In short, PTFE lip seals perform exceptionally well in turbocharger applications. They are specifically engineered to thrive in the extreme high-speed, high-temperature, and limited-lubrication conditions where traditional elastomeric seals would quickly fail. Their unique material properties make them a superior choice for ensuring long-term reliability and performance.

The core reason PTFE excels is its unique combination of extremely low friction and high thermal stability. This allows the seal to handle immense rotational speeds without generating destructive heat, ensuring a reliable seal over a long service life in a turbocharger's harsh environment.

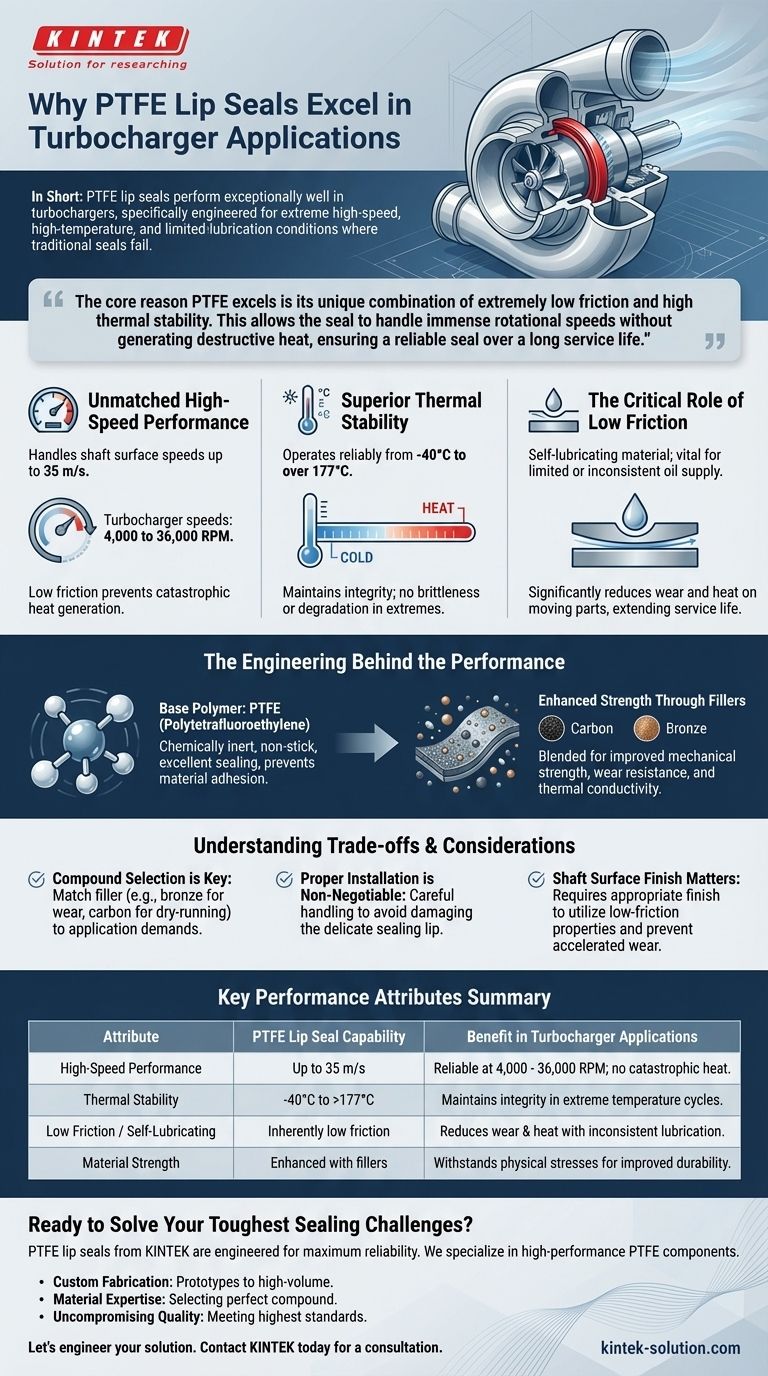

Why PTFE Excels in Turbocharger Environments

A turbocharger is one of the most demanding environments for any mechanical component. The constant exposure to high temperatures, exhaust gases, and rotational speeds in the tens of thousands of RPM creates a challenge that PTFE-based materials are uniquely equipped to handle.

Unmatched High-Speed Performance

A key advantage of PTFE is its ability to handle extremely high shaft surface speeds, up to 35 m/s.

This is critical in turbochargers, which operate at speeds ranging from 4,000 to 36,000 RPM. Unlike other materials, PTFE's low friction prevents the catastrophic heat generation that would otherwise lead to premature seal failure.

Superior Thermal Stability

PTFE seals are designed to operate reliably across a wide temperature spectrum, from -40°C to over 177°C in turbocharger applications.

This inherent resistance to temperature extremes ensures the seal maintains its integrity and sealing capability without becoming brittle in the cold or degrading in the heat.

The Critical Role of Low Friction

PTFE is a self-lubricating material, a property that is vital in applications with limited or inconsistent oil supply.

This characteristic significantly reduces wear and heat generation on moving parts. It ensures the seal functions efficiently even when ideal lubrication isn't present, extending the life of both the seal and the turbocharger shaft.

The Engineering Behind the Performance

The exceptional performance of these seals isn't accidental; it's a result of the fundamental properties of the polymer and the use of specialized composite blends.

The Base Polymer: Polytetrafluoroethylene

PTFE is a synthetic polymer renowned for its chemical inertness and non-stick characteristics. These foundational properties provide excellent sealing and prevent material adhesion to the rotating shaft.

Enhanced Strength Through Fillers

For mechanically demanding applications like turbochargers, base PTFE is often blended with fillers such as carbon or bronze.

These fillers are not mere additives; they are integrated to significantly improve the compound's mechanical strength, wear resistance, and thermal conductivity. This creates a robust material that can withstand the physical stresses of a high-performance system.

Understanding the Trade-offs and Considerations

While highly effective, specifying a PTFE lip seal requires a clear understanding of its application requirements. Success depends on more than just the material itself.

Compound Selection is Key

The choice of filler material is critical. A bronze-filled PTFE may offer excellent wear resistance, while a carbon-filled compound might provide better performance in dry-running conditions. The specific compound must be matched to the precise demands of the application.

Proper Installation is Non-Negotiable

The ultimate effectiveness of any high-performance seal is heavily dependent on the installation process. PTFE seals must be handled and installed carefully to avoid damaging the delicate sealing lip, which would compromise their function.

Shaft Surface Finish Matters

To take full advantage of PTFE's low-friction properties and ensure a long service life, the seal must run on a shaft with an appropriate surface finish. An improper or damaged shaft surface can cause accelerated wear and premature failure of the seal.

Making the Right Choice for Your Application

Selecting the correct sealing solution requires aligning the material's strengths with your primary engineering goal.

- If your primary focus is maximum reliability in a high-RPM environment: A filled PTFE lip seal is the definitive choice due to its superior heat management and speed capabilities.

- If your primary focus is sealing with limited or intermittent lubrication: PTFE's self-lubricating properties provide a crucial margin of safety that other materials cannot match.

- If your primary focus is upgrading from a traditional elastomeric seal: PTFE offers a significant performance boost but requires careful attention to the shaft condition and installation protocol to realize its full potential.

Ultimately, choosing a PTFE lip seal is a decision to prioritize long-term durability and performance in the most demanding mechanical conditions.

Summary Table:

| Key Performance Attribute | PTFE Lip Seal Capability | Benefit in Turbocharger Applications |

|---|---|---|

| High-Speed Performance | Handles shaft speeds up to 35 m/s | Reliable operation at 4,000 - 36,000 RPM without catastrophic heat generation |

| Thermal Stability | Operates from -40°C to over 177°C | Maintains integrity and sealing capability in extreme temperature cycles |

| Low Friction / Self-Lubricating | Inherently low friction, even with limited oil | Reduces wear and heat, ensuring performance with inconsistent lubrication |

| Material Strength | Enhanced with fillers like carbon or bronze | Withstands physical stresses for improved wear resistance and durability |

Ready to Solve Your Toughest Sealing Challenges?

PTFE lip seals from KINTEK are engineered for maximum reliability in the most demanding environments, like turbochargers. We specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver precision and durability by offering:

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Material Expertise: Selecting the perfect PTFE compound (e.g., carbon-filled, bronze-filled) for your specific speed, temperature, and lubrication requirements.

- Uncompromising Quality: Ensuring every component meets the highest standards for performance and longevity.

Let's engineer your solution. Contact KINTEK today for a consultation on your custom PTFE sealing needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications