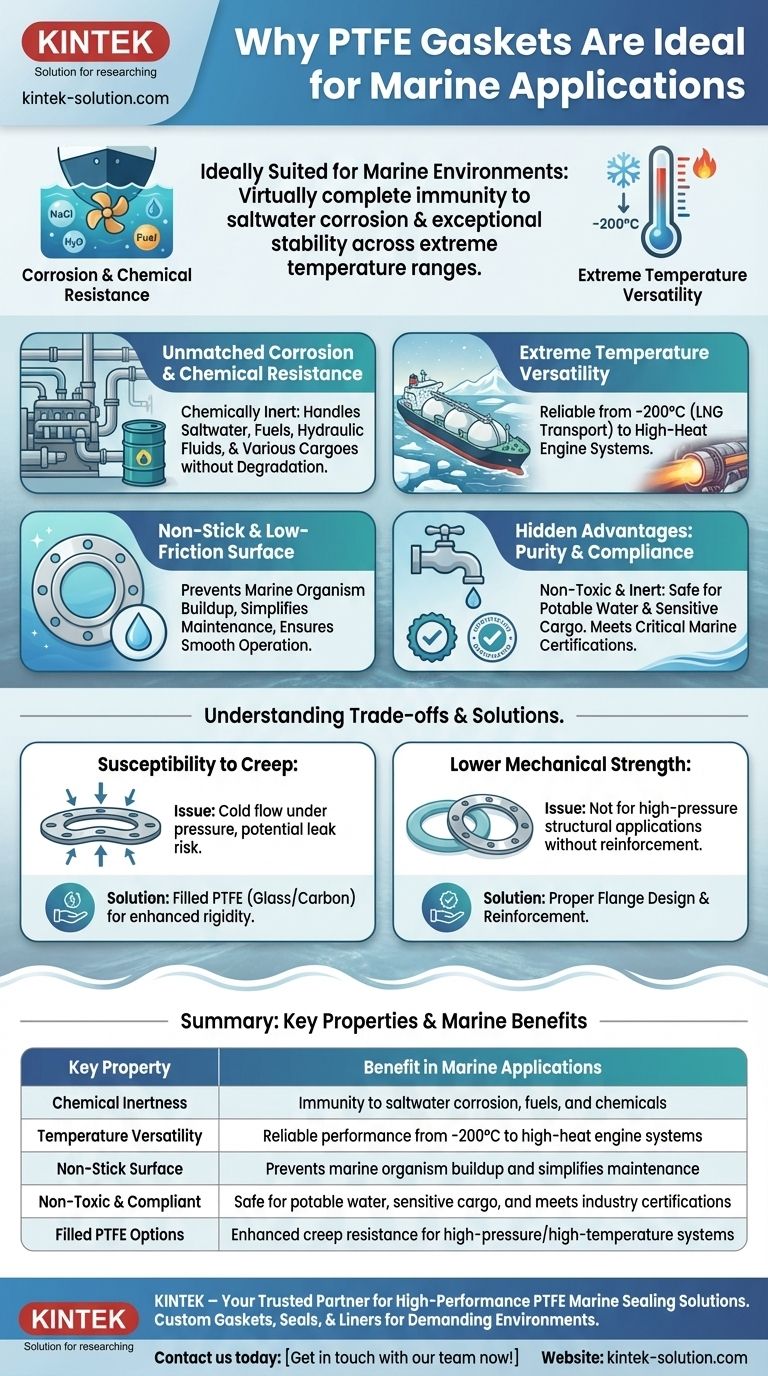

In short, PTFE gaskets are ideal for marine applications due to their virtually complete immunity to saltwater corrosion and their exceptional stability across the extreme temperature ranges found on modern vessels. From cryogenic LNG transport to high-heat engine systems, PTFE provides a reliable, long-lasting seal in an environment that quickly degrades lesser materials.

The core reason for PTFE's dominance in marine settings is not a single feature, but its unique combination of properties. It simultaneously solves the challenges of chemical attack from saltwater, operational temperature extremes, and the need for material purity in critical systems.

The Unyielding Defense Against the Marine Environment

To understand why PTFE is the go-to choice, we must look at the specific challenges of the marine world and how PTFE's intrinsic properties provide a direct solution.

Unmatched Corrosion and Chemical Resistance

The most significant threat in any marine application is saltwater corrosion. PTFE (Polytetrafluoroethylene) is chemically inert, meaning it does not react with corrosive salts, acids, or alkalis.

This resistance extends beyond saltwater. PTFE gaskets safely handle the wide array of substances found on a vessel, including fuels, hydraulic fluids, lubricants, and various chemical cargoes without degrading.

Extreme Temperature Versatility

A marine vessel is a machine of extremes. PTFE gaskets perform reliably across this entire operational spectrum.

They maintain their integrity and sealing capability in high-temperature environments like engine rooms and exhaust systems. At the same time, they exhibit superb performance in cryogenic conditions as low as -200°C (-328°F), making them essential for sealing systems on liquefied natural gas (LNG) carriers.

Non-Stick and Low-Friction Surface

The non-stick surface of PTFE, famous for its use in cookware, offers significant practical advantages in marine engineering.

This property prevents the buildup of marine organisms and other deposits, simplifying maintenance and ensuring clean flange surfaces. In dynamic applications like valve seats, its low coefficient of friction ensures smooth, reliable operation with minimal wear.

The Hidden Advantages: Purity and Compliance

Beyond raw performance, PTFE meets other critical requirements for safety and regulation at sea.

Chemically Inert and Non-Toxic

Because PTFE is inert and non-toxic, it will not contaminate the substances it comes into contact with. This is crucial for systems handling potable water, foodstuffs, or other sensitive cargo.

Meeting Critical Certifications

The harsh and regulated nature of the marine industry, from commercial shipping to offshore oil rigs, requires materials that meet stringent safety and performance certifications. PTFE's well-documented stability and reliability make it a trusted material that consistently satisfies these regulatory demands.

Understanding the Trade-offs

No material is perfect. While PTFE is an exceptional choice, it's critical to be aware of its mechanical limitations to ensure proper application.

Susceptibility to Creep

PTFE can be susceptible to "creep," or cold flow, where the material slowly deforms under sustained pressure. This is more pronounced at higher temperatures and can lead to a loss of bolt torque and potential leaks over time.

To counteract this, filled PTFE variants (mixed with materials like glass fiber or carbon) are often used to enhance rigidity and resistance to creep in high-pressure or high-temperature applications.

Lower Mechanical Strength

Compared to metals or harder plastics, pure PTFE is a relatively soft material. This makes it unsuitable for extremely high-pressure structural applications without reinforcement or proper flange design to contain the gasket.

Making the Right Choice for Your Application

Selecting the correct gasket depends entirely on the specific system's operational demands.

- If your primary focus is general-purpose sealing (seawater, fuel, bilge): Standard, pure PTFE offers the perfect balance of chemical resistance and cost-effectiveness.

- If you are sealing a high-pressure or high-temperature system (engine room, steam lines): Choose a filled PTFE gasket (e.g., glass or carbon-filled) to improve creep resistance and mechanical stability.

- If your application involves cryogenic fluids (LNG/LPG transport): Pure PTFE is the ideal choice due to its outstanding flexibility and sealing performance at extremely low temperatures.

Ultimately, understanding these core properties empowers you to select a gasket that guarantees long-term safety, reliability, and operational efficiency at sea.

Summary Table:

| Key Property | Benefit in Marine Applications |

|---|---|

| Chemical Inertness | Immunity to saltwater corrosion, fuels, and chemicals |

| Temperature Versatility | Reliable performance from -200°C to high-heat engine systems |

| Non-Stick Surface | Prevents marine organism buildup and simplifies maintenance |

| Non-Toxic & Compliant | Safe for potable water, sensitive cargo, and meets industry certifications |

| Filled PTFE Options | Enhanced creep resistance for high-pressure/high-temperature systems |

Need a reliable sealing solution for your marine application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gaskets, seals, and liners tailored for the demanding environments of the marine, semiconductor, medical, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal that withstands saltwater, extreme temperatures, and regulatory requirements.

Contact us today to discuss your specific needs and let our experts provide a solution that enhances your vessel's safety and operational efficiency. Get in touch with our team now!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions