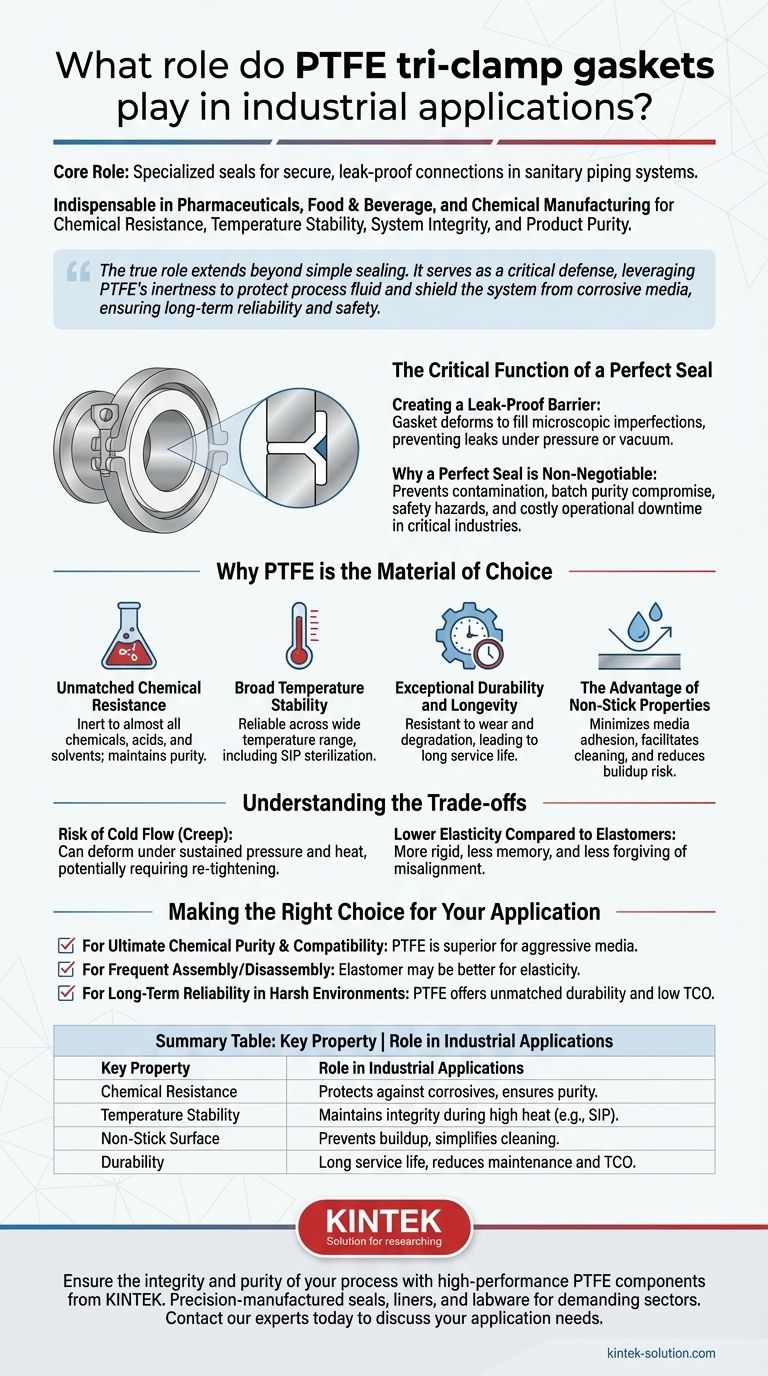

At their core, PTFE tri-clamp gaskets are specialized seals designed to create secure, leak-proof connections within sanitary piping systems. They are indispensable in demanding industries like pharmaceuticals, food and beverage, and chemical manufacturing due to their exceptional chemical resistance and temperature stability, which guarantee system integrity and product purity.

The true role of a PTFE tri-clamp gasket extends beyond simple sealing. It serves as a critical point of defense, leveraging the unique inertness and durability of PTFE to protect the process fluid from contamination while shielding the system from corrosive media, ultimately ensuring long-term operational reliability and safety.

The Critical Function of a Perfect Seal

In high-purity and hazardous-duty industries, the connection point between two pipes is a potential point of failure. The gasket is the component that mitigates this risk.

Creating a Leak-Proof Barrier

A tri-clamp fitting works by compressing a gasket between two flanged pipe ends. The gasket deforms slightly to fill any microscopic imperfections in the metal surfaces, creating an impassable barrier that prevents leaks under pressure or vacuum.

Why a Perfect Seal is Non-Negotiable

In a pharmaceutical or food processing line, even a minor leak can lead to catastrophic consequences. It can introduce contaminants, compromise batch purity, create safety hazards for personnel, and result in costly operational downtime.

Why PTFE is the Material of Choice

The effectiveness of a gasket is defined entirely by its material properties. Polytetrafluoroethylene (PTFE) possesses a unique combination of characteristics that make it ideal for the most demanding applications.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, acids, solvents, and corrosive agents. This means the gasket will not degrade, swell, or leach unwanted substances into the process stream, which is essential for maintaining product purity and ensuring safety when handling hazardous materials.

Broad Temperature Stability

These gaskets perform reliably across a wide temperature range. Their high melting point and resistance to thermal degradation allow them to be used in systems involving extreme heat, such as steam-in-place (SIP) sterilization cycles, without losing their sealing integrity.

Exceptional Durability and Longevity

PTFE is highly resistant to wear and degradation from continuous use. This long service life means gaskets do not need to be replaced frequently, which has a direct positive impact on operational efficiency.

The Advantage of Non-Stick Properties

PTFE's famous non-stick surface minimizes the ability of process media to adhere to the gasket. This facilitates easier cleaning and reduces the risk of product buildup, a critical factor in sanitary systems where hygiene is paramount.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

The Risk of Cold Flow (Creep)

PTFE is a relatively soft material that can "creep" or deform permanently under sustained pressure, especially at higher temperatures. This can eventually lead to a loss of sealing pressure, requiring periodic re-tightening of the clamp to maintain a leak-proof connection.

Lower Elasticity Compared to Elastomers

Compared to rubber-like materials such as EPDM or silicone, PTFE is more rigid and has less "memory." It does not spring back to its original shape as effectively, making it slightly less forgiving of pipe misalignment or surface imperfections.

Making the Right Choice for Your Application

Selecting the correct gasket material is a foundational decision for ensuring system reliability.

- If your primary focus is ultimate chemical purity and compatibility: PTFE is the superior choice, especially when dealing with aggressive solvents, acids, or ultra-pure process fluids.

- If your primary focus is frequent assembly/disassembly: An elastomer-based gasket may be more suitable due to its superior elasticity and ability to rebound after compression.

- If your primary focus is long-term reliability in a harsh environment: PTFE's resistance to chemical and thermal degradation provides unmatched durability, minimizing maintenance and reducing the total cost of ownership.

Ultimately, choosing the right gasket is a critical engineering decision that directly supports the safety, efficiency, and integrity of your entire operation.

Summary Table:

| Key Property | Role in Industrial Applications |

|---|---|

| Chemical Resistance | Protects against corrosive acids, solvents, and ensures product purity. |

| Temperature Stability | Maintains integrity during high-temperature processes like SIP sterilization. |

| Non-Stick Surface | Prevents product buildup and simplifies cleaning in sanitary systems. |

| Durability | Offers long service life, reducing maintenance and total cost of ownership. |

Ensure the integrity and purity of your process with high-performance PTFE components from KINTEK.

Our precision-manufactured PTFE seals, liners, and labware are engineered to meet the demanding requirements of the semiconductor, medical, laboratory, and industrial sectors. Whether you need a standard tri-clamp gasket or a custom-fabricated solution from prototype to high-volume production, KINTEK prioritizes precision and reliability.

Contact our experts today to discuss your specific application needs and discover how our PTFE solutions can enhance your system's safety and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance