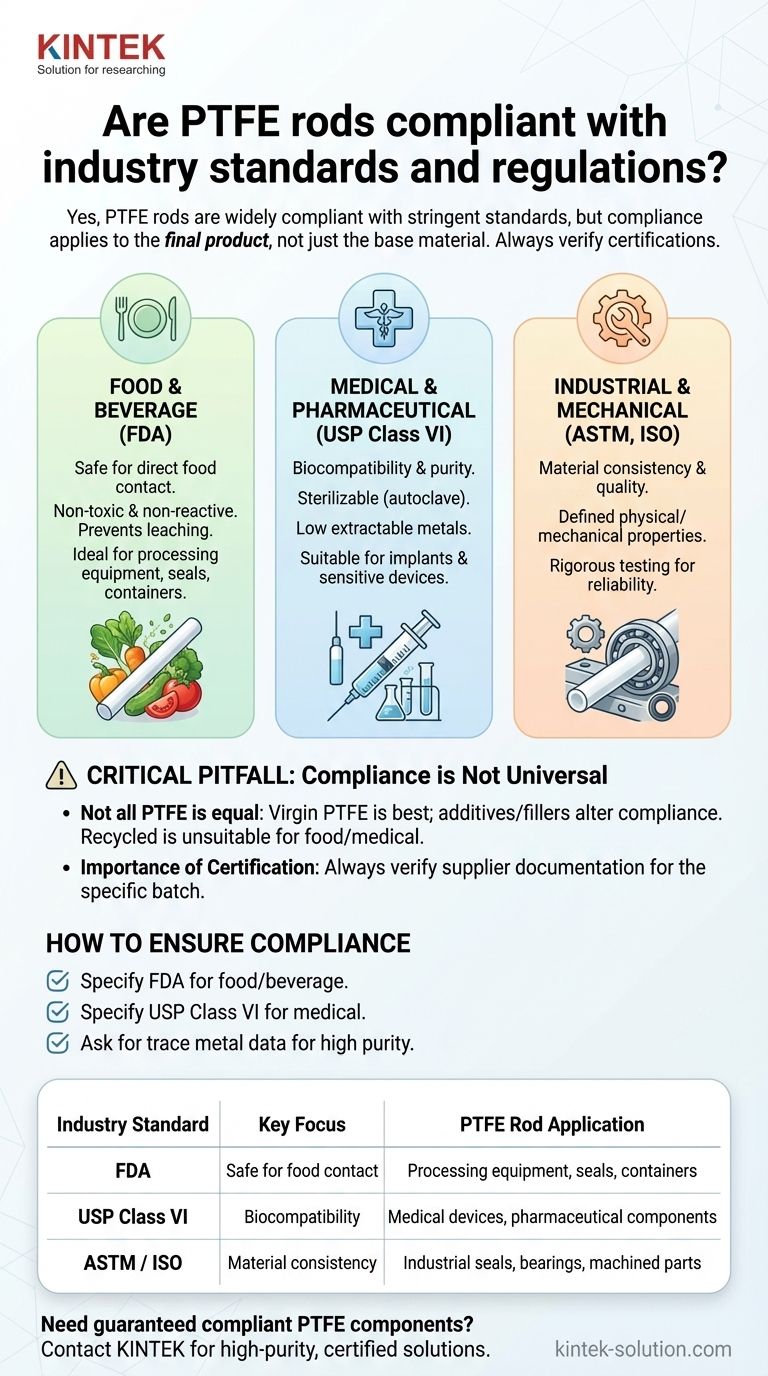

Yes, PTFE rods are widely compliant with a range of stringent industry standards and regulations. Their inherent chemical inertness, non-toxic nature, and purity make them a go-to material for highly regulated sectors, including food processing, medical devices, and pharmaceuticals.

The critical takeaway is that while the base PTFE material is inherently suitable for compliance, the specific standard (like FDA or USP Class VI) applies to the final manufactured product. You must always verify that the specific grade and rod you purchase carries the certification required for your application.

Key Areas of PTFE Compliance

Polytetrafluoroethylene (PTFE) is recognized by multiple global regulatory bodies for its safety and reliability. Its compliance profile is a primary reason for its selection in critical applications.

Food and Beverage (FDA)

PTFE is well-known for its compliance with the U.S. Food and Drug Administration (FDA).

Materials that are FDA-compliant have been deemed safe for direct contact with food products. The non-toxic and non-reactive properties of virgin PTFE prevent it from leaching harmful substances, making it an ideal choice for food processing equipment, seals, and containers.

Medical and Pharmaceutical (Biocompatibility & Purity)

The medical field demands materials that are not only safe but also pure and sterilizable.

Many grades of PTFE meet USP Class VI requirements, which is a rigorous standard for biocompatibility, ensuring the material does not cause adverse reactions when in contact with human tissue.

Furthermore, its ability to be sterilized via autoclave and its extremely low levels of extractable metals make it suitable for pharmaceutical production and sensitive medical devices.

Industrial and Mechanical (ASTM, ISO)

Beyond health and safety, PTFE products adhere to standards that govern their physical and mechanical properties.

Organizations like ASTM International provide standards for testing and specifying plastic materials, ensuring consistency and quality. While a raw rod may not have a dimensional standard like an O-ring (which follows ISO 3601, DIN 3771, etc.), the base material itself is rigorously defined and tested.

Understanding a Critical Pitfall: Compliance is Not Universal

Obtaining a compliant part is more nuanced than simply selecting "PTFE." The responsibility lies in ensuring the specific product you source meets the standard you need.

Not All PTFE is Created Equal

The highest compliance levels, particularly for FDA and USP Class VI, apply to 100% virgin PTFE.

Additives or fillers used to create specific mechanical properties (like glass or carbon) can alter the compliance status. Recycled or reprocessed PTFE will almost certainly not meet these stringent food or medical standards.

The Importance of Manufacturer Certification

A raw material's potential to be compliant is not the same as a final product's certification.

You must always request and verify documentation from your supplier. This certificate of compliance is your proof that the specific batch of PTFE rods you are purchasing has been tested and manufactured to meet the required standard.

How to Ensure Compliance for Your Project

To guarantee success, you must align your material specification with your project's regulatory environment.

- If your primary focus is food or beverage: Explicitly request and verify documentation for FDA-compliant virgin PTFE.

- If your primary focus is medical or pharmaceutical: Specify material that is certified to USP Class VI standards and confirm its suitability for your required sterilization methods.

- If your primary focus is a contamination-sensitive process: Ask for data on trace metal content to ensure the material meets your high-purity requirements.

Ultimately, achieving compliance requires you to be precise in your specifications and diligent in verifying supplier documentation.

Summary Table:

| Industry Standard | Key Focus | PTFE Rod Application |

|---|---|---|

| FDA (Food & Drug Administration) | Safe for direct food contact | Food processing equipment, seals, containers |

| USP Class VI | Biocompatibility for medical use | Medical devices, pharmaceutical components |

| ASTM / ISO | Material consistency & mechanical properties | Industrial seals, bearings, machined parts |

Need PTFE components that are guaranteed to meet your industry's strictest standards?

At KINTEK, we specialize in manufacturing high-purity PTFE rods, seals, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. We provide full material traceability and certifications (FDA, USP Class VI) to ensure your project is compliant from prototype to high-volume production.

Contact our experts today to discuss your specific requirements and receive a quote for certified, precision-engineered PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance