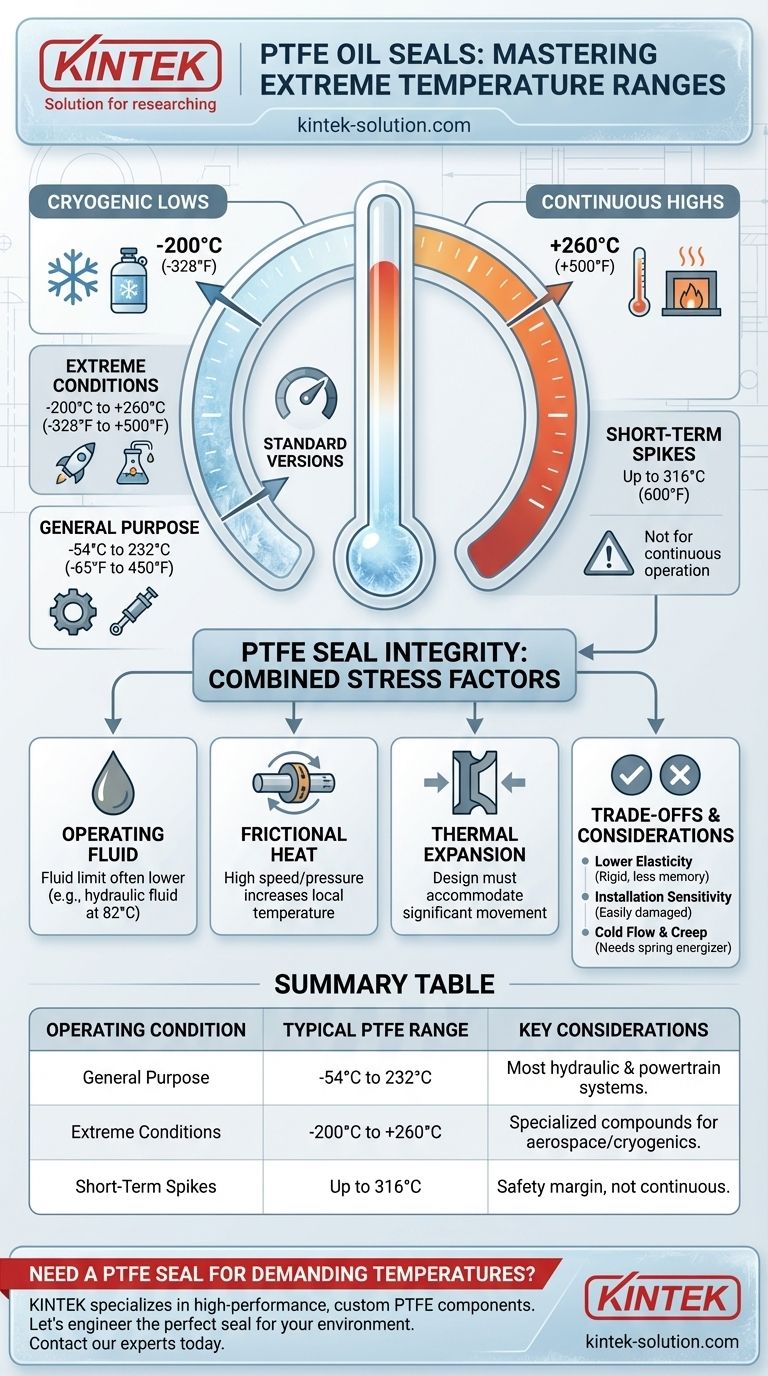

At a fundamental level, PTFE oil seals are known for their exceptionally wide operating temperature range. They can typically function effectively from cryogenic lows of -200°C (-328°F) up to continuous high temperatures of 260°C (500°F). However, the precise range for a specific seal often depends on the exact PTFE compound and the seal's design, with standard versions commonly rated for a slightly narrower, yet still impressive, window.

The standout temperature resistance of PTFE is its defining feature, but its real-world effectiveness is not just about survival. It's about maintaining seal integrity under the combined stress of temperature, pressure, rotational speed, and the fluid being sealed.

Deconstructing the PTFE Temperature Spectrum

To select the right seal, you must understand that not all PTFE is created equal. The broad temperature range often quoted applies to the base material, but practical application requires more specific knowledge.

The General-Purpose Range

For most standard PTFE lip seals used in common industrial applications, a more conservative and realistic operating range is -54°C to 232°C (-65°F to 450°F). This range covers the vast majority of hydraulic and powertrain systems while providing a significant performance advantage over traditional rubber seals.

Specialized Compounds for Extreme Conditions

The full -200°C to +260°C (-328°F to +500°F) range is achievable with specialized PTFE compounds. These are often used in demanding aerospace, chemical processing, or cryogenic applications where no other material can perform. These grades maintain their core properties even at temperatures that would cause elastomers to become brittle or melt.

Handling Short-Term Temperature Spikes

Some high-performance PTFE seals are engineered to withstand brief temperature excursions up to 316°C (600°F). This capability provides a critical safety margin in systems prone to temporary overheating, but it is not intended for continuous operation at this level.

Beyond Temperature: Factors That Define Performance

A seal's temperature rating is only part of the story. In any dynamic system, other forces are at play that can affect the seal's longevity and effectiveness.

The System's Operating Fluid

The fluid being sealed often has a much lower temperature limit than the PTFE seal itself. For instance, standard hydraulic fluid performs best below 60-82°C (140-180°F) to prevent oxidation and viscosity breakdown. A PTFE seal can easily survive 200°C, but the system will have failed long before that if the fluid degrades.

Frictional Heat from Pressure and Speed

High rotational speeds and system pressures generate significant frictional heat directly at the point of contact between the seal lip and the shaft. This localized heat adds to the ambient system temperature. The total temperature at the seal lip must remain within the PTFE's operational limits to prevent premature wear.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. This means it expands and contracts significantly with temperature changes. The housing and gland design must account for this movement to ensure the seal maintains the correct interference and contact pressure with the shaft across the entire operating temperature range.

Understanding the Trade-offs of PTFE Seals

While its thermal stability is unmatched, PTFE is not the default choice for every application. Its unique properties come with specific trade-offs compared to traditional elastomeric (rubber) seals.

Lower Elasticity

PTFE is a thermoplastic, not an elastomer. It is more rigid and has very little "memory" or bounce-back compared to rubber. This makes it less forgiving of shaft imperfections, surface finish irregularities, or significant dynamic runout.

Installation Sensitivity

Due to its rigidity, a PTFE seal lip can be more easily nicked, scratched, or permanently deformed during installation if not handled with care. Proper installation tools and procedures are critical to creating an effective, leak-free seal.

Cold Flow and Creep

Under a constant load (like the interference fit on a shaft), PTFE can be prone to "cold flow" or creep over time, which can slowly reduce the sealing force. This is often managed by incorporating a metallic spring energizer into the seal design, which provides a constant elastic force to maintain lip pressure.

Making the Right Choice for Your Application

Selecting the correct seal material requires you to look at the complete operational environment, not just one parameter.

- If your primary focus is extreme temperature stability: A specialized PTFE seal is an excellent choice, but you must verify the specific compound's rating is sufficient for your exact high or low-temperature needs.

- If you are designing a standard industrial gearbox or hydraulic system: A standard PTFE seal offers a superb safety margin, but remember the fluid's own temperature limit is often the more critical factor for system longevity.

- If your application involves high shaft runout or a poor surface finish: A more flexible elastomeric seal, like FKM (Viton®), might provide a more reliable seal than rigid PTFE, provided its more limited temperature range is acceptable.

Ultimately, understanding these factors allows you to choose a seal based not just on a datasheet number, but on the total performance requirements of your system.

Summary Table:

| Operating Condition | Typical PTFE Seal Temperature Range | Key Considerations |

|---|---|---|

| General Purpose | -54°C to 232°C (-65°F to 450°F) | Covers most hydraulic and powertrain systems. |

| Extreme Conditions | -200°C to +260°C (-328°F to +500°F) | Requires specialized compounds for aerospace/cryogenics. |

| Short-Term Spikes | Up to 316°C (600°F) | Not for continuous operation; provides a safety margin. |

Need a PTFE Seal for Demanding Temperatures?

Your application's success depends on a seal that can handle the heat—and the cold. KINTEK specializes in manufacturing high-performance, custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors.

We deliver precision-engineered solutions that maintain integrity under extreme thermal stress, pressure, and speed. From initial prototypes to high-volume production, our expertise ensures your system operates reliably.

Let's engineer the perfect seal for your environment. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is Teflon coating popular in the food processing industry? Boost Efficiency & Product Quality

- What are the main differences between RPTFE and standard PTFE for valve seats? Choose the Right Material for Your System

- How do PTFE oil seals perform in terms of cleanliness and compliance? Ensure Purity in Critical Applications

- What are the challenges in manufacturing PTFE impellers? Overcoming the Complexities of Machining

- How does temperature tolerance differ between NBR and PTFE seat materials? A Guide to Extreme Conditions

- What makes Teflon plastic sheets versatile across industries? The Ultimate High-Performance Solution

- Why are PTFE bellows preferred in the food, dairy, and pharmaceutical industries? Ensure Uncompromising Product Purity and Safety

- What advantages do PTFE washers offer? Superior Chemical, Thermal, and Low-Friction Performance