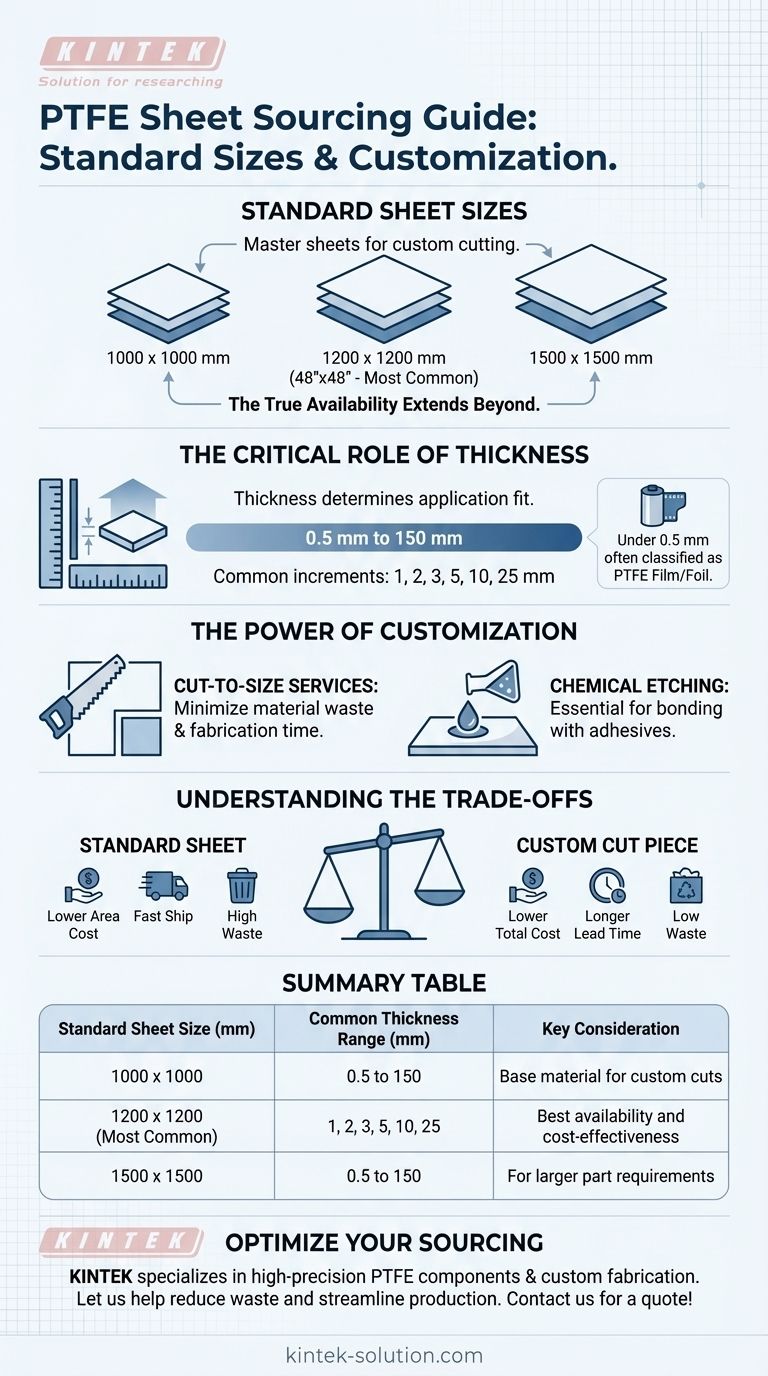

The standard sheet sizes for PTFE are typically 1000x1000 mm, 1200x1200 mm (often expressed as 48"x48"), and 1500x1500 mm. These dimensions represent the large-format sheets produced by manufacturers, from which nearly any smaller size can be cut.

While common square dimensions exist, the critical factor in selecting a PTFE sheet is not just its length and width, but the interplay between its thickness and your application's requirements. True material specification goes beyond standard sizes to include custom cuts and specialized treatments.

Understanding "Standard" vs. "Available"

The term "standard size" refers to the master sheets that are most cost-effective to produce and keep in stock. However, the true availability for your project extends far beyond these few dimensions.

The Most Common Sheet Dimensions

The most frequently stocked PTFE sheet size is 1200x1200 mm, or its imperial equivalent, 48"x48". You will also commonly find 1000x1000 mm and 1500x1500 mm sheets available from major suppliers. These serve as the raw material for smaller, custom-cut pieces.

The Critical Role of Thickness

Thickness is a more defining characteristic than sheet dimensions for most applications. PTFE sheets are available in a wide range of standard thicknesses, typically from 0.5 mm up to 150 mm.

Common increments include 1 mm, 2 mm, 3 mm, 5 mm, 10 mm, and 25 mm.

It's important to note that very thin PTFE (typically under 0.5 mm or 1 mm) is often categorized and manufactured as PTFE film or foil, which may have different properties and availability than thicker "sheets."

Beyond Sheets: Other PTFE Forms

While sheets are versatile, remember that PTFE is also readily available in other stock forms. These include rods, tubes, and tapes, which may be a more efficient starting point depending on your final part geometry.

The Power of Customization

Relying solely on standard sheet sizes is rare in practice. Most projects require specific dimensions, which suppliers are fully equipped to provide.

Cut-to-Size Services

Virtually all suppliers offer services to cut large, standard sheets into your exact required dimensions. This is fundamental to minimizing material waste and reducing your own fabrication time and cost.

Surface Treatments for Bonding

PTFE is famous for its low-friction, non-stick surface. This makes it extremely difficult to bond using conventional adhesives.

For applications requiring adhesion, you must specify a sheet that has been chemically etched on one side. This process alters the surface chemistry of the PTFE, making it receptive to bonding agents.

Understanding the Trade-offs

Choosing between a standard size and a custom-cut piece involves balancing cost, lead time, and material efficiency.

Cost: Standard vs. Custom

Ordering a full standard sheet is the most economical way to buy the material by area.

However, ordering a custom-cut piece can lead to a lower total project cost. You pay a premium for the cutting service but eliminate material waste and the internal labor cost of cutting it yourself.

Lead Time and Availability

Standard 1200x1200 mm sheets in common thicknesses are typically in stock for immediate shipment.

Custom-cut sizes or sheets requiring special treatments like chemical etching will inherently have a longer lead time. Always factor this into your project schedule.

Material Waste

The most obvious drawback of using a large standard sheet for a small component is material waste. If your project only requires a small 100x100 mm square, purchasing a full 1200x1200 mm sheet is highly inefficient unless you have other uses for the offcuts.

How to Select the Right PTFE Sheet

Your final choice depends entirely on the goals of your project.

- If your primary focus is rapid prototyping or a one-off part: Start with a readily available standard sheet that is large enough for your needs and cut it yourself or by a local machine shop.

- If your primary focus is production efficiency: Specify pre-cut blanks from your supplier to minimize material waste and in-house labor.

- If your primary focus is integrating PTFE into a bonded assembly: Ensure you specify a sheet that is chemically etched on one side for proper adhesion.

- If your primary focus is a very thin, flexible barrier: You may need to search for PTFE film or foil instead of a "sheet," as these are manufactured and categorized differently.

Understanding these dimensions and options empowers you to source the right material form factor for your specific engineering challenge.

Summary Table:

| Standard Sheet Size (mm) | Common Thickness Range (mm) | Key Consideration |

|---|---|---|

| 1000 x 1000 | 0.5 to 150 | Base material for custom cuts |

| 1200 x 1200 (Most Common) | 1, 2, 3, 5, 10, 25 | Best availability and cost-effectiveness |

| 1500 x 1500 | 0.5 to 150 | For larger part requirements |

Ready to optimize your PTFE component sourcing? KINTEK specializes in manufacturing high-precision PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, including cut-to-size sheets and specialized treatments like chemical etching for bonding. Let us help you reduce material waste and streamline your production process. Contact us today for a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability

- What temperature range can PTFE bushes withstand? From Cryogenic -200°C to High-Heat 260°C

- How are PTFE rubber seals utilized in the chemical processing industry? Ensuring Leak-Free Safety in Corrosive Environments

- What is the chemical resistance of Teflon encapsulated O-rings? The Ultimate Guide to Inert Sealing

- How do PTFE lip seals perform in turbocharger applications? Superior Sealing for Extreme High-Speed Environments

- Are PTFE rods compliant with industry standards and regulations? Ensure Your Project Meets FDA, USP & More

- Why are extruded PTFE rods popular in plumbing systems? Superior Chemical & Thermal Resistance

- What is the purpose of dimples on the PTFE surface of these bearings? Enhancing Lubrication and Longevity