To enhance its sealing properties, Polytetrafluoroethylene (PTFE) is modified by incorporating fillers and additives. These materials are compounded directly into the virgin PTFE to create a composite that overcomes the inherent mechanical limitations of the pure polymer, such as its tendency to deform under pressure. The result is a material with significantly improved dimensional stability, wear resistance, and overall durability in demanding sealing applications.

While pure PTFE offers elite chemical and thermal resistance, it often lacks the mechanical robustness required for high-performance seals. Modifying it with specific fillers fundamentally transforms it from a soft polymer into a resilient composite engineered to resist wear and deformation.

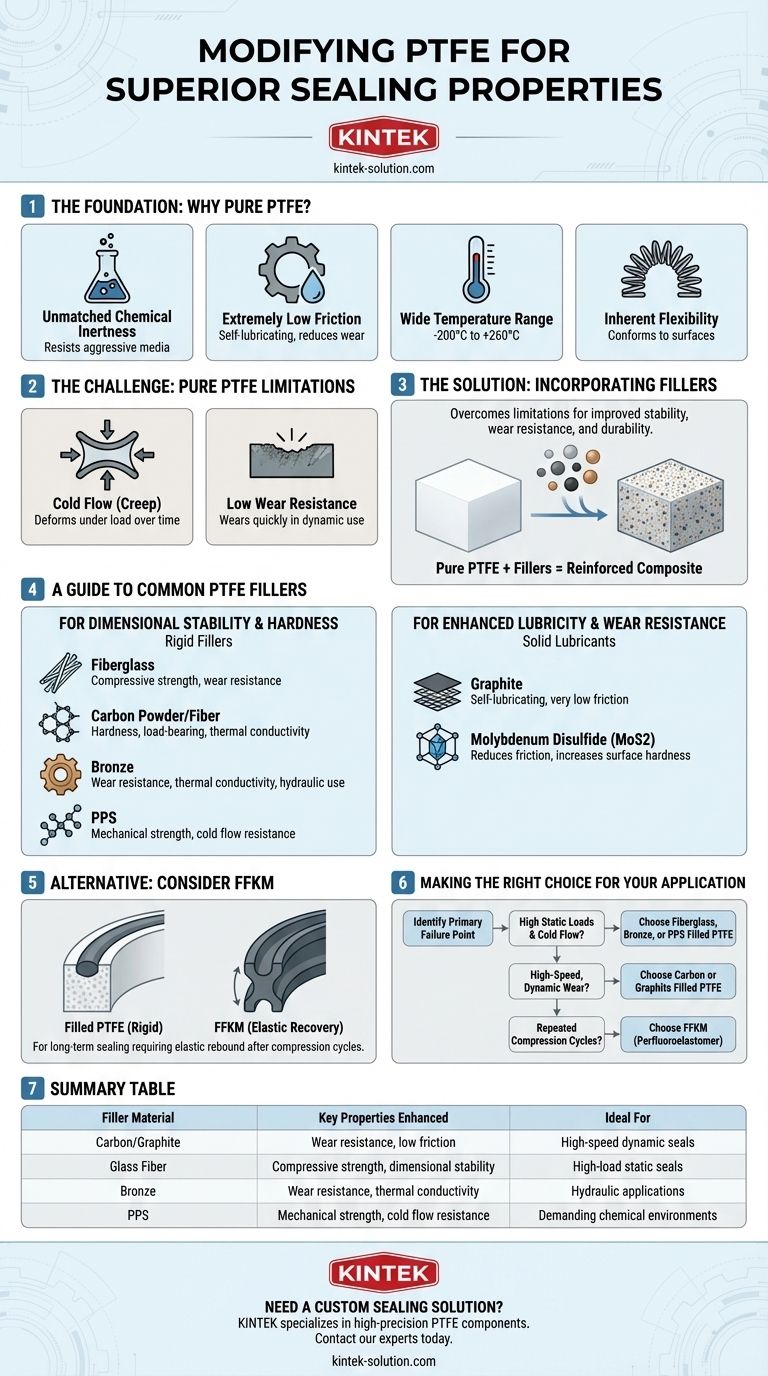

The Foundation: Why PTFE is a Premier Sealing Material

Before exploring modifications, it's crucial to understand why pure PTFE is such a common choice for seals. Its inherent properties provide an exceptional starting point for a wide range of applications.

Unmatched Chemical Inertness

PTFE is virtually immune to chemical attack from strong acids, alkalis, and other corrosive media. This ensures the seal maintains its integrity and prevents leaks even in the most aggressive chemical environments.

Extremely Low Friction

With one of the lowest coefficients of friction of any solid, PTFE reduces wear on rotating shafts and other moving parts. Its self-lubricating properties are ideal for non-lubricated systems, improving efficiency and extending the life of the entire assembly.

Wide Temperature Range

PTFE performs reliably across an exceptionally broad temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F). This thermal stability allows it to be used in applications ranging from cryogenics to high-heat industrial processes.

Inherent Flexibility

The material's flexibility allows it to conform perfectly to sealing surfaces and shafts. This adaptability ensures a tight, consistent seal even in dynamic applications with rotating or oscillating components.

Overcoming PTFE's Inherent Limitations

Despite its advantages, pure PTFE has two key weaknesses that can lead to seal failure in demanding conditions: low wear resistance and a phenomenon known as "cold flow."

The Challenge of Cold Flow

Cold flow, or creep, is the tendency of pure PTFE to slowly deform or "flow" away from a concentrated load over time, even at room temperature. In a seal, this can cause a loss of sealing pressure, leading to leaks and eventual failure.

The Need for Enhanced Wear Resistance

In dynamic seals or environments with abrasive media, pure PTFE can wear down too quickly. Improving its hardness and durability is essential for extending the operational life of the seal and minimizing equipment downtime.

A Guide to Common PTFE Fillers

Adding fillers is the primary strategy for mitigating PTFE's weaknesses. Each filler imparts specific properties, allowing the material to be tailored to the application.

For Dimensional Stability and Hardness

To combat cold flow and increase hardness, rigid fillers are added.

- Fiberglass: Improves compressive strength and wear resistance.

- Carbon Powder/Fiber: Significantly increases hardness, load-bearing capacity, and thermal conductivity while maintaining low friction.

- Bronze: Provides excellent wear resistance and high thermal conductivity, making it ideal for hydraulic applications.

- PPS (Polyphenylene Sulfide): Offers excellent mechanical strength and resistance to cold flow.

For Enhanced Lubricity and Wear Resistance

For high-speed, non-lubricated applications, solid lubricants are compounded into the PTFE.

- Graphite: Creates a self-lubricating composite with very low friction, perfect for components like compressor piston rings.

- Molybdenum Disulfide (MoS2): Reduces friction and increases surface hardness, especially when combined with other fillers.

Understanding the Trade-offs and Alternatives

While fillers dramatically improve PTFE's mechanical properties, choosing the right material requires a clear understanding of the complete system.

Choosing the Right Filler

The key is to match the filler to the primary challenge. Adding bronze to a seal in a highly corrosive chemical application may not be suitable, whereas a carbon-filled seal would be. The selection process is a balancing act between improving mechanical strength and maintaining the necessary chemical and thermal resistance.

When to Consider an Alternative: FFKM

In some cases, a different material may be a better solution. Perfluoroelastomer (FFKM) offers chemical and thermal resistance on par with PTFE but adds the elastic recovery of a rubber. This makes FFKM a superior choice for long-term sealing in applications that require the seal to rebound and maintain its force after compression cycles.

Making the Right Choice for Your Application

Selecting the optimal material requires identifying the most likely point of failure for your seal.

- If your primary focus is preventing deformation under high static loads: Choose a PTFE compounded with fiberglass, bronze, or PPS to maximize resistance to cold flow.

- If your primary focus is durability in a high-speed, dynamic seal: Select a carbon or graphite-filled PTFE for its superior wear resistance and self-lubricating properties.

- If your primary focus is maintaining a seal after repeated compression cycles: An elastomeric alternative like FFKM may provide better long-term reliability than any filled PTFE.

Ultimately, modifying PTFE is about engineering a solution that leverages its exceptional chemical and thermal properties while reinforcing its mechanical weaknesses.

Summary Table:

| Filler Material | Key Properties Enhanced | Ideal For |

|---|---|---|

| Carbon/Graphite | Wear resistance, low friction | High-speed dynamic seals |

| Glass Fiber | Compressive strength, dimensional stability | High-load static seals |

| Bronze | Wear resistance, thermal conductivity | Hydraulic applications |

| PPS | Mechanical strength, cold flow resistance | Demanding chemical environments |

Need a custom sealing solution that combines PTFE's chemical resistance with superior mechanical performance? KINTEK specializes in manufacturing high-precision PTFE components, including seals, liners, and custom labware. We use advanced compounding techniques to incorporate fillers like carbon, glass, and bronze, tailoring the material to your exact application requirements—whether you're in the semiconductor, medical, laboratory, or industrial sector. From prototypes to high-volume orders, we ensure your seals deliver unmatched durability and reliability. Contact our experts today to discuss your project and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What factors should be considered when choosing a filler for PTFE? Enhance Performance for Your Application

- In which applications are anti-static PTFE bellows used? Essential for Static-Sensitive Industries

- How are Teflon-encapsulated O-Rings utilized in heavy equipment and hydraulics? Achieve Superior Sealing and Reduce Downtime

- How do PTFE spring-energized seals perform in defense and nuclear environments? Engineered for Extreme Reliability.

- What is creep in PTFE gasket sheets and how can it be mitigated? Prevent Seal Failure and Leaks

- How does PTFE's porous structure support medical applications? Unlocking Biocompatible Scaffolds and Filtration

- What types of PTFE components are used in the gas and oil industry? Enhance Reliability in Extreme Conditions

- What materials are used to manufacture PTFE bars? A Guide to Virgin & Filled PTFE