In short, a PTFE backup ring is a support component that prevents a softer, primary seal—like a rubber O-ring—from being squeezed out of its designated groove under high pressure. It is not the seal itself, but rather a rigid reinforcement that sits alongside the primary seal, physically blocking the path of extrusion and dramatically increasing the sealing system's pressure and temperature capabilities.

The fundamental role of a PTFE backup ring is to add mechanical strength to a sealing system. It acts as a barrier, mitigating the primary failure mode of soft seals in high-pressure environments, which is extrusion into the clearance gap between metal components.

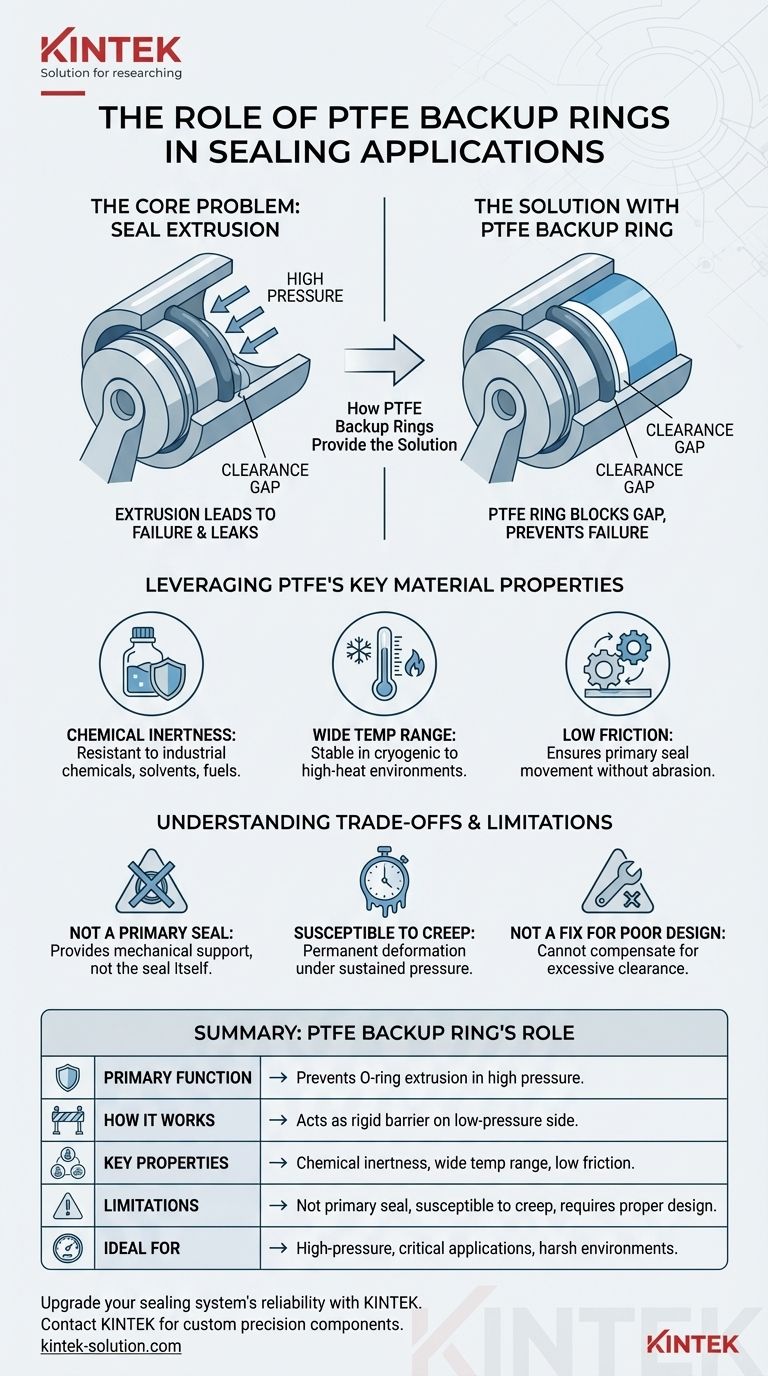

The Core Problem: Seal Extrusion

To understand the value of a backup ring, you must first understand the problem it solves: the physical failure of a primary seal.

What is Seal Extrusion?

In any sealing application, a small clearance gap exists between the moving and stationary parts (e.g., between a piston and a cylinder wall).

When pressure is applied, it pushes on the primary seal (the O-ring). Under high pressure, this force can be enough to squeeze the soft, flexible material of the O-ring into the narrow clearance gap. This phenomenon is called extrusion.

Why Extrusion Leads to Failure

Once the seal material is forced into the gap, it is quickly damaged, nibbled away, or sheared off by the sharp edges of the hardware.

This damage compromises the seal, leading directly to leaks and, eventually, a complete failure of the sealing system.

How PTFE Backup Rings Provide the Solution

A PTFE backup ring is a simple yet highly effective device engineered to prevent extrusion by leveraging the unique properties of Polytetrafluoroethylene (PTFE).

Bridging the Extrusion Gap

The backup ring is installed in the gland on the low-pressure side of the O-ring. Because PTFE is a significantly harder and more rigid material than the elastomer O-ring, it does not deform easily.

It sits securely in the groove and physically blocks the clearance gap, preventing the softer O-ring material from being forced into it.

Leveraging PTFE's Key Material Properties

PTFE is an ideal material for this role due to a combination of beneficial characteristics.

- Chemical Inertness: PTFE is resistant to nearly all industrial chemicals, solvents, acids, and fuels. This ensures the backup ring will not degrade even in chemically aggressive environments.

- Wide Temperature Range: PTFE maintains its strength and stability across an exceptionally broad temperature range, from cryogenic lows to high-heat applications, providing consistent support where elastomers might fail.

- Low Friction: The extremely low coefficient of friction of PTFE is critical. It ensures that the primary seal can be energized and move slightly under pressure cycles without being abraded or damaged by the backup ring itself.

Understanding the Trade-offs and Limitations

While highly effective, it's crucial to recognize that a PTFE backup ring is a specialized component, not a universal fix for all sealing issues.

Backup Ring vs. Primary Seal

A common misconception is that the backup ring itself provides the seal. It does not. Its purpose is purely mechanical support.

The flexible, compliant O-ring provides the actual seal against the hardware surfaces. The backup ring simply ensures the O-ring can continue doing its job under high pressure.

Susceptibility to Creep

While strong, pure PTFE can be susceptible to creep—a slow, permanent deformation under sustained pressure and temperature.

For very high-pressure or high-temperature static applications, filled PTFE grades (mixed with materials like carbon or glass) are often used to improve creep resistance and compressive strength.

Not a Cure for Poor Gland Design

Backup rings are designed to enhance the performance of a properly designed system. They cannot compensate for excessive clearance gaps or an incorrectly specified primary seal.

If the extrusion gap is too large, even a backup ring may eventually be forced into it, leading to failure.

When to Specify a PTFE Backup Ring

Your decision to use a backup ring should be based on the operational demands of your application.

- If your primary focus is high-pressure performance: A backup ring is essential for preventing seal extrusion in hydraulic cylinders, pumps, and valves operating at pressures where a standard O-ring would fail.

- If your primary focus is system reliability: Adding a backup ring is a cost-effective method for extending the service life and maintenance intervals of seals in demanding or critical applications.

- If your primary focus is chemical and thermal stability: The inherent properties of PTFE ensure the support structure for your seal remains intact in environments that would degrade other materials.

By adding this simple component, you are fundamentally upgrading the mechanical robustness of your entire sealing system.

Summary Table:

| Aspect | PTFE Backup Ring's Role |

|---|---|

| Primary Function | Prevents soft O-ring extrusion into the clearance gap under high pressure. |

| How It Works | Acts as a rigid barrier on the low-pressure side of the O-ring. |

| Key Material Properties | Chemical inertness, wide temperature range, and low friction. |

| Limitations | Does not provide the seal itself; susceptible to creep in pure form; cannot fix poor gland design. |

| Ideal For | High-pressure systems, critical/reliable applications, and harsh chemical/thermal environments. |

Upgrade your sealing system's reliability and pressure rating with precision-engineered PTFE components from KINTEK.

Whether you are designing for the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE backup rings, seals, liners, and labware are manufactured to the highest standards of precision. We partner with you from prototype to high-volume production to ensure your application performs flawlessly under extreme conditions.

Contact KINTEK today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications