At its core, expanded Polytetrafluoroethylene (ePTFE) is a highly versatile material that retains the remarkable chemical and thermal resistance of standard PTFE while adding unique physical properties through its microporous structure. This structure, a web of interconnected fibers and pores, gives ePTFE enhanced flexibility, porosity, and biocompatibility, making it suitable for a vast range of demanding applications where solid PTFE would fail.

The crucial difference is structural: ePTFE transforms the solid, dense nature of standard PTFE into a flexible, microporous material. This change unlocks new capabilities in sealing, medical implants, and filtration while preserving PTFE’s signature chemical inertness and temperature resistance.

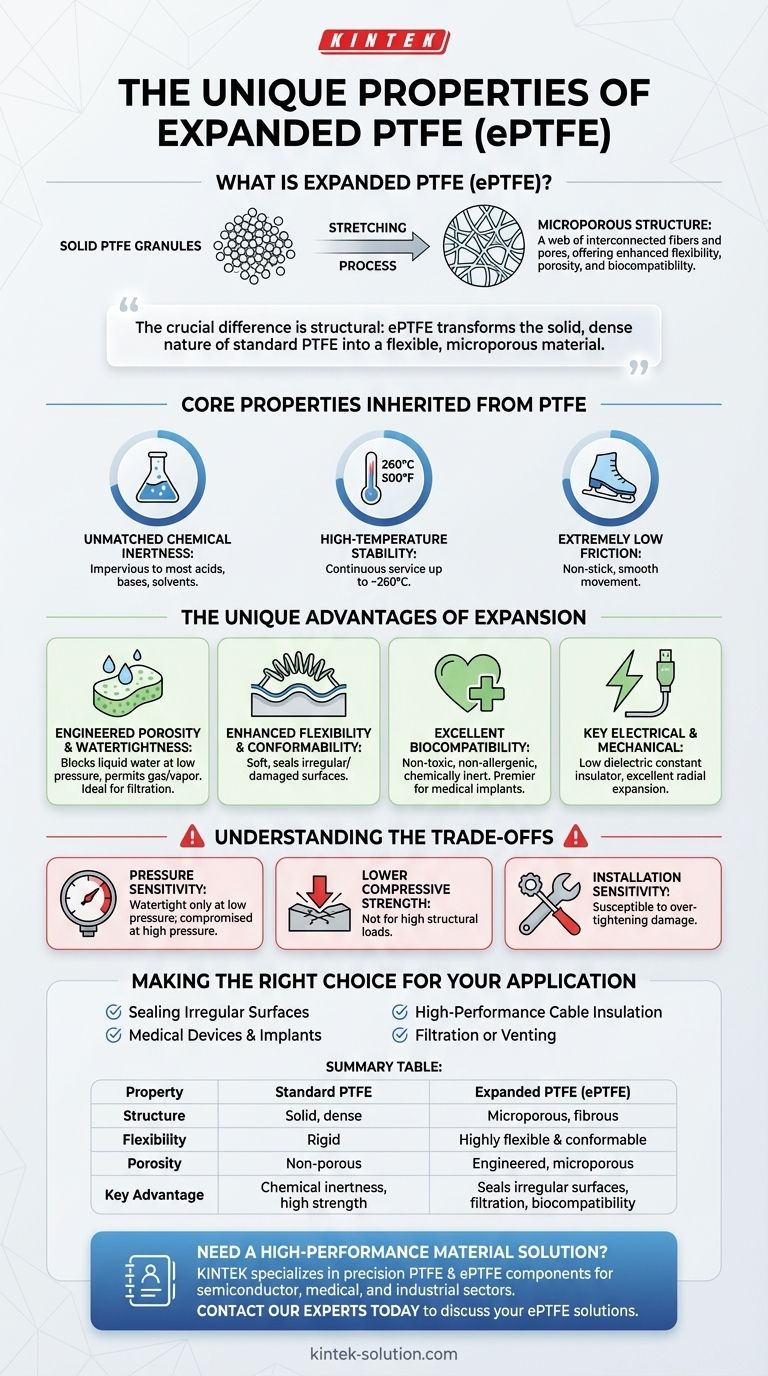

From Solid to Microporous: The ePTFE Difference

The unique properties of ePTFE are a direct result of its manufacturing process. It starts as standard PTFE but undergoes a mechanical expansion or stretching process.

The Expansion Process

This process creates a distinct microstructure. It pulls the PTFE polymer into a network of strong, thin fibers interconnected by solid nodes, forming countless microscopic pores throughout the material.

The Resulting Structure

This unique "mesh structure" is the source of all of ePTFE's advanced properties. The size of the pores and the density of the material can be precisely controlled, allowing it to be engineered for specific performance characteristics.

Core Properties Inherited from PTFE

Before exploring its unique advantages, it's essential to recognize that ePTFE is built on the exceptionally robust foundation of its parent material, PTFE.

Unmatched Chemical Inertness

Like standard PTFE, ePTFE is virtually impervious to chemical attack. It shows excellent resistance to most acids, bases, solvents, and other aggressive organic and mineral chemicals.

High-Temperature Stability

ePTFE maintains its performance and integrity in extreme temperature environments, capable of withstanding continuous service temperatures up to approximately 260°C (500°F).

Extremely Low Friction

It retains the famously low coefficient of friction of PTFE, often compared to wet ice on wet ice. This "non-stick" property is critical for applications requiring smooth movement or easy removal.

The Unique Advantages of Expansion

The microporous structure created during expansion gives ePTFE properties that solid PTFE cannot offer.

Engineered Porosity and Watertightness

The microscopic pores make ePTFE an ideal material for filtration. Despite this porosity, it remains watertight at low pressures, as the pores are too small for liquid water to pass through easily. This allows it to block liquids while permitting gases or water vapor to pass.

Enhanced Flexibility and Conformability

Unlike rigid, solid PTFE, ePTFE is soft, flexible, and highly conformable. This allows it to create an excellent seal on irregular, damaged, or sensitive surfaces like plastic or glass flanges, where a rigid gasket would fail.

Excellent Biocompatibility

ePTFE is non-toxic, non-allergenic, and chemically inert within the body. This outstanding biocompatibility makes it a premier material for medical devices, including surgical sutures, vascular grafts, and implants.

Key Electrical and Mechanical Properties

The material possesses a low dielectric constant, making it an excellent insulator for high-performance wiring and cables. Its structure also provides excellent radial expansion, allowing it to fit snugly in various applications.

Understanding the Trade-offs

While ePTFE is an exceptional material, its unique structure comes with practical limitations that are important to understand.

Pressure Sensitivity

The "watertight" property is explicitly noted to be effective at low pressure. Under high compressive loads or high fluid pressures, the microporous structure can be compromised, potentially leading to leaks.

Lower Compressive Strength

Because it is porous and not a solid block, ePTFE does not have the same compressive strength or rigidity as standard PTFE. It is not suitable for applications that require high structural or load-bearing capabilities.

Installation Sensitivity

Its softness makes installation easy, but it also makes it susceptible to damage. Over-tightening an ePTFE gasket or seal can crush the microporous structure, destroying its sealing ability. Proper installation torque is critical.

Making the Right Choice for Your Application

Selecting ePTFE is about leveraging its unique combination of properties for a specific technical challenge.

- If your primary focus is sealing irregular or sensitive surfaces: ePTFE's flexibility makes it the ideal choice for creating a tight seal on plastic flanges, glass-lined vessels, or damaged metal faces.

- If your primary focus is medical devices or implants: Its proven biocompatibility and chemical inertness are critical for ensuring patient safety and device longevity.

- If your primary focus is high-performance cable insulation: The low dielectric constant and high-temperature resistance provide superior electrical performance.

- If your primary focus is filtration or venting: The controlled, microporous structure allows you to create a barrier that is both waterproof and breathable.

Expanded PTFE provides a unique solution where the properties of a high-performance polymer and a flexible, porous material are required simultaneously.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Structure | Solid, dense | Microporous, fibrous network |

| Flexibility | Rigid | Highly flexible and conformable |

| Porosity | Non-porous | Engineered, microporous |

| Key Advantage | Chemical inertness, high compressive strength | Seals irregular surfaces, filtration, biocompatibility |

Need a high-performance material solution?

KINTEK specializes in manufacturing precision PTFE and ePTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a component perfectly engineered for your application's unique demands, whether you require superior chemical resistance, precise porosity, or excellent biocompatibility.

Contact our experts today to discuss how our ePTFE solutions can solve your technical challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the radiation resistance of PTFE and mPTFE? Key Insights for Semiconductor & Medical Applications

- What are some applications of PTFE seals? Discover Their Critical Role in Demanding Industries

- What are the structural differences between PTFE oil seals and rubber oil seals? A Guide to Lip Design & Performance

- Why are PTFE envelope gaskets suitable for food processing and pharmaceutical applications? Ensure Product Purity and Compliance

- What situations typically require the use of a spring with PTFE seal elements? Overcome PTFE's Limitations for Reliable Sealing

- What are some real-world applications of PTFE coatings? Solve Friction, Corrosion & Contamination

- What are the differences between virgin PTFE and mechanical PTFE? Select the Right Grade for Your Application

- What role do ceramic fillers play in PTFE laminates? Enhance Signal Integrity & Thermal Performance