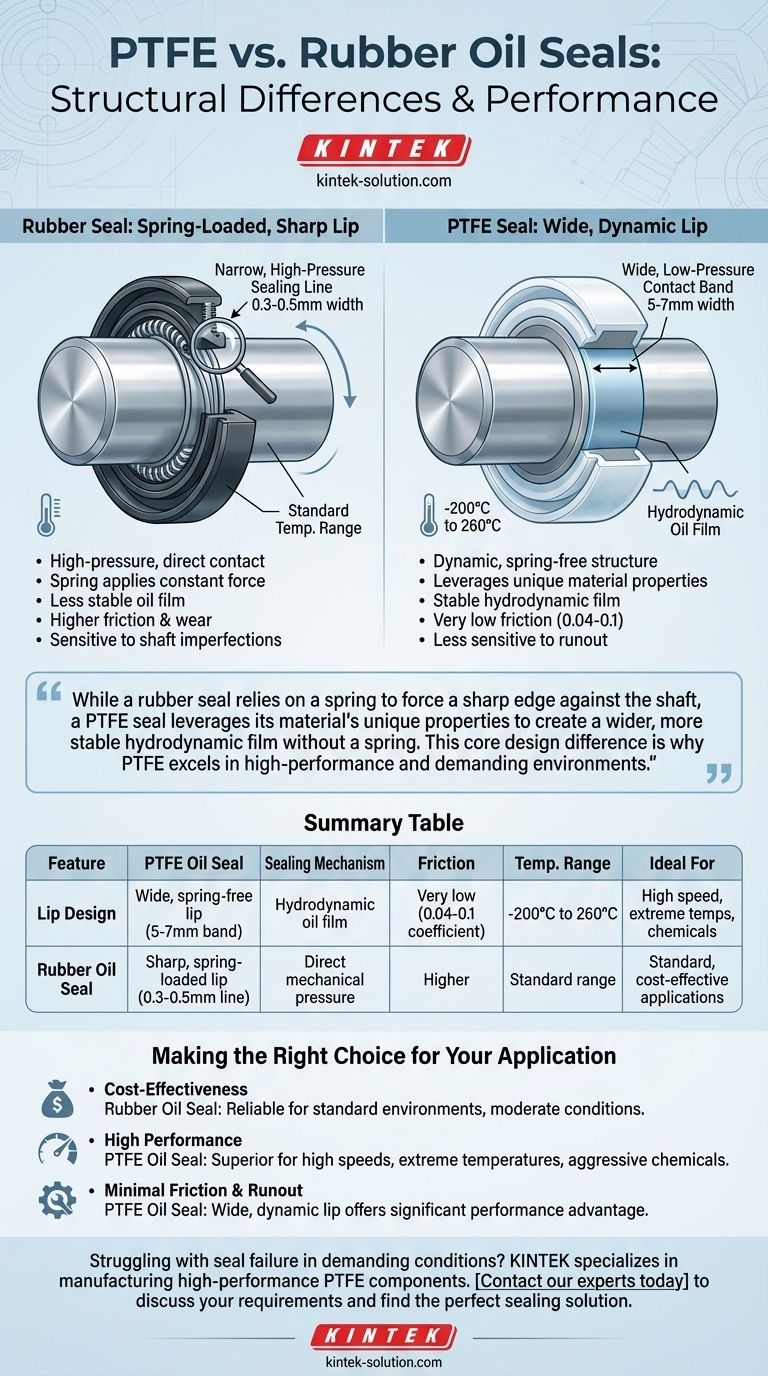

The fundamental structural difference between PTFE and rubber oil seals lies entirely in their lip design and sealing mechanism. A traditional rubber seal uses a sharp, spring-loaded lip to create a narrow, high-pressure sealing line, whereas a PTFE seal employs a wide, spring-free lip that creates a broader, lower-pressure contact band. This distinction in form is a direct result of the materials' different properties and dictates their performance in an application.

While a rubber seal relies on a spring to force a sharp edge against the shaft, a PTFE seal leverages its material's unique properties to create a wider, more stable hydrodynamic film without a spring. This core design difference is why PTFE excels in high-performance and demanding environments.

Deconstructing the Seal Lip: The Core Structural Difference

The most significant distinction between these two seal types is the shape and function of the sealing lip, which is the part of the seal that makes contact with the rotating shaft.

The Rubber Seal: A Spring-Loaded, Sharp Lip

A conventional rubber oil seal is designed with a very thin, flexible sealing lip.

This lip is energized by a garter spring, which applies a constant radial force, pressing the sharp edge firmly against the shaft.

The actual contact surface is extremely narrow, typically only 0.3mm to 0.5mm wide. This design focuses all the sealing force onto a tiny line of contact.

The PTFE Seal: A Wide, Dynamic Lip

In contrast, a PTFE oil seal features a much wider, more robust lip structure and typically operates without a spring.

This design creates a broad contact band on the shaft, measuring between 5mm and 7mm wide.

This "wide lip" approach is considered a dynamic structure, engineered to work with the system's lubricant to form a seal, rather than relying purely on mechanical pressure.

Why This Structural Difference Matters

The choice between a narrow, spring-loaded lip and a wide, spring-free lip has direct consequences for performance, durability, and operational range. These structural differences are not arbitrary; they are intentional designs meant to capitalize on the strengths of each material.

Creating a Stable Oil Film

The wide lip of a PTFE seal is specifically designed to maintain a sufficient hydrodynamic oil film between the seal and the shaft. This layer of lubricant reduces friction and wear.

The narrow lip of a rubber seal relies more heavily on direct pressure, which can lead to higher friction and a less stable lubricating film, especially at high speeds.

Handling Shaft Imperfections

The broader contact area of the PTFE seal makes it inherently less sensitive to shaft eccentricity or "runout." It can maintain a consistent seal even if the shaft's rotation is not perfectly centered.

The sharp, high-pressure line of a rubber seal can be more easily disrupted by shaft imperfections, potentially leading to leaks over time.

The Role of Friction

PTFE has an extremely low coefficient of friction (0.04 to 0.1). This property is what makes the wide-lip design possible. A wide rubber lip would generate excessive heat and wear, leading to rapid failure.

The low-friction nature of the PTFE structure allows it to handle much higher rotational speeds and pressures without overheating or degrading.

Understanding the Trade-offs

While the PTFE seal's structure offers clear advantages in demanding situations, the conventional rubber seal remains a viable and effective solution for many common applications.

The Performance Advantage of PTFE

PTFE seals are built for harsh environments. Their structure and material properties give them superior resistance to a wider temperature range (-200°C to 260°C), aggressive chemicals, and aging.

This results in a significantly longer service life, often lasting 10,000 to 50,000 hours in applications where a rubber seal would fail quickly.

The Cost-Effectiveness of Rubber

For standard operating conditions without extreme temperatures, high pressures, or aggressive media, rubber oil seals perform reliably.

They are a proven, cost-effective solution and remain the standard choice for a vast number of common industrial and automotive applications.

Making the Right Choice for Your Application

The choice is not about which seal is "better" in a vacuum, but which is correctly suited for the operational demands.

- If your primary focus is cost-effectiveness in a standard environment: A traditional rubber oil seal is a reliable and economical choice for moderate temperatures, speeds, and pressures.

- If your application involves high speeds, extreme temperatures, or aggressive chemicals: The superior structure and material properties of a PTFE oil seal are necessary for reliability and long service life.

- If you need to minimize friction and handle potential shaft runout: The wide, dynamic lip of a PTFE seal offers a significant and more stable performance advantage.

Ultimately, selecting the correct seal requires matching its unique structural and material advantages to the specific demands of your operating environment.

Summary Table:

| Feature | PTFE Oil Seal | Rubber Oil Seal |

|---|---|---|

| Lip Design | Wide, spring-free lip (5-7mm band) | Sharp, spring-loaded lip (0.3-0.5mm line) |

| Sealing Mechanism | Hydrodynamic oil film | Direct mechanical pressure |

| Friction | Very low (0.04-0.1 coefficient) | Higher |

| Temp. Range | -200°C to 260°C | Standard range |

| Ideal For | High speed, extreme temps, chemicals | Standard, cost-effective applications |

Struggling with seal failure in demanding conditions? The right structural design is critical for performance. KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. We offer precision production and custom fabrication from prototypes to high-volume orders to ensure your application runs reliably.

Contact our experts today to discuss your specific requirements and find the perfect sealing solution.

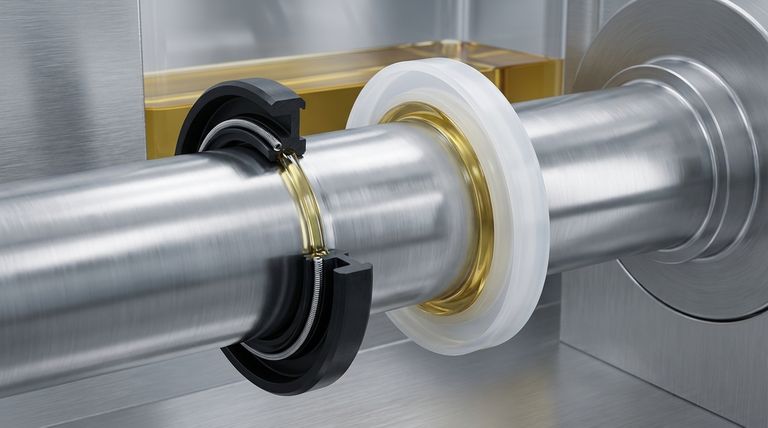

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications