PTFE slide bearings can be installed through several standard, reliable methods. The primary techniques are bolting, tack-welding, full welding, and mortar embedment. The choice is dictated by the design of the surrounding structure, whether it's steel or concrete, and the specific bearing configuration selected for the application.

The core principle of any installation is that the method acts upon the bearing's steel backing plate, not the PTFE material itself. Success depends entirely on choosing the right bearing assembly for your intended method and meticulously protecting the sensitive PTFE sliding surface from contamination and damage during the process.

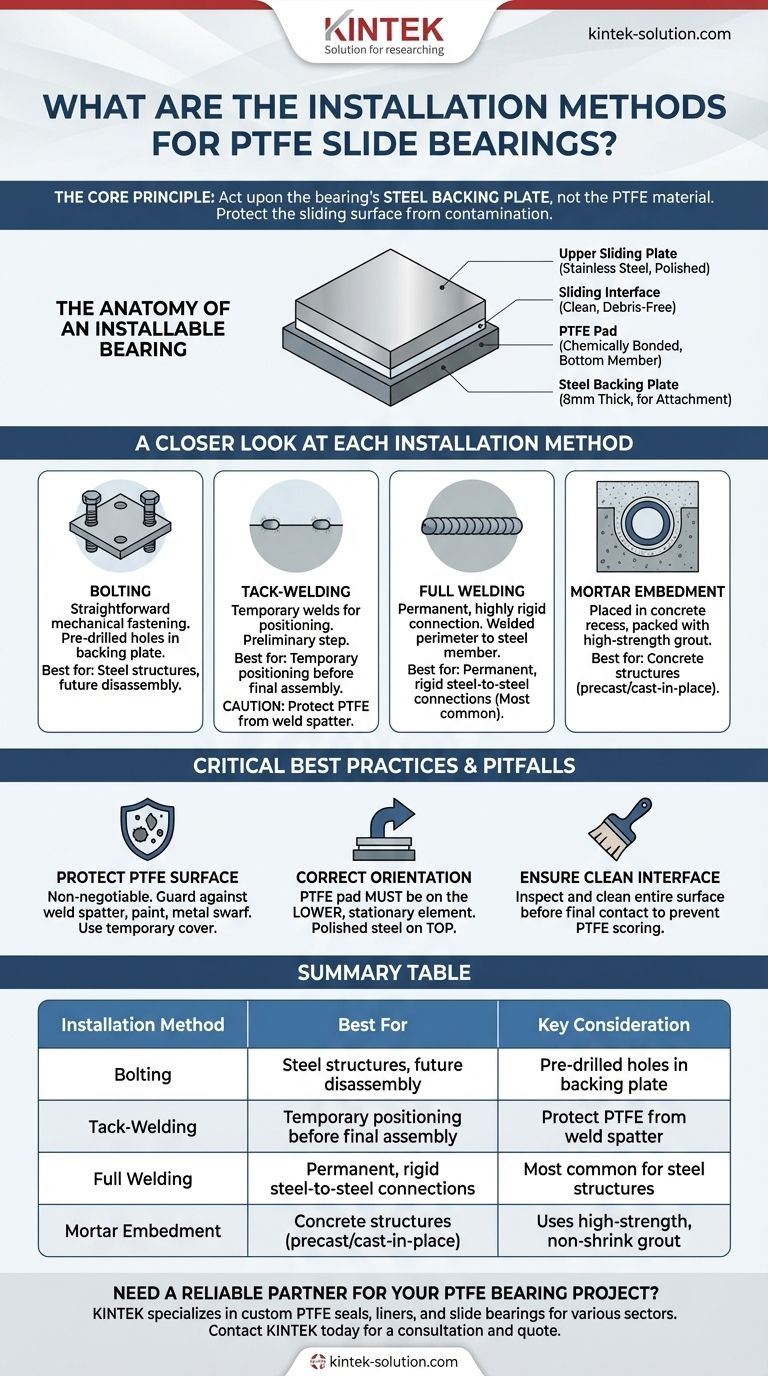

The Anatomy of an Installable Bearing

To understand the installation methods, you must first understand the bearing's construction. It's not just a piece of plastic; it's an engineered assembly designed for attachment to a larger structure.

The Backing Plate: The Foundation for Installation

A PTFE slide bearing consists of a layer of PTFE chemically bonded to a rigid backing plate, which is typically a steel plate around 8mm thick.

This steel plate is the component that is actually bolted or welded. It provides the necessary structural interface between the low-friction PTFE and the primary structure.

The Sliding Surfaces: A Two-Part System

A complete bearing assembly has two distinct parts. The lower member is the backing plate with the bonded PTFE pad facing up.

The upper member is a polished stainless steel plate that slides against the PTFE. This orientation—PTFE on the bottom, steel on the top—is critical for proper function and debris shedding.

Material Configurations Dictate Use

Different configurations exist for various environments. Standard PTFE is suitable for temperatures up to 130°C.

For higher temperatures, the design may use a thicker, 5mm PTFE layer recessed into the backing plate (up to 200°C) or even a graphite-based sliding material for extreme heat (up to 500°C).

A Closer Look at Each Installation Method

The versatility of the backing plate allows for several connection types, each suited to different structural contexts.

Bolting

Bolting is a straightforward mechanical fastening method. The backing plates are supplied with pre-drilled holes according to project specifications.

This approach is common in situations where welding is impractical or when a component may need to be disassembled in the future.

Tack-Welding

Tack-welding involves creating small, temporary welds to hold the bearing's backing plate in the correct position.

This is often a preliminary step to secure the bearing's location before the main structural members are fully assembled or welded around it.

Full Welding

For a permanent and highly rigid connection, the entire perimeter of the backing plate can be welded directly to a steel structural member.

This method creates a seamless, powerful bond, making the bearing an integral part of the structure. It is the most common method for steel-to-steel connections.

Mortar Embedment

In concrete construction, the bearing assembly is often placed in a recess or pocket formed in the concrete.

The bearing is then set to the correct elevation and fixed in place by packing high-strength, non-shrink grout or mortar around the backing plate.

Critical Best Practices and Pitfalls

Proper installation is less about the method and more about the execution. A mistake here can compromise the entire system.

Protecting the PTFE Surface is Non-Negotiable

The low-friction property of PTFE is easily destroyed by contamination. The surface must be protected at all times from on-site hazards.

Key threats include weld spatter, paint spray, and metal swarf or other construction debris. A temporary cover should be kept in place for as long as possible.

Correct Orientation Matters

Installing the bearing upside-down—with the PTFE on the upper member—is a critical error. The PTFE pad is designed to be on the lower, stationary element.

This ensures the polished stainless steel upper plate can slide freely and that the design can effectively shed debris from the sliding interface.

Ensure a Clean Interface Before Loading

Before the upper sliding plate makes final contact with the lower PTFE pad, the entire surface must be inspected and cleaned.

Any grit, dust, or debris trapped between the surfaces will score the PTFE, increase friction, and permanently degrade the bearing's performance.

Making the Right Choice for Your Project

Your choice of installation method is a direct function of your structural design and operational goals.

- If your primary focus is adaptability or avoiding on-site welding: Bolting is the most direct and potentially reversible method.

- If you are integrating into a new steel structure: Full welding provides the most robust, permanent connection to the structural members.

- If you are working with precast or cast-in-place concrete: Mortar embedment is the standard approach for seamless integration.

- If you need to secure the bearing for subsequent assembly: Tack-welding is an effective temporary fixation, but demands extreme care to protect the PTFE.

Proper installation is the final, critical step in unlocking the long-term, maintenance-free performance of a PTFE slide bearing system.

Summary Table:

| Installation Method | Best For | Key Consideration |

|---|---|---|

| Bolting | Steel structures, future disassembly | Pre-drilled holes in backing plate |

| Tack-Welding | Temporary positioning before final assembly | Protect PTFE from weld spatter |

| Full Welding | Permanent, rigid steel-to-steel connections | Most common for steel structures |

| Mortar Embedment | Concrete structures (precast/cast-in-place) | Uses high-strength, non-shrink grout |

Need a Reliable Partner for Your PTFE Bearing Project?

Choosing the right installation method is crucial, but it starts with a high-quality, precision-engineered PTFE component. KINTEK specializes in manufacturing custom PTFE seals, liners, slide bearings, and labware for the semiconductor, medical, laboratory, and industrial sectors. We ensure your components are designed for a seamless installation and long-term, maintenance-free performance.

Let us provide the precision and expertise your project demands, from prototypes to high-volume orders.

Contact KINTEK today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications