At its core, the difference between virgin and mechanical Polytetrafluoroethylene (PTFE) comes down to purity and origin. Virgin PTFE is manufactured from 100% pure, new resin, making it the highest-grade material. Mechanical grade PTFE, in contrast, is produced using reprocessed or recycled PTFE resin, creating a cost-effective alternative with slightly different properties.

The primary decision driver is the application's sensitivity. Choose Virgin PTFE for applications demanding absolute purity, FDA compliance, and maximum performance consistency. Choose Mechanical PTFE for cost-sensitive, non-critical mechanical parts where slight variations in physical properties are acceptable.

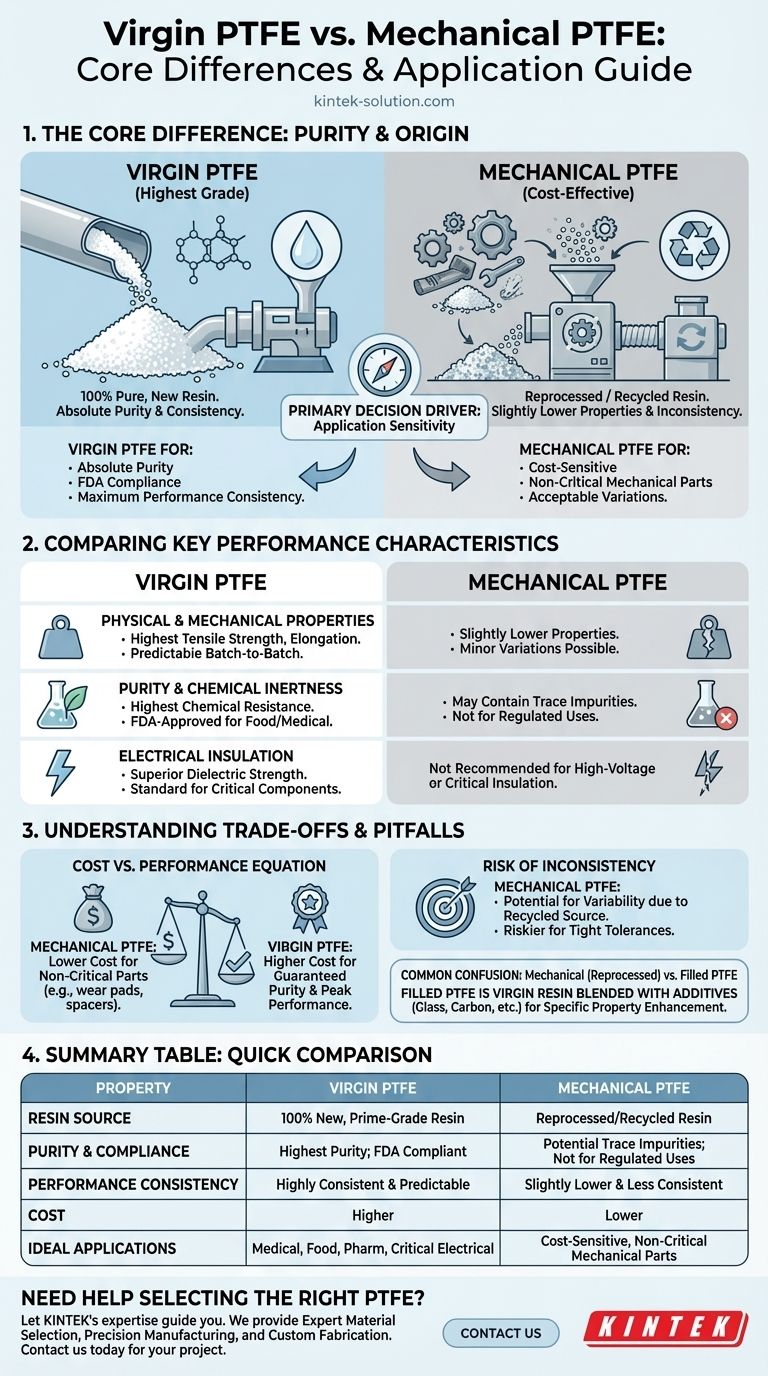

The Fundamental Difference: Resin Composition

The distinction between these two materials begins and ends with the source of the raw PTFE resin used in their production.

Virgin PTFE: The Purest Form

Virgin PTFE is made exclusively from new, prime-grade resin granules. No recycled or reprocessed material is included.

This absolute purity ensures the most consistent chemical, mechanical, and electrical properties. It is the only grade of PTFE that is FDA-approved for contact with food, pharmaceuticals, and medical devices.

Mechanical PTFE: The Reprocessed Alternative

Mechanical grade PTFE is produced using reground or reprocessed material from other manufacturing runs.

This approach significantly reduces material cost. While it retains the key characteristics of PTFE—such as low friction and high-temperature resistance—the inclusion of recycled content means its properties are slightly lower and less consistent than its virgin counterpart.

Comparing Key Performance Characteristics

While both materials share the fundamental benefits of PTFE, their specific performance profiles are tailored to different use cases.

Physical and Mechanical Properties

Virgin PTFE exhibits the highest tensile strength, elongation, and overall physical performance. Its properties are highly predictable from batch to batch.

Mechanical PTFE has slightly lower physical properties and may have minor variations. However, it still offers excellent performance for many industrial uses and is perfectly suitable for less demanding mechanical parts.

Purity and Chemical Inertness

As the purest form, virgin PTFE offers the highest level of chemical resistance and is considered chemically inert for most applications. This is critical in semiconductor, pharmaceutical, and food processing industries.

Mechanical grade PTFE may contain trace impurities from its recycling process, making it unsuitable for applications where absolute purity is a regulatory or performance requirement.

Electrical Insulation

The purity of virgin PTFE makes it an exceptional electrical insulator with superior dielectric strength. It is the standard choice for critical electrical and electronic components.

Mechanical PTFE is generally not recommended for high-voltage or critical electrical insulation applications due to potential impurities that can compromise its dielectric properties.

Understanding the Trade-offs and Pitfalls

Selecting the wrong grade of PTFE can lead to unnecessary costs or component failure. Understanding the core trade-offs is essential.

The Cost vs. Performance Equation

The most significant advantage of mechanical PTFE is its lower cost. For non-critical applications like wear pads, spacers, or general-purpose seals, it provides sufficient performance at a better price point.

Virgin PTFE commands a higher price, which is justified by its guaranteed purity, regulatory compliance, and peak performance for mission-critical components.

The Risk of Inconsistency

The primary drawback of mechanical PTFE is the potential for inconsistency. Because it is made from recycled material, its exact composition and physical properties can vary more than virgin PTFE. This makes it a riskier choice for applications with tight performance tolerances.

Common Point of Confusion: Mechanical vs. Filled PTFE

It is critical to distinguish mechanical (reprocessed) PTFE from filled PTFE.

Filled PTFE is typically made from virgin PTFE resin that has been blended with additives like glass, carbon, or bronze. These fillers dramatically enhance specific properties like wear resistance or compressive strength, but it is a fundamentally different material from reprocessed mechanical grade.

Making the Right Choice for Your Application

Your final decision should be guided entirely by the demands of your specific project.

- If your primary focus is food, pharmaceutical, or medical contact: You must use Virgin PTFE for its guaranteed purity and FDA compliance.

- If your primary focus is high-performance electrical insulation: Choose Virgin PTFE for its superior and consistent dielectric strength.

- If your primary focus is cost-sensitive mechanical components: Mechanical PTFE is an excellent choice for non-critical parts like washers, gaskets, or wear pads.

- If your primary focus is maximum wear resistance or load-bearing capacity: You should evaluate a Filled PTFE grade, which is specifically engineered for these demanding applications.

Ultimately, understanding the distinction between purity and reprocessing allows you to select the precise material your application requires without over-engineering or compromising on safety.

Summary Table:

| Property | Virgin PTFE | Mechanical PTFE |

|---|---|---|

| Resin Source | 100% new, prime-grade resin | Reprocessed/recycled resin |

| Purity & Compliance | Highest purity; FDA compliant | Potential trace impurities; not for regulated uses |

| Performance Consistency | Highly consistent and predictable | Slightly lower and less consistent |

| Cost | Higher | Lower |

| Ideal Applications | Medical, food, pharmaceutical, critical electrical | Cost-sensitive, non-critical mechanical parts |

Need Help Selecting the Right PTFE Material?

Choosing between virgin, mechanical, or filled PTFE is critical to your project's success, performance, and budget. Let KINTEK's expertise guide you.

We provide:

- Expert Material Selection: Our specialists will help you choose the perfect PTFE grade—whether virgin for absolute purity or mechanical for cost-efficiency—based on your specific application requirements.

- Precision Manufacturing: From prototypes to high-volume orders, we manufacture high-quality PTFE components (seals, liners, labware, and more) with the precision demanded by the semiconductor, medical, laboratory, and industrial sectors.

- Custom Fabrication: We tailor our fabrication process to meet your exact specifications, ensuring optimal performance for your specialized needs.

Contact us today to discuss your project and receive a quote. Let's ensure you get the right material and a perfectly manufactured component.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech