In short, Polytetrafluoroethylene (PTFE) seals are used in a vast array of demanding applications across nearly every major industry. You will find them in everything from aircraft engines and automotive brake systems to chemical processing pumps, food manufacturing equipment, and medical devices. Their widespread use stems from a unique combination of properties that allow them to perform where many other materials would fail.

The core reason for PTFE's versatility is its ability to solve multiple engineering challenges at once. It simultaneously offers near-universal chemical inertness, an extremely wide operating temperature range, and one of the lowest coefficients of friction of any solid material.

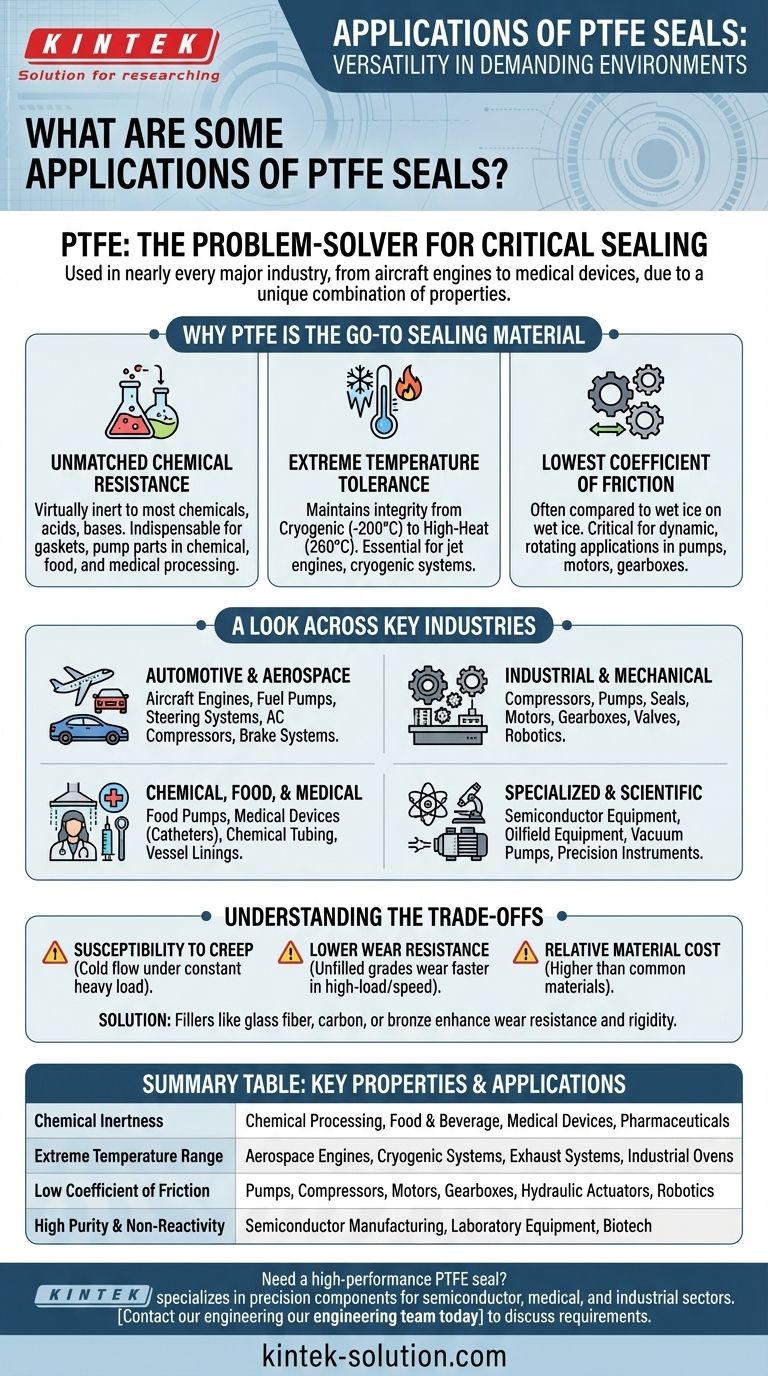

Why PTFE Is the Go-To Sealing Material

PTFE's value isn't just in one single attribute, but in the powerful combination of its inherent characteristics. This unique profile makes it a problem-solver in critical sealing applications.

Unmatched Chemical Resistance

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases.

This property makes it indispensable in chemical processing for gaskets, valve components, and pump parts. It is also why it's a first choice in food, beverage, and medical applications, where purity and non-reactivity are paramount.

Extreme Temperature Tolerance

PTFE seals maintain their integrity and performance across an exceptionally broad temperature spectrum, from cryogenic lows (-200°C) to high-heat environments (up to 260°C).

This makes them suitable for punishing applications like jet engines and exhaust gas systems, as well as specialized cryogenic systems used in scientific and industrial fields.

The Lowest Coefficient of Friction

Often compared to wet ice on wet ice, PTFE has an extremely low coefficient of friction. This means components can move against it with minimal resistance or wear.

This is critical for dynamic, rotating applications. It's the reason PTFE seals are essential in motors, gearboxes, pumps, compressors, and hydraulic actuators—anywhere a seal must function against a moving shaft.

A Look Across Key Industries

While the properties explain why PTFE is chosen, looking at industry-specific examples shows how it is deployed.

In Automotive and Aerospace

These industries demand absolute reliability under extreme pressure and temperature fluctuations.

PTFE seals are used in critical systems such as aircraft engines, fuel injection pumps, steering systems, air conditioning compressors, and automotive brake systems.

In Industrial and Mechanical Engineering

This is the broadest category, where PTFE seals are used to ensure the efficiency and longevity of machinery.

Common applications include compressors, pumps, mechanical seals, motors, gearboxes, valves, robotics, and mixers.

In Chemical, Food, and Medical Processing

Purity, hygiene, and resistance to corrosion are the primary drivers in these fields.

PTFE is used for seals in food processing pumps, medical devices like catheters, chemical-resistant tubing, and as vessel linings to prevent contamination and corrosion.

In Specialized and Scientific Equipment

In highly controlled or harsh environments, material performance is non-negotiable.

You will find PTFE in semiconductor equipment, oilfield equipment, vacuum pumps, and various other forms of precision scientific instruments.

Understanding the Trade-offs

No material is perfect, and being an effective advisor means acknowledging limitations. While powerful, PTFE has characteristics that require consideration.

Susceptibility to Creep

In its pure, unfilled form, PTFE can be prone to "creep" or cold flow. This means it can slowly deform over time if placed under a constant, heavy load.

Lower Wear Resistance (When Unfilled)

For high-load, high-speed dynamic applications, pure PTFE can wear more quickly than other engineered polymers.

To counteract this, PTFE is often blended with fillers like glass fiber, carbon, or bronze. These "bearing grades" significantly enhance wear resistance and rigidity.

Relative Material Cost

As a high-performance polymer, PTFE is generally more expensive than common sealing materials like nitrile or neoprene. Its selection is a deliberate choice for applications where lesser materials would certainly fail.

Making the Right Choice for Your Application

Ultimately, the decision to use a PTFE seal is driven by the specific demands of the environment.

- If your primary focus is handling aggressive chemicals or ensuring purity: PTFE is almost always the correct choice due to its near-universal inertness.

- If your primary focus is a high-speed rotating or dynamic system: A filled PTFE grade should be your starting point to ensure durability and long wear life.

- If your primary focus is performance in extreme temperatures (high or cryogenic): PTFE's exceptionally wide operating range makes it a leading candidate.

PTFE's unique properties make it one of the most versatile and reliable high-performance sealing materials available to engineers today.

Summary Table:

| Key PTFE Seal Property | Primary Industry Applications |

|---|---|

| Chemical Inertness | Chemical Processing, Food & Beverage, Medical Devices, Pharmaceuticals |

| Extreme Temperature Range | Aerospace Engines, Cryogenic Systems, Exhaust Systems, Industrial Ovens |

| Low Coefficient of Friction | Pumps, Compressors, Motors, Gearboxes, Hydraulic Actuators, Robotics |

| High Purity & Non-Reactivity | Semiconductor Manufacturing, Laboratory Equipment, Biotech |

Need a high-performance PTFE seal for your demanding application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard solution or a custom-fabricated part from prototype to high-volume production, our expertise ensures a seal that delivers unmatched chemical resistance, thermal stability, and low friction.

Contact our engineering team today to discuss your specific requirements and get a solution that guarantees reliability and performance.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- How do PTFE seals perform under pressurized conditions? Achieving Reliable Sealing in Demanding Environments

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are PTFE seals and why are they considered a reliable solution for extreme environments? Engineered for Harsh Conditions