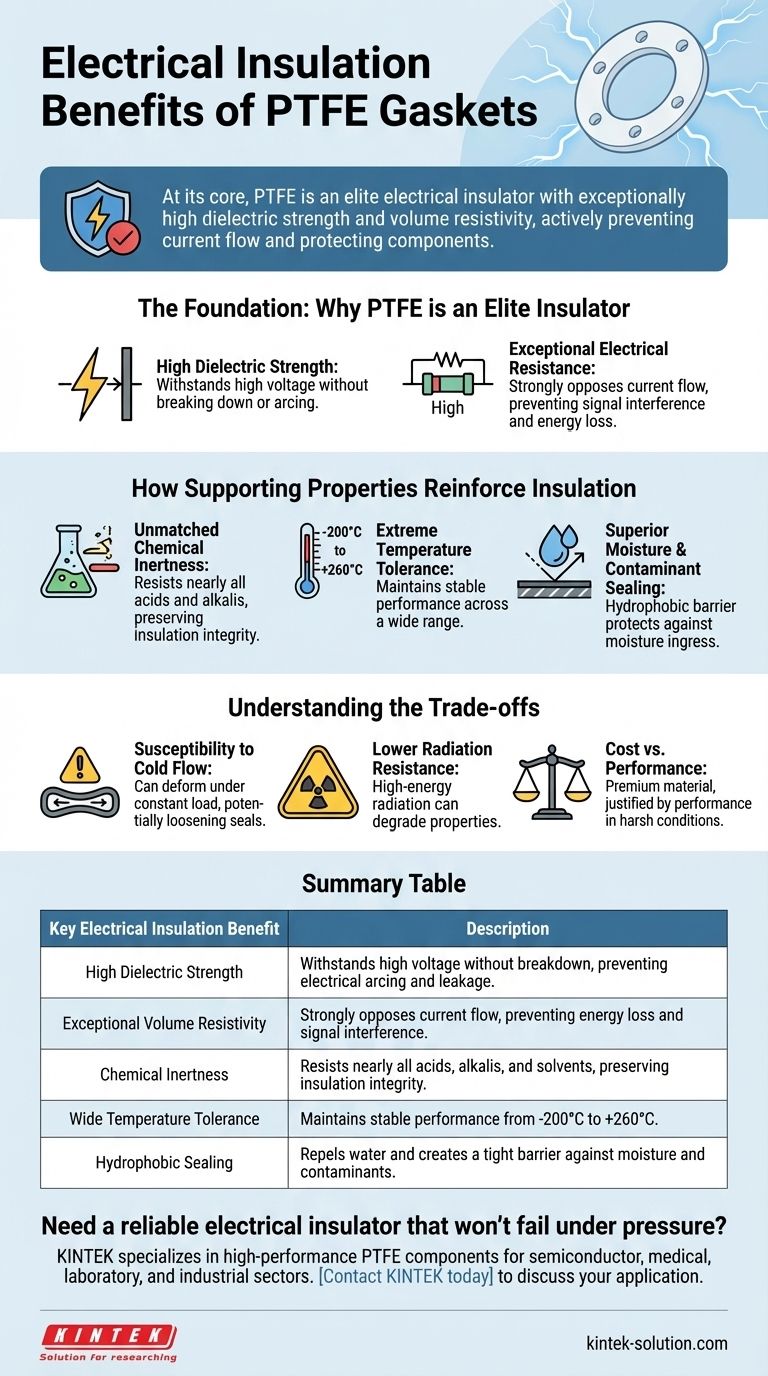

At its core, Polytetrafluoroethylene (PTFE) is one of the most effective and reliable electrical insulators used in modern engineering. Its primary benefit is an exceptionally high dielectric strength and volume resistivity, which actively prevents the flow of electrical current and protects sensitive components from leakage and short-circuiting.

The true value of PTFE as an electrical insulator is not just its inherent ability to resist electricity. It's the fact that this elite insulating property is fiercely protected by its legendary resistance to chemicals, moisture, and extreme temperatures, ensuring reliable performance in environments where other materials would quickly fail.

The Foundation: Why PTFE is an Elite Insulator

The electrical benefits of PTFE gaskets stem from the material's unique molecular structure. This structure is responsible for its high performance as a dielectric material.

High Dielectric Strength

Dielectric strength is the measure of a material's ability to withstand a high voltage without breaking down and conducting electricity. PTFE possesses a very high dielectric strength, making it an ideal barrier to prevent electrical arcing or leakage between conductive components.

Exceptional Electrical Resistance

PTFE has an extremely high volume resistivity, meaning it strongly opposes the flow of electrical current through its bulk. This property is critical for applications where even minuscule current leaks could cause signal interference, energy loss, or safety hazards.

How Supporting Properties Reinforce Insulation

An insulator is only as good as its ability to survive its operating environment. PTFE's other well-known characteristics are what make its electrical properties so dependable in the real world.

Unmatched Chemical Inertness

Many chemicals are corrosive and can degrade insulating materials, compromising their electrical properties over time. PTFE is famously inert to nearly all acids, alkalis, and solvents, ensuring that its insulating capabilities remain fully intact even in highly corrosive settings.

Extreme Temperature Tolerance

Electrical resistance can change significantly with temperature. PTFE gaskets maintain their excellent insulating properties across an exceptionally wide temperature range, from cryogenic conditions (-200°C) up to high heat (+260°C). This stability guarantees predictable performance where other plastics would melt, degrade, or become brittle.

Superior Moisture and Contaminant Sealing

Moisture and dust are primary causes of electrical failure. PTFE is hydrophobic (it repels water) and its conformability allows it to create a tight, durable seal. This physical barrier protects sensitive electronics from moisture ingress and contamination that could otherwise create a path for current and cause a short circuit.

Understanding the Trade-offs

While PTFE is an exceptional material, no single solution is perfect for every scenario. Acknowledging its limitations is key to proper application.

Susceptibility to Cold Flow

Pure, unfilled PTFE can be prone to "creep" or cold flow. When placed under a constant compressive load, the material can slowly deform over time. This could potentially loosen the seal, compromising the environmental protection that is critical for the components inside.

Lower Radiation Resistance

Compared to some other polymers, PTFE can be degraded by high-energy radiation, such as gamma or electron-beam radiation. In these specific environments, its molecular structure can break down, leading to a loss of both mechanical and electrical properties.

Cost vs. Performance

PTFE is a premium performance polymer, and its cost is generally higher than that of more common sealing materials. The investment is justified by its unparalleled performance in harsh conditions where failure is not an option.

Making the Right Choice for Your Goal

To select the right gasket, you must evaluate the entire operating environment, not just the electrical requirements.

- If your primary focus is insulation in a chemically aggressive or high-temperature environment: PTFE is one of the most reliable choices you can make, as its properties will not degrade.

- If your primary focus is preventing moisture ingress for sensitive electronics: PTFE's combination of excellent sealing and inherent water repellency offers a superior level of protection.

- If your application involves high mechanical pressure and risk of creep: Consider a "filled" PTFE gasket, which incorporates materials like glass or carbon to improve its mechanical strength and resistance to cold flow.

Ultimately, choosing PTFE for electrical insulation provides confidence that your system is protected by a material that excels not only electrically but also environmentally and thermally.

Summary Table:

| Key Electrical Insulation Benefit | Description |

|---|---|

| High Dielectric Strength | Withstands high voltage without breakdown, preventing electrical arcing and leakage. |

| Exceptional Volume Resistivity | Strongly opposes current flow, preventing energy loss and signal interference. |

| Chemical Inertness | Resists nearly all acids, alkalis, and solvents, preserving insulation integrity. |

| Wide Temperature Tolerance | Maintains stable performance from -200°C to +260°C. |

| Hydrophobic Sealing | Repels water and creates a tight barrier against moisture and contaminants. |

Need a reliable electrical insulator that won't fail under pressure?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, gaskets, liners, and custom labware. We serve the semiconductor, medical, laboratory, and industrial sectors, where precision and reliability are non-negotiable. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a PTFE solution tailored to your specific electrical insulation and environmental challenges.

Contact KINTEK today to discuss how our PTFE components can protect your critical applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the installation methods for PTFE slide bearings? Bolting, Welding & Mortar Embedment

- How is a PTFE bearing pad installed on prefabricated beams? A Guide to Secure, Low-Friction Installation

- What temperature range can PTFE oil seals withstand? From -200°C to +260°C for Extreme Applications

- How can PTFE be modified to enhance its sealing properties? Boost Durability & Performance

- Which substances is PTFE not chemically resistive to? Avoid These Extreme Conditions

- What role do PTFE tri-clamp gaskets play in industrial applications? Ensuring Leak-Proof, Contamination-Free Systems

- What are PTFE Teflon washers? The Ultimate Guide to High-Performance Sealing

- What temperature range can PTFE bushes withstand? From Cryogenic -200°C to High-Heat 260°C