubricants and resistance to extreme pressure cycles are critical.

Aerospace and Defense

In aerospace, PTFE is a go-to for many low-friction bearings. However, PTFE-free alternatives are selected for components in landing gear, flight control actuators, and systems exposed to radiation or requiring compatibility with specific hydraulic fluids.

Industrial and Heavy Machinery

This is a primary market for robust PTFE-free bushings. Applications include pivot points on excavators, bearings in manufacturing machine tools, and components in thermal power plants where high loads and high temperatures are constant.

Emerging Opportunities: Food, Medical, and Chemical

Historically, these industries have relied heavily on PTFE for its chemical inertness and non-toxic properties. However, due to the regulatory pressure on PFAS, they represent a significant growth area for PTFE-free alternatives. The challenge is validating new materials that offer the same level of safety, non-reactivity, and compliance.

Understanding the Trade-offs

Choosing a PTFE-free bushing means weighing its advantages against the proven performance of the industry standard. Objectivity is crucial.

The Performance Benchmark of PTFE

PTFE sets a high bar. Its extremely low coefficient of friction, wide operating temperature range, and chemical inertness make it an exceptional material for maintenance-free, dry-running applications. It remains the default choice for a vast number of uses.

When a PTFE-Free Bushing Is Not the Best Fit

If your application is a straightforward dry-running, low-friction mechanism with no extreme loads and no regulatory pressure regarding PFAS, a standard PTFE bushing is often the most cost-effective and reliable solution. A PTFE-free alternative may introduce higher friction or unnecessary cost.

"PTFE-Free" Is a Category, Not a Single Material

It is critical to remember that "PTFE-free" describes what a material is not, not what it is. This category includes everything from fiber-wound composite bearings to bushings made from other polymers like PEEK or polyamides, each with a unique performance profile. The choice must be based on the specific material's data sheet, not the general category.

Making the Right Choice for Your Application

Your final decision should be guided by your primary engineering or business goal.

- If your primary focus is navigating PFAS regulations: Prioritize sourcing and validating PTFE-free options, especially for products intended for the European market or in the food and medical industries.

- If your primary focus is performance in a lubricated system: Evaluate PTFE-free bushings specifically designed to work with grease or oil, as they may offer a longer service life than PTFE in that environment.

- If your primary focus is extreme loads or structural demands: Favor fiber-wound or metal-backed composite bushings, which are typically PTFE-free and offer superior compressive strength.

- If your primary focus is cost-effective, dry-running performance: A standard PTFE bushing remains an excellent choice, provided there are no specific regulatory or environmental constraints.

Ultimately, the best bushing is the one whose material properties precisely match the complex demands of your specific application.

Summary Table:

| Industry | Primary Use Cases | Key Driver |

|---|---|---|

| Automotive | High-load suspension, transmission parts | Extreme pressure cycles, lubricant compatibility |

| Aerospace & Defense | Landing gear, flight control actuators | Radiation resistance, hydraulic fluid compatibility |

| Heavy Machinery | Excavator pivots, machine tools, power plants | High structural loads, high temperatures |

| Food, Medical, Chemical | Components requiring chemical inertness | Proactive compliance with PFAS regulations |

Need a PTFE-Free Bushing Solution Tailored to Your Industry?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom PTFE-free alternatives for demanding applications. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a bushing that meets your exact operational and regulatory needs.

Let us help you navigate PFAS regulations and enhance your equipment's performance. Contact our engineering team today for a consultation on your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE gaskets ideal for marine applications? Superior Sealing for Harsh Saltwater Environments

- What are the shapes and dimensions of PTFE sliding bearing pads? Rectangular & Circular Load Solutions

- What is the role of PTFE backup rings in sealing applications? Prevent Seal Extrusion Under High Pressure

- Why is PTFE's chemical resistance significant for shaft seals? Ensuring Leak-Free Performance in Harsh Environments

- What are the different grades of Teflon (PTFE) and their applications? A Guide to Material Selection

- What advantages does PTFE offer in automotive applications? Enhance Vehicle Efficiency and Durability

- What are the key benefits of using PTFE in CNC machining? Achieve Unmatched Performance in Harsh Environments

- How do PTFE piston rings achieve sealing without additional components? Discover the Self-Clamping Principle